For the longest time, South Korea was a virtual 3D printing desert. As a writer for 3DPI based in Busan, I really had to search far and wide for leads…any leads, to write about. Thankfully, that has changed and Korea is rapidly gaining ground on more developed markets, and is starting to really sort itself out.At the end of last year, there were but a mere handful of 3D printer companies in Korea, the most well known of which wereRokit, OpenCreators, Anatz, and Carima. There are a few others, but they hadn’t really made very deep inroads yet.

Along with these current hardware producers, there is a host of individuals and smaller firms actively contributing to the “maker environment”, which includes software producers, designers, makers, educators, retailers, and coordinators. All of these individual players are now beginning to coalesce into a solid economic sector that is now attracting substantial public attention.

Articles on 3D printing now appear regularly on Korean television, in mainstream newspapers, on the web, and actual printers and services are becoming more and more common in everyday life. This, in turn, is beginning to draw the attention of older, wealthier companies and business people whoare now smelling the first serious whiffs of money swirling in the economic zephyrs surrounding this technology, and they want in…giving smaller companies and startups access to much needed capital and resources.

What does all this mean to you and me? It means that things in East Asia are just getting started, and, once they do, hold on to your hats. New companies will be born and older ones will break up…and their money, and intellectual properties, and talented human resources will move freely around as various cliques form, break apart, and reform.One of the first of these talent reformings is the new printer company ‘Moment’ that I found at the G-Star.

In any case, Mr. Park and several other talented employees decided to leave. Upon their exodus, they formed the core of what has now become Moment. Mr. Park told me that, while the Rokit machines are very good, he felt there were some quality and engineering issues that were being unaddressed. As a professional engineer, who was also in charge of sales, he believed that Rokit was doing its customers a disservice by not addressing these issues prior to marketing and shipping their products.

He wanted to do things differently. Focusing on the quality of the machines was paramount to him, so for the first few months Moment was in ‘stealth mode’, quietly developing their first printer and working out every bug they could find. They had done no marketing, no advertising, and no publicity. An exception was made for a few company partnerships, however,with the purpose of testing the machine in the “real world”, under actual user conditions with real users and to see how fast, or how badly, they could break the machines. This is how I came to stumble across them atthe G-Star show.

