BORN Motor Co. is an independent, custom motorcycle kit design studio based in Barcelona. By adding a BCN3D Sigma 3D printer to its toolkit, BORN has been able to realize complex, previously impossible, components for its sharp, deconstructed bike models.

As an added bonus, 3D printing these parts also saves a significant amount of time and money in the process, delivering bikes to customers at a much more expedient rate.

Driving focus

3D printed end-use parts at BORN are primarily found as internal and non-aesthetic applications. Depending on use, the parts are made from either Nylon, PET-G or ABS filament.

According to BCN3D, “3D printing is now part of the daily life at BORN Motor, empowering its designers to create more complex parts with a fraction of the previous effort, time and money.”

“While before the staff were spending time in handcrafted components, now they can focus on higher added-value parts.”

€6 down from €1,500 per part

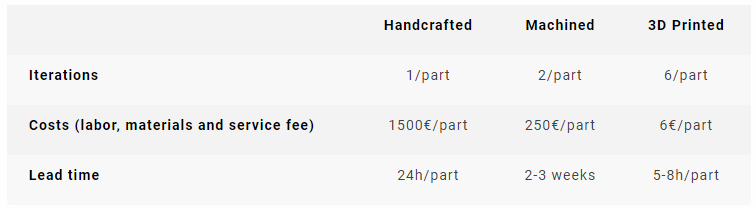

In addition to proprietary kits, BORN Motor designs limited editions cycles and upgrades for existing bikes. As an example upgrade, BORN breaks down the cost to produce a speedometer dash housing for a Honda CB25. Against typically handcrafted and machined parts, the 3D printed alternative is the clear winner across the board for number of possible iterations, costs (including labor, materials and service fee), and lead time.

On average, the 3D printed part undergoes 6 custom iterations, can be produced at a rate of 6 – 8 hours per part, and costs around €6 in total. Machining the part, by comparison takes 2 – 3 weeks, with 2 iterations and costs €250. Handcrafting the part, as previously done at BORN, would set the company back even further at a cost of €1,500 per part, a lead time of 24 hours, and only one possible iteration.

On average, the reduced costs leads to a saving of €2,000 per custom built bike.

The bespoke approach

3D printing is an attractive alternative to bespoke manufacturers like BORN as it allows a design freedom unavailable with any other manufacturing method. In many cases, the technology also creates significant weight savings critical to vehicle performance.

The Light Rider from Airbus’ APWorks is perhaps one of the most famous examples of the potential of 3D printing for motorcycles. A number of supercars have also been developed with the help of 3D printers, and larger car manufacturers are adopting the technology to dramatically reduce tooling and inventory costs.

To keep up with all the latest trends in additive manufacturing, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Get involved with 3D printing events near you here.

Featured image shows a BORN Motor Co. custom kit bike. Photo via BCN3D