Design and technology initiative Diyouware, set up by two brothers in Spain, is working on a new 3D printing technique named Resin Deposition Modelling (RDM). The technology essentially merges SLA 3D printing with the commonly used FDM process, adding new design possibilities to the process.

Do-it-yourself-ware

The name Diyouware stands for “do-it-yourself-ware” which is a testament to the group’s aims. The two brothers, based in Madrid, set up the company to design “open-source, low-cost, easy to manufacture robotic tools which help people all over the world to build industrial quality things at home and by themselves.”

Resin Deposition Modelling

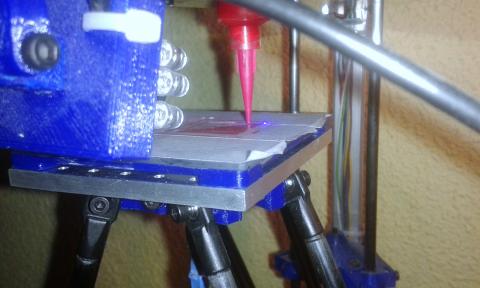

For their prototype 3D printer, Diyouware uses a dispenser and a needle to deposit UV curable resin and cures the material with a laser diode.

Since the technique aims to combine an FDM method of depositing material layer-by-layer and an SLA method of curing resin, Diyouware has referred to the process as RDM. However, as RDM uses laser rather than light, they point out “the correct term could be UV Resin Laser Deposition Modelling, but is too long and Laser Deposition Modelling has been already used.”

Creating 3D structures

Currently, the pair use a 0.25 mm ID needle but believe there is room to use smaller needle sizes to improve detail even further. This is because they are using a resin which is not very viscous and so does not need to be extruded from a thick needle point. Diyouware uses a DLP resin developed by Italian company Robotfactory, who manufacture SLA and FDM 3D printers.

To cure the resin immediately, the machine houses a 100mw/405nm laser diode beam which is able to follow the needle directly as it prints. This element is essential to create 3D structures as the resin needs to harden quickly to allow the next layer to form on top of it. The due have not yet released any phots of objects 3D printed on the machine.

Maker community

The Diyouware team develop these machines in their spare time, however their innovation showcases the power of the maker community. This is something that was apparent when 3D Printing Industry took a close look at the Fab City concept in the Spanish city of Barcelona.

Elsewhere in the Maker community RepRap enthusiast Torbjørn Ludvigsen has similarly crafted his own 3D printer in the form of the Hangprinter. We interviewed Ludvigsen about his creation after he 3D printed a 4.5 m tall tower of Babel.

What’s next for Diyouware

As yet the future of Diyouware is unclear, but they do say,

It is just a prototype. We developed the mechanics, electronics and firmware for the toolhead, and now we are conducting some testing. The first results are promising, but there is still too much work ahead, and as you know the devil is in the details.

Vote for your favorite 3D printing innovation in the 3D Printing Industry Awards.

For the latest 3D printer news, sign up to our newsletter and follow us on twitter.

Featured image shows Laser curing resin on the RDM prototype machine. Photo via Diyouware.