Components designed for use in aerospace require precision and reliability. 3D printing has been providing both of these for parts used in commercial rockets and planes. Now, a New Jersey engineer wants to make rocket science open source and 3D printable for everyone!

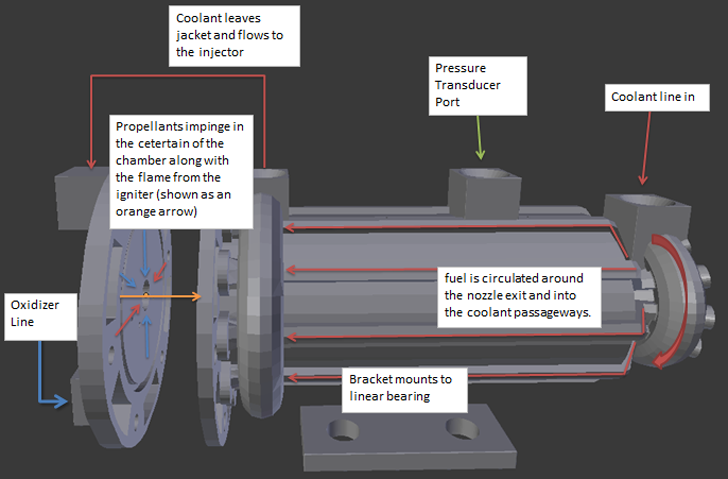

Graham Sortino, a member of New Jersey’s Fair Use Building and Research (FUBAR) Labs, wanted to apply the concept of regenerative cooling to make a 3D printed, liquid-fueled, rocket engine. Regenerative cooling utilizes the engine’s fuel to double as a coolant. Vertical channels of fuel run through the walls of the engine, and lead back to the fuel tank. This helps lower the stress induced by high temperature on the engine. The ultimate goal is to achieve steady-state conditions in the engine. This makes it so the engine can be engineered for the expected conditions, and overheating can be avoided. By heating the fuel, the fuel gains thermal energy. This means that it takes less energy to combust, and thus leads to a slight increase in the engine’s performance.

Sortino considered both Direct Metal Laser Sintering (DMLS) and Selective Laser Sintering (SLS) for the production of his parts. DMLS can produce denser parts with a higher resolution than SLS, so it was clear that DMLS was the best choice for the application; however, SLS is significantly cheaper and fit Sortino’s budget.

The most challenging part of the project, so far, has been making the coolant channels. In the original design, there are ten tubular coolant channels that are evenly distributed throughout the main engine’s body. Unfortunately, leftover powder from the printing process has been getting stuck in the channels, and then becomes clogged when bronze is infused.

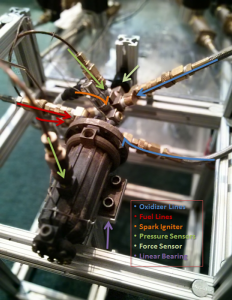

The first engine was completed last summer, and testing began in the fall. Due to the clogged coolant channels, lower oxygen flow rates, and a few other flaws, the performance is a bit lower than the calculations originally predicted, but it’s still very impressive!

Graham has uploaded all of the STL files and design parameters to GitHub, so you can print your very own rocket engine! In the end, the total build cost was roughly $400, but Graham wants to get the cost under $200, so be sure to check back for updates. Not a bad price for your very own rocket engine!