Cintec, an international structural engineering firm based in Wales, has helped in the restoration of the historical Government building in the Republic of Trinidad and Tobago, the Red House.

This project, undertaken by Cintec’s North American branch, has utilized additive manufacturing for the first time within sacrificial structures and claims to have the longest reinforcement anchors inserted into a structure, measuring at 36.52 metres.

Anchoring and reinforcement with Cintec

With an extensive portfolio of historical building restoration projects, Cintec was approached by Canadian engineering consulting firm WSP and Trinidadian consulting civil and structural engineering firm, C.E.P Limited, to contribute in the $1 million restorations of the Red House.

This project commenced in 2017, following Cintec’s successful restoration work on other high-profile landmarks such as the Djoser Egyptian pyramids, The White House, and the Thorngreen Lime Kilns located in Northumberland, UK.

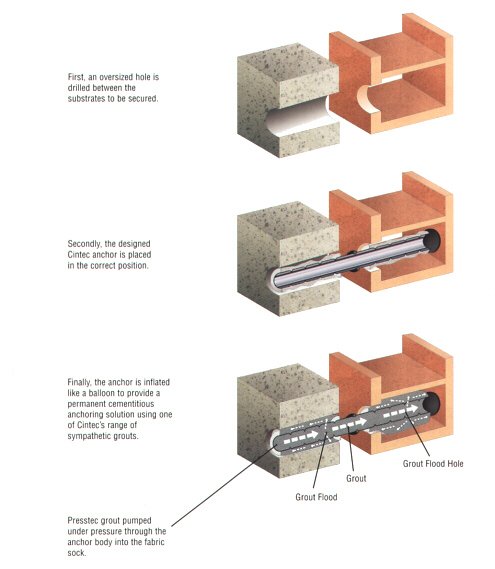

Using the Cintec Reinforcement and Anchoring System, Cintec’s approved contractor, Celtest, pre-drilled oversized holes into the structure of the Red House building to insert its anchor body – a stainless steel hollow section which is used to house cementitious grout.

This anchor, along with Cintec’s reinforcement bars, works as an invisible repair solution to buildings that have previously been through damage caused by natural disasters, which traditional repair anchors cannot achieve. Additionally, this process causes minimal disruption as it eliminates the need for excess road haulage.

“This exciting project, with all of its technical difficulties, illustrates how our anchoring system can be adapted to solve the most complicated structural repairs in order to help restore yet another world-famous landmark,” said Peter James, Chairman of Cintec Group.

The Red House restorations

The Red House, located in Port of Spain, is the seat of Parliament for the Republic of Trinidad and Tobago. Its original structure and the Beaux-Arts style architecture were established during the 18th century and became a famous landmark among the citizens of Trinidad and Tobago.

However, due to a fire in 1903, the famous building suffered significant external and internal structural damage which led to its initial refurbishment in the following year.

In 2007, Cintec also successfully reinforced the external walls of Trinidad’s Queen’s Royal College (QRC) building located in Port of Spain using its Cintec Reinforcement and Anchoring System.

“We spent a great deal of time and used all of our own unique techniques to ensure that the project would be completely successful in restoring such a historic structure to its former glory,” said Robert Lloyd-Rees, Managing Director of Cintec North America.

Additive manufacturing and restoration

In 2017, researchers from the Huazhong University of Science and Technology in Wuhan, China explored the minimally disruptive processes of structural restoration using 3D scanning and 3D printing over traditional methods.

Additionally, British car restoration team, Redesign Sports Ltd (RSL) previously demonstrated the restoration capabilities of 3D printing technologies through its project which used 3D scanning and CAD modeling to reverse engineer a 1952 classic Ferrari.

Keep up with the latest innovations in 3D printing by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the Red House in Port of Spain, Trinidad. Photo Via Wikipedia.