Italian research institute Politecnico di Milano is directing an international consortium aimed at increasing resource efficiency in the automobile and construction industries via metal 3D printing.

According to the European Commission, the demolition and building industries generate 30% of all waste generated in the EU each year. It is hoped that AM technologies will “herald a new era” of enhanced customization and optimization, as well as enable companies to decrease energy and waste during the steel production process. The research study at Politecnico di Milano aims to reduce the sector’s carbon footprint, as well as that of the automotive sector, using novel steel 3D printing technology.

“Given around one-third of all the waste produced around the world each year comes from the construction industry, steel production has a major role to play here,” said project coordinator Dr. Alper Kanyilmaz. “The current manufacturing techniques available are not easily optimized, and there is a lot of material wasted. For example, during the cutting and welding of steel plates. Also, using conventional construction techniques, a lot of material is used where it isn’t needed and placed in unnecessary spots.”

How will this research project facilitate waste management?

“When we talk about additive manufacturing, there are already some very interesting outcomes in other industries. For example, some small houses are being built via this method with concrete. Steel comes into play in printing critical components that can be integrated into larger structures,” added Dr. Kanyilmaz.

ConstructAdd is a European Research Fund for Coal and Steel-funded project that brings together enterprises, technology, and research institutions from five European countries to enhance resource efficiency in the steel manufacturing industry. ConstructAdd particularly aims to demonstrate that the introduction of metal 3D printing can reduce waste throughout fabrication while also saving energy by an estimated 30%.

“The main objective of ConstructAdd is to bring metal 3D printing technology into the mainstream of the construction and automotive industries. Why? Because the current objectives of governments worldwide, and society as a whole, are reducing carbon emissions and dealing with waste problems,” stated Dr. Kanyilmaz.

He further explained that these concerns, which are major challenges for the construction industry in particular, cannot easily be solved with conventional techniques, simply because conventional techniques were invented for problems of the past.

3D printing customized parts and joints from scratch eliminate the waste of scrap metal that would normally be produced as a byproduct of constructing parts from an existing steel plate. It will additionally enable process optimization and increased flexibility on the side of construction companies, which will be capable of printing certain parts on-site instead of depending on transportation. Steel 3D printing is particularly appealing due to its importance in the construction industry, thanks to factors such as its high flexibility, strength-to-weight ratio, versatility, and tensile strength.

“Steel is far more resistant and ductile compared to other materials. So, it offers more opportunities to manufacture more complex geometries which can withstand higher stress and fatigue loads. In any future where 3D printing becomes mainstream in the construction industry, steel will maintain those advantages. That is what makes developing additive manufacturing technology in this area so attractive,” explained Dr. Kanyilmaz.

Furthermore, ConstructAdd project partners include the IMDEA Materials Institute in Madrid, the University of Pisa, RWTH Aachen, Prima Industrie S.p.A., BLM Group, Det Norske Veritas, CIMOLAI SPA, VALLOUREC, MIMETE, and ArcelorMittal Vitry, in addition to the Politecnico di Milano.

Can additive manufacturing help with waste management?

Previously, resin printing system manufacturer Onulis launched WRAPCure, a dual-purpose device that automatically post-curse Digital Light Processing (DLP) printed parts and recycles waste resin. The original WRAP product line from Onulis instantly converts utilized UV resin into fully-cured plastic stock, yielding materials that can be CNC machined and are safe for disposal as common household waste. Consequently, the device is intended to provide a low-cost, environmentally friendly alternative to harmful waste disposal techniques. The novel WRAPCure maintains all of WRAP’s sustainable waste printing features while also allowing users to post-cure DLP parts.

Furthermore, Filaret, a developer of sustainable 3D printing materials, partnered with Estonian authorities to repurpose discarded cigarettes from the country’s shorelines into filament. As part of a local government program in Estonia’s capital Tallinn, special litter bins were installed along some of the city’s beaches, where the people were encouraged to discard cigarette butts. Tallinn Deputy Mayor Joosep Vimm said, “I hope that these special cigarette bins will help to reduce this widespread marine litter. What makes the project particularly interesting is that, in addition to just collecting the cigarette butts from the beach, they will be upcycled into compostable 3D printing material, thus reducing the problem of plastic waste.”

