Cetim, the French Technical Center for Mechanical Industries, has released a new steel grade for the Laser Powder Bed Fusion (LPBF) additive manufacturing.

Characterised as 33CrMoV12 steel, this material is designed for parts enduring nitriding, a hardening heat treatment that diffuses nitrogen into the surface of a metal. Such nitrided parts feature mechanical properties suitable for the power transmissions sector.

Steels for additive manufacturing

As a result of extensive R&D work carried out on behalf of French manufacturers, engineers at Cetim have added 33CrMoV12 steel to three steels already commonly used for LPBF manufacturing. This includes X2CrNiMo17-12-2 (316L) and X5CrNiCuNb16-4 (17-4PH) stainless steels and the X2NiCoMo18-9-5 steel (maraging 300).

According to Cetim, these three steels can be easily welded due to their low carbon levels (approximately 0.05 %), however, this is not the case for the new 33CrMoV12 grade which has a carbon percentage as high as 0.36 %. This type of powder must be preheated before additive manufacturing, which can be time-consuming.

It has also been recognized that existing additive manufacturing preheating systems offer temperatures around 200°C, which is below the required temperature of 500°C. To overcome this limitation, the company is specifically determining the LPBF parameters.

Accelerating metal 3D printing

In collaboration with French additive manufacturing specialists Volum-e, Cetim conducted tests on its new steel using finely adjusting the parameters of the process. This resulted in the creation of several test specimens that were then analyzed.

The test was deemed successful for LBPF and displays that the steel 33CrMoV12 has mechanical performance that is higher than that of the same steel when laminated.

Active in a range of additive manufacturing areas, earlier this year Cetim began a partnership with Swedish binder jetting metal 3D printer manufacturer Digital Metal to advance industrial 3D printing. As a result, Cetim was one of the first customers to install a Digital Metal 3D printer, at its Saint-Étienne facility in 2017. Prior to this, the partners began working together in a project launching a fully automated metal additive production concept.

Have you signed up to our free 3D Printing Industry newsletter yet? If not, subscribe today!

Also, get the latest news on our Facebook and Twitter social media channels.

Looking for your next additive manufacturing career move or searching for new talent to join your team? Visit our 3D Printing Jobs site now.

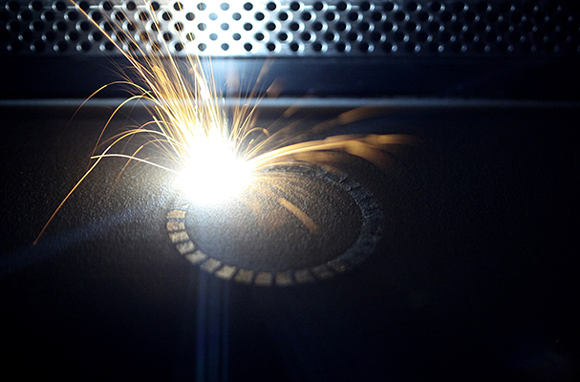

Featured image shows A metal 3D printed globe model. Photo via Cetim.