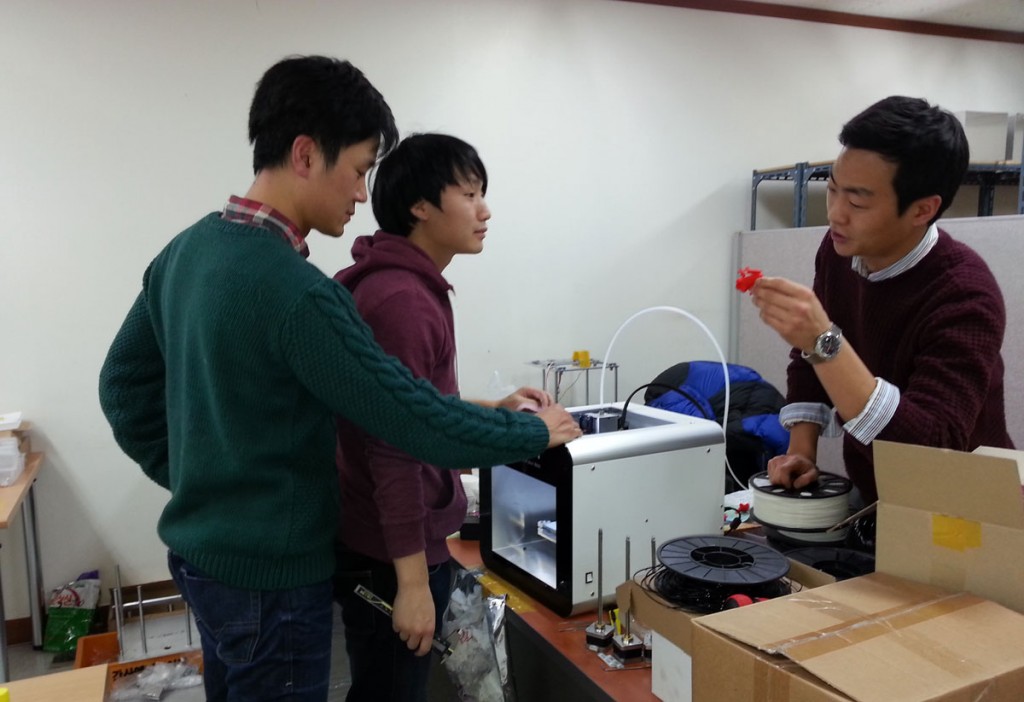

After G-Star,my colleagueDavid Park began researching Moment’s activities and wrote a follow up story about what they had been up to since their formation. While he was working on that, I made an appointment to visit Moment’s new headquarters in Seoul to take a look at this company in person. When I arrived on a cold Wednesday afternoon,Mr. Parkfirst introduced me to Chang HyunAm, one of his chief marketing team members. They then proceeded to show me around, introducing me to the other members present.

They seemed excited (and somewhat determined) to show me their new factory and design facilities. The visit had a distinctly different feel from my typical factory visits, in that normally companies are somewhat guarded about reporters. This is somewhatunderstandable as they really have no control on what we can or will say about them once we leave. Here, there didn’t seem to be any fear…just excitement, enthusiasm, and pride.

Their factory space was clean and well laid out, but a bit small for such a fast growing company. Mr. Park advised me that he was making arrangements to relocate their production section into a new facility that would be custom designed for them. As the Moment printer is constructed almost entirely from aluminum, he wanted a space when the metal work could be isolated from the electronics and packaging areas. At the time of my visit, though, these operations were being conducted in separate areas under a single roof.

In the fabrication section, I saw several machines in various degrees of completion…and what appeared to be a new prototype (More on that later). In the other half of the space, they had their design, packaging, and administrative sections. Their lead engineer, Song Han Hyun, was busy designing what appeared to be a new part to a printer, which to me looked like an improved build plate for their machine.

We then walked into their design studio where I met Jung Sang Hun, their chief designer in the Seoul office. (They have a second office in Busan run by Kim HyungSeok, who I met later and will talk about in part 2 of this story.) I was shown several of their latest test prints and designs. The models they were building seemed to be focusing on objects that had a lot of overhangs and bridging components as part of their designs. The results would then be used to help calibrate the machines. As Mr. Kim explained to me, “We want our machines to be easy for average users to use. While makers love to challenge themselves and their machines, normal consumers don’t…they want something that works, and works at the level of their expectations…or at least close to it.”

In another section,some team members were busy writing the new user’s manual – in English. As it turned out, they had received a sizable order from Australia and a Korean user’s manual, no matter how good it was, wouldn’t do. Such is life in international commerce, and they seemed to be embracing it wholeheartedly. I was told that manuals in other languages are planned, and will be produced as sales expand. They also made sure to tell me that a new English language version of their website was under construction and should be ready soon. There current web address (in Korean) is www.moment.co.kr and they can be found on Facebook.

At this point, Mr. Park gave me a personal demonstration of the machine – but then he did something that caught me completely off-guard. He offered to allow me to “borrow” one of his new machines and test it…in my own lab…without any company supervision! As you can imagine, to say I was surprised would be a gross understatement! I (naturally) accepted his offer and took the machine to Busan for testing, but before I left, I was given a quick in-service on the operation of the machine.

This new company is now coming out of the shadows and actively marketing their new machine. This month alone they attended a large educational trade show in Seoul called the EduKorea Fair and will be going to the Brunei Consumer Fair later this month. The Brunei Fair, held twice yearly, is one of the biggest new consumer product shows in all of Asia.

Currently, they have already shipped their machines to Australia, The Philippines, Brunei, Japan, China, Taiwan, India, Singapore, Indonesia, and Malaysia. They’ve even shipped to a few non-Asian countries, namely England, France, and Russia. Mr. Park told me that he is in discussions with representatives in several other countries now, so that list may be growing soon, and they have plans to go global, as word of their company and reputation spreads.

And if the confidence and pride they have shown in their creation is any evidence at all of the quality and value of their machines, we should see this dynamic bantam weight company grow into a global 3D printing leader in the near future.

In part two of this story I will review the Moment printer in detail, giving you both a complete description of the machine’s construction, user’s experience, and output quality. Since I was able to test the machine without any company oversight, I was able to do some things that may have made the factory reps a bit nervous, but which anyone thinking of buying a new printer may appreciate. Keep an eye out for next portion of this story in the near future.