Among the many paradoxes in the upcoming revolution of personalized goods is that, for physical products to become more tailor made what first needs to happen is an evolution of our digital selves. What this means is that if we want to have clothes, sporting apparel, medical items and generally wearable technology that is made just for us we first need to have a digital alter ego roam the web to go try it on.

Lower Manhattan (Silicon Alley) based Body Labs is the company working on developing that 3D digital self. Surprisingly – although 3D scanning is starting to pick up momentum – there are not many companies developing the software architecture necessary to take those 3D scans and make them into “real” digital people that can move, adapt and try on bespoke digital products before they are 3D printed on demand.

Although it is not the only one and it is probably not the most strategically important, the apparel industry is the first place where Body Labs technology is being implemented and is one of the reasons why the 10-person start-up decided to make New York City its base. Since regular clothing fibers cannot yet be 3D printed, all clothing prototyping activities need to be carried out digitally to reduce costs and – although there still are severe limitation in the development of digital clothes that can fit on digital people – Body Labs has developed algorithms that make the digital person’s movement appear more natural even with certain clothing items on.

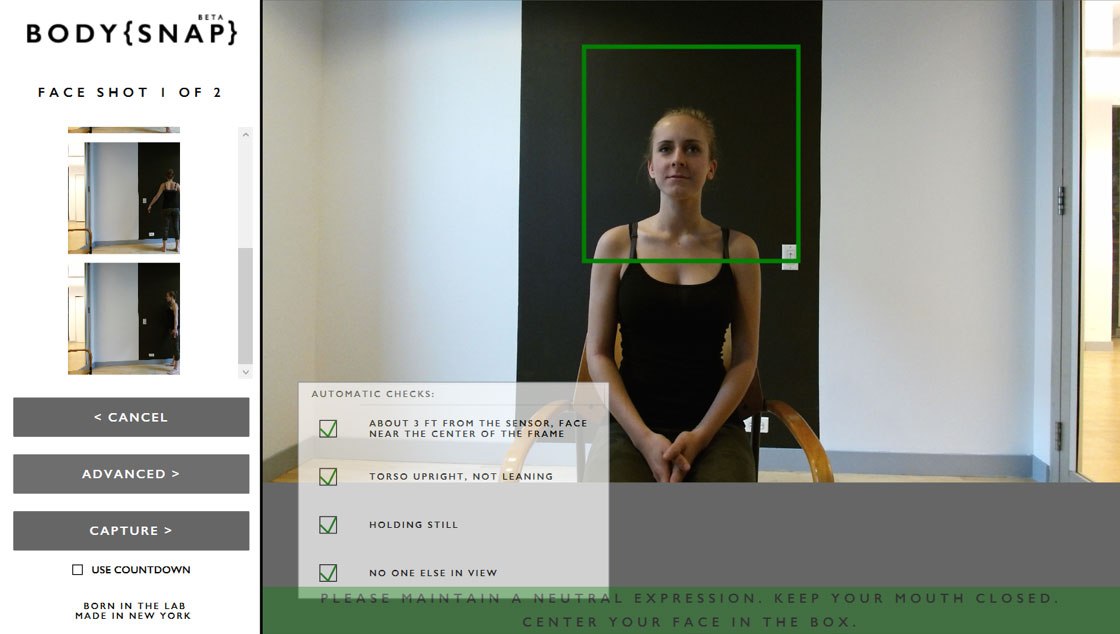

In fact the company has already begun working with tailors and, in general, the B2B segment remains dominant in its business model. Even the Body Snap App it launched a few months ago to let consumers use the Kinect V2 system by Microsoft to create their digital selves is intended more as a tool for use in gyms and/or for the development of medical products.

