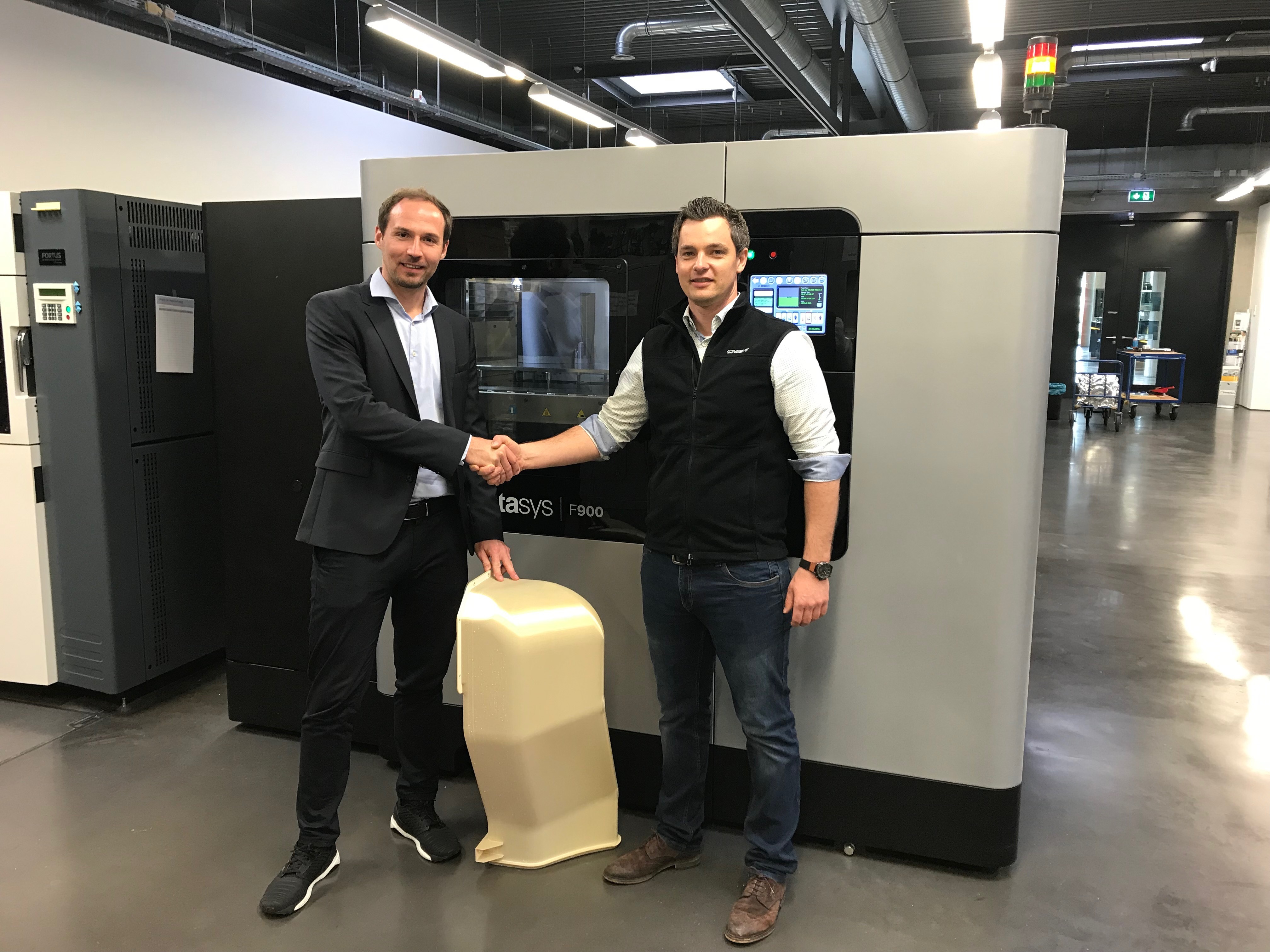

German rail company Bombardier Transportation has installed a Stratasys F900 3D printer at its Hennigsdorf facility, north-west of Berlin.

The F900 FDM/FFF printer will be used for the production of tooling, prototyping, and end-use parts for trains and trams. The parts will be included in Bombardier’s manufacturing operations for DACH countries including Germany, Austria, Switzerland.

André Bialoscek, Head of Vehicle Physical Integration Hennigsdorf at Bombardier, said, “The Stratasys F900 3D Printer allows us to widen our service offering in such a way that we are now able to 3D print large spare parts, customized rail parts, and manufacturing tools – all in-house and on-demand.”

On the tracks of Bombardier Inc.

Founded in 1942, Bombardier began as a manufacturer of snowmobiles. The company is now global and one of the largest manufacturers of aircraft, trains, commuter subways, public buses, and other industrial vehicles like snowcat, a tracked vehicle for moving on snow.

Bombardier Transportation is a rail equipment division of Bombardier Inc. It manufactures passenger trains, locomotives, chassis for trains, controls and propulsion systems. In 2001, Bombardier Transportation acquired the German rail equipment manufacturer Adtranz from DaimlerChrysler. With this acquisition, Bombardier Transportation became the largest rail equipment manufacturer.

With the installation of the Stratasys F900 3D printer, Bombardier Transportation expects significant gains. Bialoscek said, “Having previously used fiberglass and tin for train components, the ability to now utilize ULTEM 9085 resin meets our application criteria and takes us to a new level in terms of reducing the costs and lengthy lead times associated with those traditional materials.”

3D printing in railway

With initiative’s such as this from Bombardier, the Mobility Goes Additive project from Deutsche Bahn, and a commitment from Angel Trains and ESG Rail it is safe to say that 3D printing’s application on the railways is gaining traction.

Adding further insight Andreas Langfeld, President EMEA Stratasys, said, “Bombardier Transportation’s investment in our F900 3D Printer is synonymous with the huge interest we’re seeing in the mobility sector for industrial-grade 3D printing solutions […] We look forward to working closely with Bombardier Transportation to support the deployment of this technology within their operations and enable them to produce customized rail parts on-demand – faster and more cost-effectively than ever before.”

“Our FDM-based additive manufacturing technology offers rail companies and maintenance service providers advanced, rail-certified materials, large build trays for bigger rail parts, and importantly, the highest level of print reliability and repeatability in the industry.”

Vote for your Application of the Year in the 2019 3D Printing Industry Awards.

Join us on Facebook and Twitter to get live updates on how additive manufacturing transforming the railway and subscribe to our newsletter.

Start a career in manufacturing by registering with 3D Printing Jobs.

Featured image shows an LRC locomotive, manufactured by Bombardier Transportation. Image via Bombardier Transportation