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

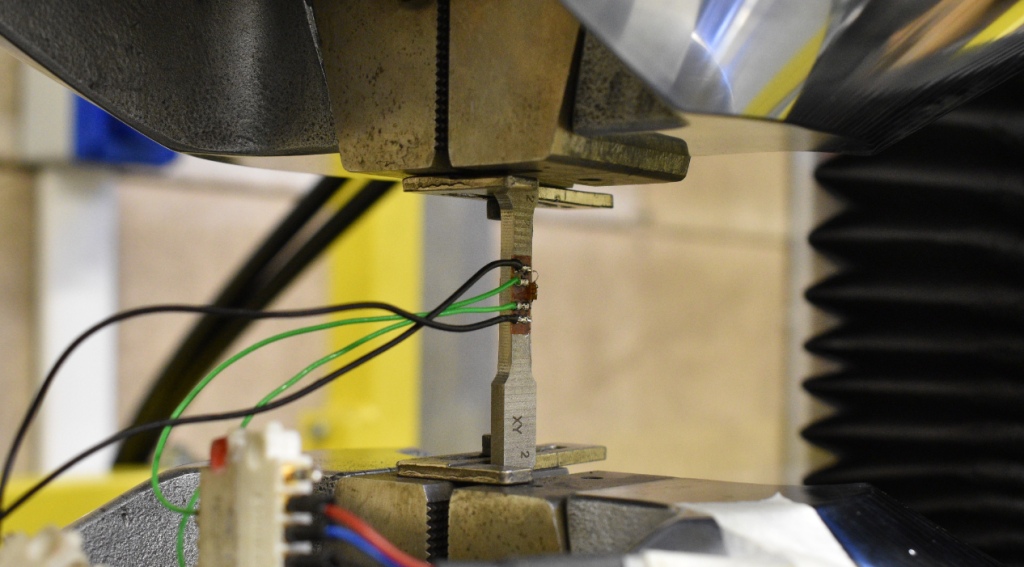

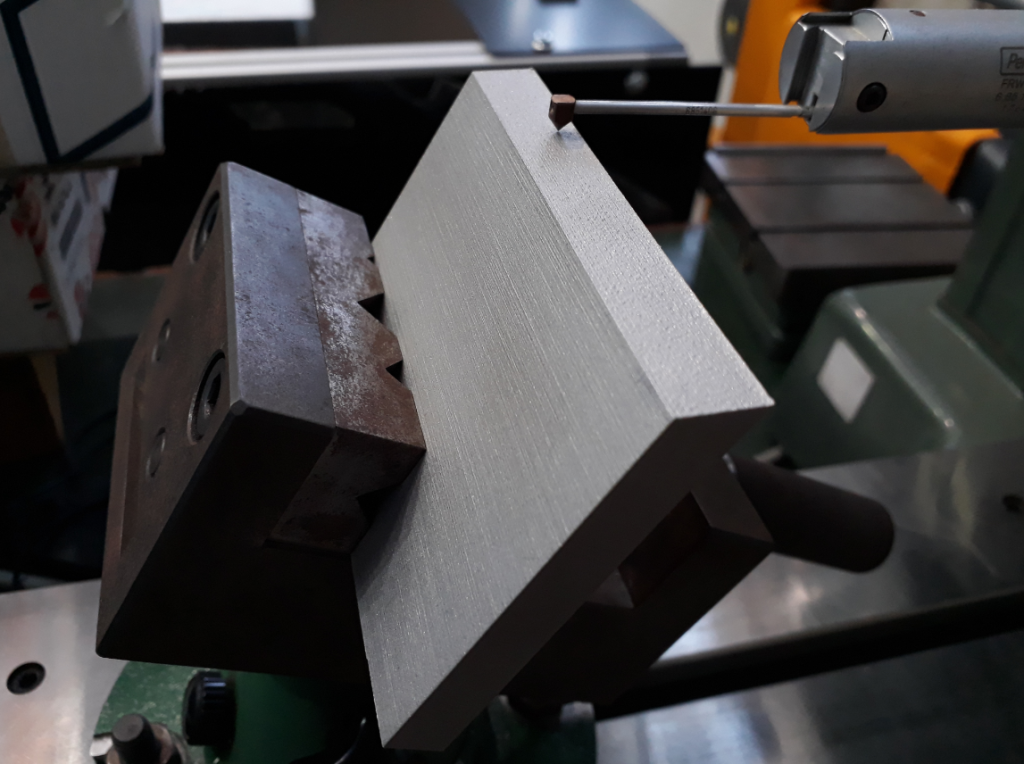

Feature image shows 3D printed steel mechanical characterization test. Image via IMDEA.