There are people in this world that push the boundaries and strive for better on a daily basis. Miguel Sanchez is one of those people. One of the most frustrating hassles in desktop 3D printing is when small errors occur during a print job due the open loop on which the printers run. In the end, these smallerrors may end up ruining a long print job. Stepper motors are the mainstream solution to the problem, but they have been known to skip a step on occasion, as well. Unlike open-loop control, closed-loop control would rely on feedback from the printing process to inform the printer’s movements, leading to better repeatability and quality assurance in the world of desktop 3D printing.

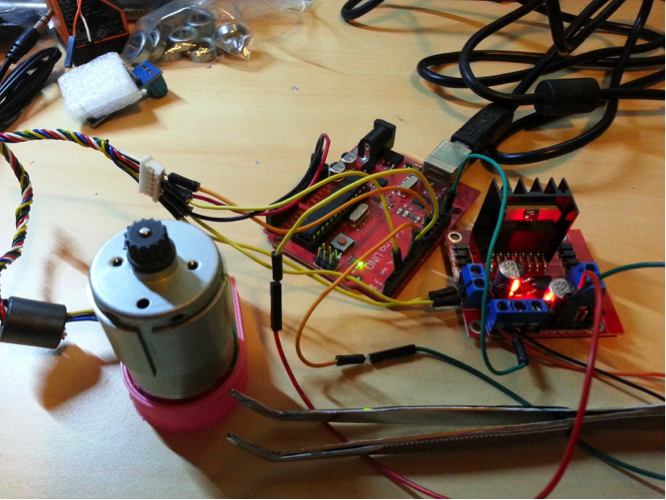

One alternative solution to the problem, that has been floating around internet forums, is the idea of implementing a DC motor with an encoder into the printer’s architecture, instead of a stepper motor. The results could be a machine that is cheaper and more reliable.So Miguel decided to test it out.

Through trial by fire (literal fire –see the original blogpost here), some technical know how, and some custom 3D printed motor mounts for his new DC motor, Miguel achieved some impressive results. In the video below, you’ll see how he can push the printer head out of place and it snaps back into the correct position to continue printing.

The world of 3D printing is forever changing and that is a good thing. Change is the only constant in this world and it provides a platform for the innovators, the seers, the doers, and more people like Miguel to speak their purpose. The community of 3D printing is amazing and filled with people ready to challenge outdated institutional beliefs and outdated thinking. This will help bring us to a new era of awareness and provide the inspiration and courage for others to do the same.