Royal College of Art (RCA) graduate student, Lingxiao Luo, who is pursuing her Masters in Fashion Womenswear, has developed new a fabrication techniques combining 3D printing and traditional knitting.

Formerly a childrenswear designer, Luo created a design concept that would translate the whimsical-nature of objects and novelty products made for kids into functional and wearable products, ultimately representing an extension of childhood.

In an exclusive interview with 3D Printing Industry, I speak to Luo to learn more about her unique process of creating the garments for her AddiToy collection and how it can be used elsewhere in the design world.

AddiToy fabric 3D printed sweater. Photo via RCA.

The fabrication techniques

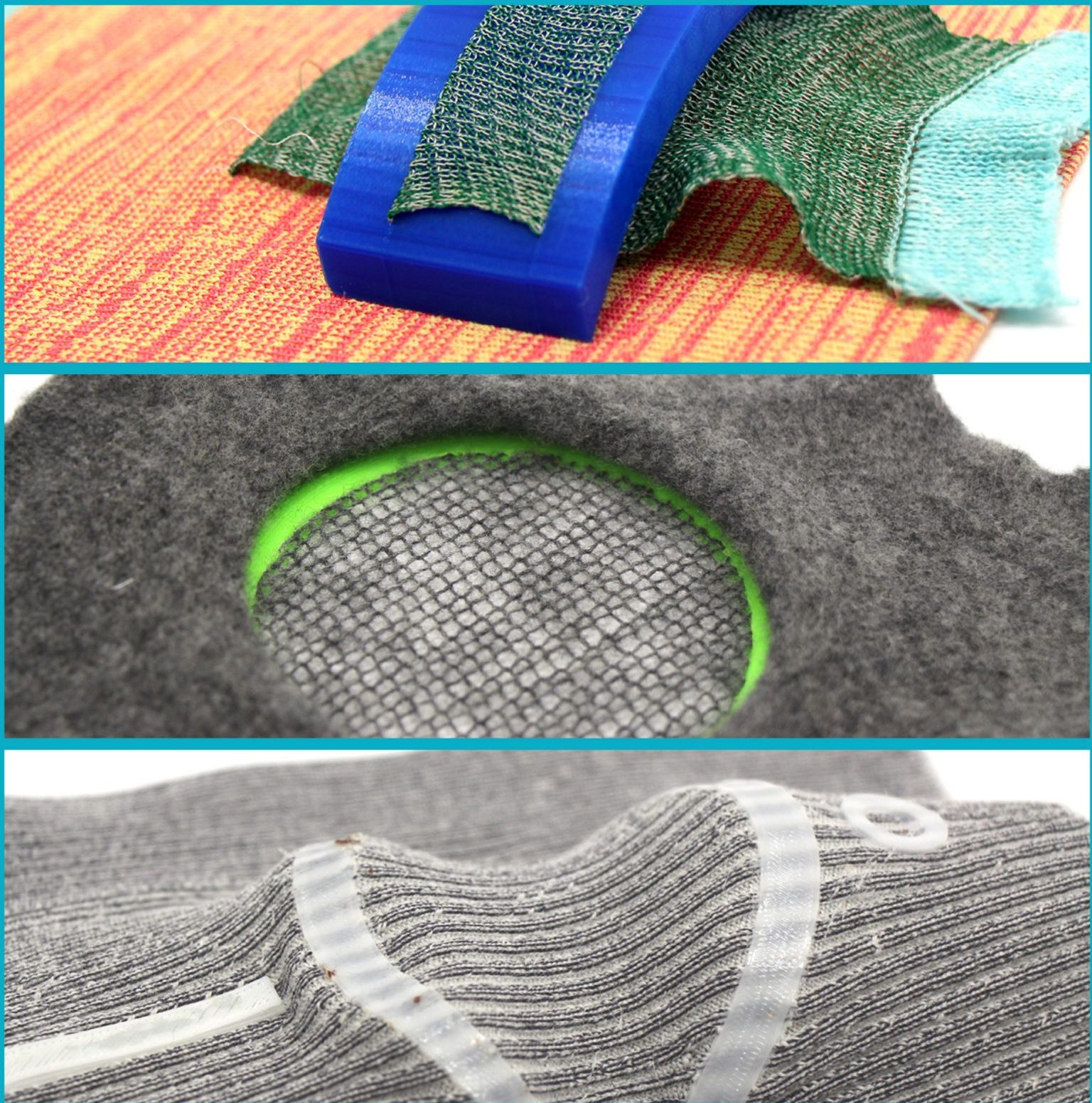

Luo experimented with a variety of fabrics and filaments which gave her garments different finishes each time.

The first technique used was joining. This involved 3D printing mesh patterns directly onto fabric in order to attach two separately knitted yarn pieces.

Secondly, Luo used a felting method which allowed her to weave 3D printed patterns of filament onto loosely-knitted fiber fabric. The material then goes through the felting process which wets and shrinks the fabric, producing a three-dimensional structure.

Luo’s final technique was twisting. This involved printing flexible filament such as TPE onto a tightly knitted elastic fabric.

“Depending on the functions that I’m looking for, the making duration can vary a lot,” explains Luo, “Usually, it takes me 6 to 12 hours to knit the base, 1 to 3 hours to build up the 3D files and then 3 to 5 hours to print.”

“For example, the blue top with 3D printing details on the sleeves took me 8 hours for knitting and 4 hours for printing, the printing file was really simple so it just took me 30 mins to built up”.

3D printed for comfort

Comfort and wear-ability were two of Luo’s major concerns when creating her garments. Although her methods and overall collection designs are unique, Luo had to consider its practicality within the fashion industry.

“3D printing can offer the knitting more structure and the knitting can make the 3D printing more wearable, that’s the starting point of my technique!”

“The PLA and ABS filaments that I’m working with are still quite solid and couldn’t be largely used around the body. However, the TPE one is much more flexible. When the 3D printing is just a thin layer on the knit, it’s super stable and wearable just like embroidery or stamping.”

During her fabrication processes, Luo also found new filaments that were soft and flexible which she plans on trying out on future garments. Luo believes that her techniques can be used within other clothing collections to obtain that bold and playful aesthetic.

Luo showcased her AddiToy collection at the Royal College of Art MA Fashion show at the 180 The Strand, earlier this month.

Previous research published by Carnegie Mellon and Rochester Institute of Technology(RIT) has explored the use of a 3D printer to create stronger and more functional textiles. Additionally, a study published by the Swedish University of Borås; French universities GEMTEX and Université Lille Nord; and the Chinese College of Textile and Clothing Engineering have investigated the methods and outcomes of direct 3D printing of PLA onto fabric.

Keep up with the latest innovations in 3D printing materials by subscribing to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows knitwear fabric samples using 3D printed filaments as mesh. Photo via Royal College of Art/ Photographer Daniel Sims.