British car restoration team, Redesign Sports Ltd (RSL) have used 3D scanning and CAD modelling to reverse engineer a 1952 classic Ferrari.

Based in St Albans, RSL have implemented 3D scanners in order to perform repairs on rare cars. Founder of RSL, Dafyd Richards spoke to NT CADCAM about the company’s experience with 3D technology and how it has drastically changed their workflow.

“Horrendously difficult” to find old parts

Dafyd Richards explains that 3D scanning has been essential to restoring parts for cars like the 1952 Ferrari 225 since replacement parts are no longer manufactured. As he says,

People wanted to go racing or do long distance tours but the problem was, that irrespective of how much the customer was willing to spend, these £1 million or even £20 million cars couldn’t go anywhere because finding old parts or getting them remade was horrendously difficult.

While money may not be an issue, traditional manufacturing techniques were no longer a viable option. This was similarly the case in restoring the Delage, 103 year-old car. In this example, scanning and 3D printing was used to create an engine block for the 1914 Grand Prix car.

Scanning revolution

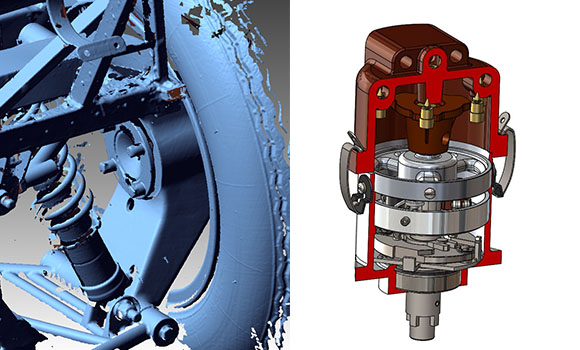

Richards and his team uses a Creaform HandySCAN 700 to create a 3D scan of a car or specific part and then import the data into Solidworks software. Once in Solidworks, the parts will be remodelled and then sent to manufacturers for production. According to Richards, the developments in technology have been dramatic in recent years,

In the last 3-5 years, there has been a revolution and evolution in the scanning technology available.

Richards is in good company opting for the HandySCAN 700, as Creaform announced recently that the scanner has been certified for use by Airbus.

The classic Ferrari 225

Describing the case of the Ferrari 225, Richards states the customer, from the United States, asked them to take a look at the car before it went to the Goodwood Revival. The Goodwood Revival is a three-day car festival that takes place annually in Chichester, UK.

However, when they started the engine the day before the event, the connecting rod in the engine came loose and damaged the engine’s pistons. The connecting rod, or conrod, controls the movement of the pistons in the engine and is therefore a vital component in the engine.

Naturally, the car would not be ready within a day for the Goodwood Revivial, so the car owner’s attention turned to the Monaco Historic Grand Prix. However, this gave the team at RSL only 8 weeks to repair the engine and produce a number of new pistons. Nevertheless, with use of 3D scanning, Richards explains the designs for the parts were sent to the manufacturer in less than a week and just three weeks later they received 12 new pistons.

Interestingly, the Ferrari Formula 1 team utilized 3D printing to develop pistons for this year’s engine.

Fitting together first time

The resulting time between the pistons arriving and the event in Monaco was spent working on the car in a more traditional manner. While 3D scanning had enabled a quick turnaround time and the production of rare replacement parts, the car would still need significant work to get to Monaco. However as Richards explains, the accuracy of the technology proved beneficial,

The parts had only ever been together on the screen in SOLIDWORKS, but when they all arrived they all fitted together right first time. I knew they would but it was still an amazing feeling when they did. The car drove magnificently in Monaco and after a quick check-up back in the UK, it was delivered to Heathrow for its flight back to the USA.

This month the winners of the 3D Printing Industry Awards will be announced and voting is still open to decide the winners.

For the latest 3D scanning news, subscribe to our newsletter and follow us on twitter.

Featured image shows the restored 1952 Ferrari 225 in Monaco. Photo via RSL.