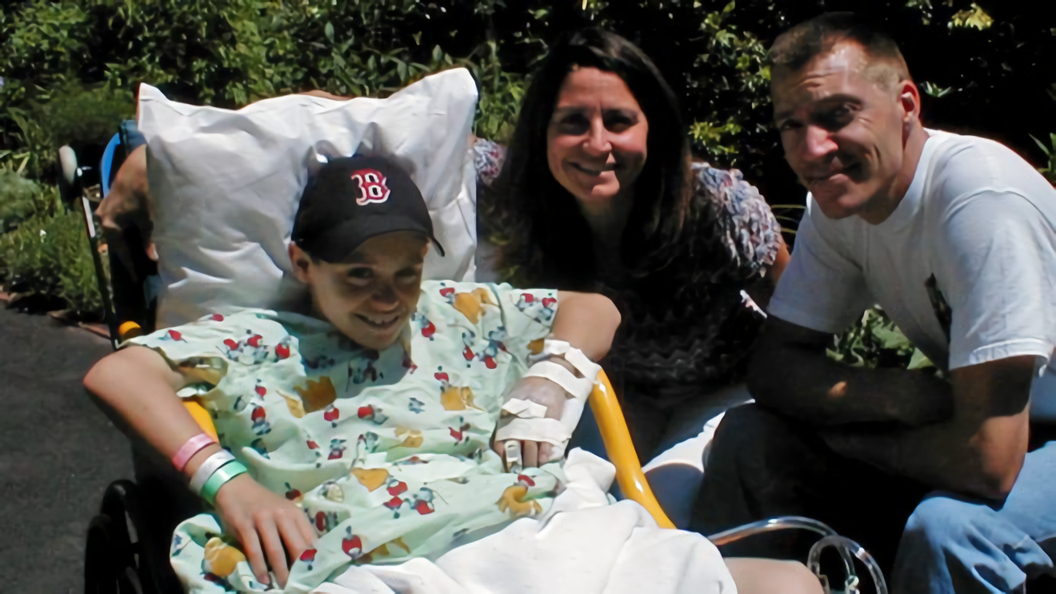

After more than a decade, a 3D bioprinted bladder, created by Dr. Anthony Atala at Boston Children’s Hospital, is sustaining the live of a patient. The 3D bioprinted organ was made to replace patient Luke Massella’s defective bladder in 2004. Since then, Massella has not required any further surgery.

Recalling the transplant to BBC News, Massella stated “It was pretty much like getting a bladder transplant, but from my own cells, so you don’t have to deal with rejection. […] I was able to live a normal life after”

3D printing a new bladder

Massella was born with spina bifida, which left a gap in his spine, and led him to undergo several surgeries at a young age. Unfortunately, a defective bladder caused his kidneys to fail, leaving him the possibility of being on dialysis for the remainder of his life. Thankfully, Dr. Atala came up with an alternative solution.

The bladder was made using a sample of Massella’ bladder tissue, and modified inkjet printer, presumably used to build a sort of scaffold/host for the cells. Incubated in lab condition, the new bladder was grown in 2 months, and then successfully transplanted into the patient.

Massella is 1 of 10 people with a bioprinted bladder grown from his own cells. According to Dr. Atala, flat structures like skin are easiest to print, whereas tubular structures like blood vessels and hollow non-tubular organs like bladders are more complex. Solid organs like hearts, lungs, and kidneys, are the most difficult to bioprint as they have more cells per centimetre, though some researchers have had small successes in this field.

Investing in bioprinted organs

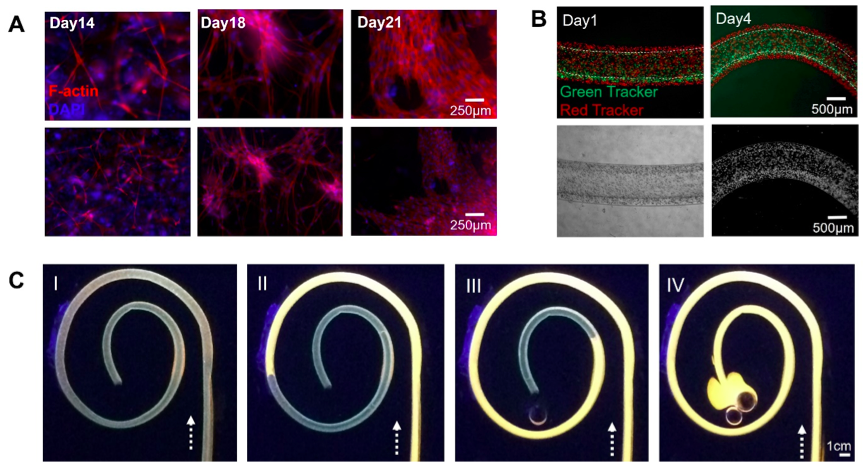

The potential of 3D bioprinted organs has led further research by many organizations around the world. Recently, a team at Indiana University School of Medicine (IUSM) were awarded $9 million to further their 3D bioprinting research for the development of transplantable organs. Leading 3D printer manufacturer 3D Systems has entered into a partnership with United Therapeutics Corporation for the purpose of 3D printing lung tissue, and BIOLIFE4D researchers at Brigham and Women’s Hospital (BWH) have successfully 3D bioprinted tubular structures which imitate the human body’s vessels.

For more 3D bioprinting partnership updates subscribe to the 3D Printing Industry newsletter, following us on Facebook and liking us on Twitter.

Seeking new professional opportunities? Search and post 3D Printing Jobs now.

Featured image shows Boston Children’s Hospital. Photo via Boston Business Journal.