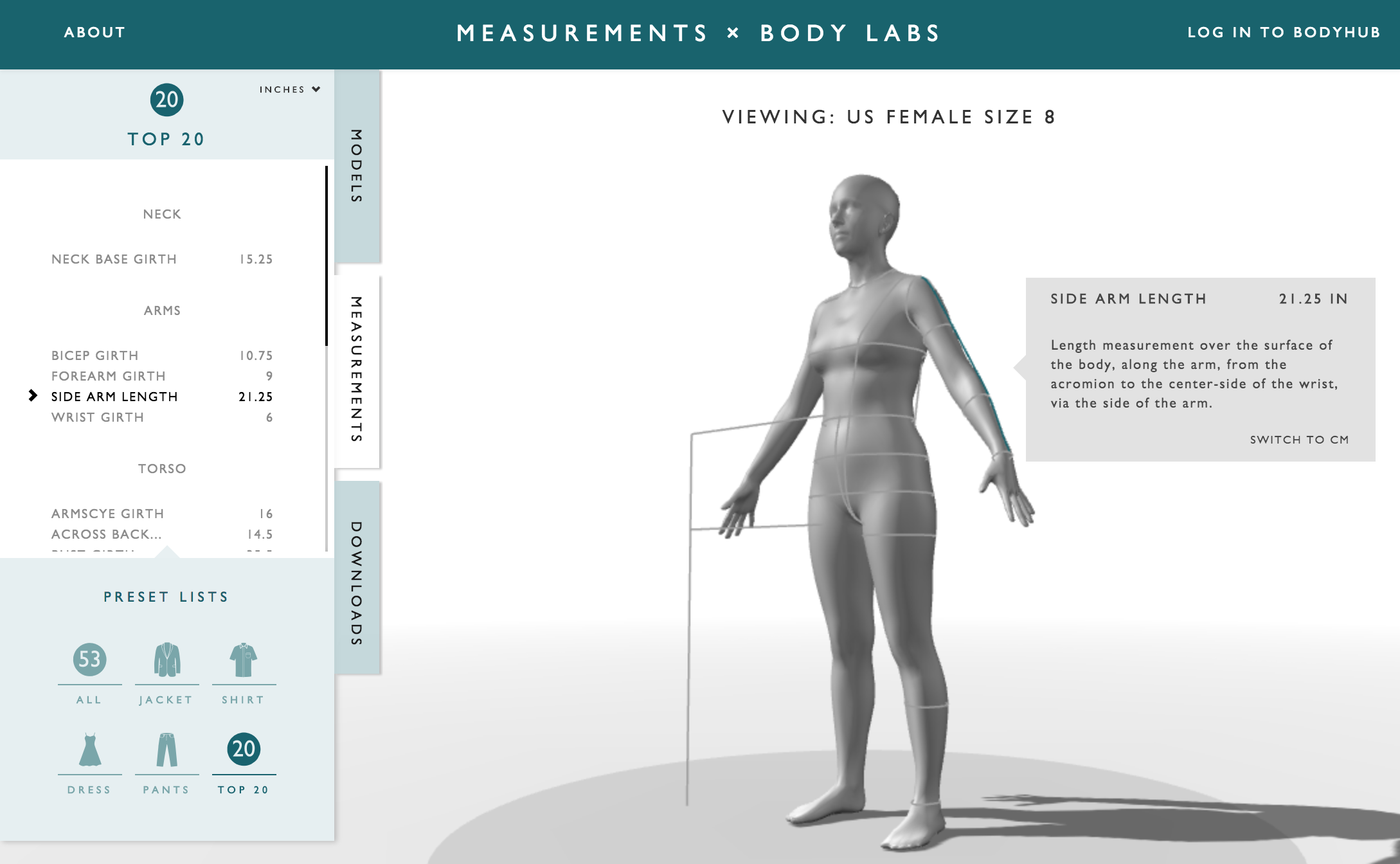

Kinect is not the only system that can be used by Body Lab. That’s because its Body Hub is a platform and a set of tools to help companies begin to interact with their customers digital selves. It is a long process moving very rapidly. “We are now releasing our SDK and API with a lot of different models to build on top on,” says Julia Gilroy, Body Labs’ director of marketing. “Although we are growing we are small and we need other people to contribute to the platform’s development by creating new apps.”

Body Labs presents its platform as the most accurate body model available, the only one that can move naturally through all its parts and not through a virtual internal skeleton. Body Labs envisions the 3D model as a digital system to customize all products. “We can extrapolate a lot of data and measurements from the body model – Julia tells me – and we can do a point to point comparison of different bodies. This means the computer knows where a specific point is on the model even if it is taking different poses. In online shopping, for example, we would not need to actually have the model wear a digital item as much as compare the data from someone of similar size and shape”.

The possibilities for this technology are endless although we are still in a very early phase and more companies need to get involved in the virtual arena to create a functional ecosystem that will lead to personalized and on-demand product manufacturing for consumers. The Body Labs technology was developed by Michael Black, a professor at Brown University who is now at the Max Planck institute in Germany, where he leads the Perceiving Systems department and is continuing his studies in the simulation of human breathing.

So far the Body Labs body models have been licensed and used by companies’ innovation departments to study and develop sportswear items made specifically to fit the particular shapes of high level athletes and – with the help of 3D printing – to produce padding for football players. To do this Body Labs uses both high end 3D scanning systems and motion capture systems. The data can then be integrated into the 3D body scan, meaning any digital body can be made to move accordingly, without each person having to go through the motion capture produce.

Julia thinks that one of the most accessible applications of Body Lab’s technology will be in the health sector. “We do body comparisons by creating a heat map and data of each part that is different between two models. This means you will be able to track and visualize how your body changes over time with exercise, which might also be convenient for buying new clothes,” Julia said.

Although it is not the only application, the virtual try-on option is the first that comes to mind. For example last year’s partnership with Nervous Systems, one of the most advanced experimental 3D printing studios, which led to the development of a 3D printed modular Kinematics Bodice.

One more possible area of application is in healthcare. Not just for the development of tailor made casts and prostheses but as a virtual application to help people overcome their own limitations in the rehabilitation process after an accident. Studies have shown that visualizing a movement can help someone replicate it successfully even if they thought they could not do it. The digital self will have to lead the way and that is exactly what Body Labs wants to have it do by making it more independent.