BigRep, a Berlin-based manufacturer of large-format 3D printers, has announced a new partnership with engineering software developer Teton Simulation.

Together, the firms will work to integrate BigRep’s Blade slicing software with Teton’s patent-pending SmartSlice technology, a finite element method (FEM) plug-in designed to streamline build parameter optimization. By combining the former’s industrial printing capabilities with the latter’s performance requirements-based validation, the companies hope to make large-format 3D printing faster and more cost-efficient for engineering applications.

“We are excited to work with Teton Simulation and explore the possibilities of their advanced FEM technology,” said Dr. Sven Thate, Managing Director of BigRep. “We are convinced their industry-standard design verification will boost large-format FDM usage even in the most load-critical applications. We also see the possibilities of their load-based design optimization to deliver significant time and materials savings and make FDM usage on industrial level easier than ever.”

Teton Simulation’s SmartSlice plug-in

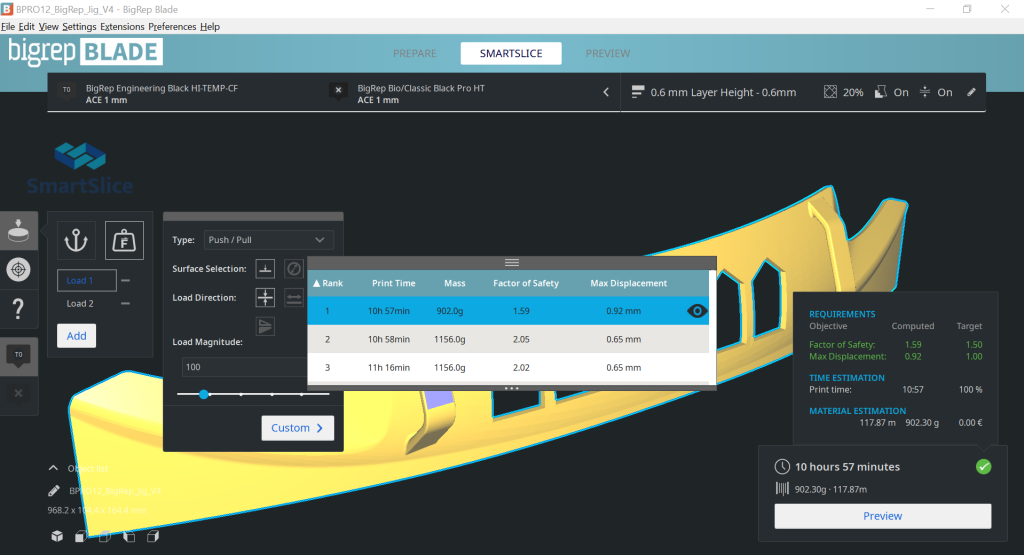

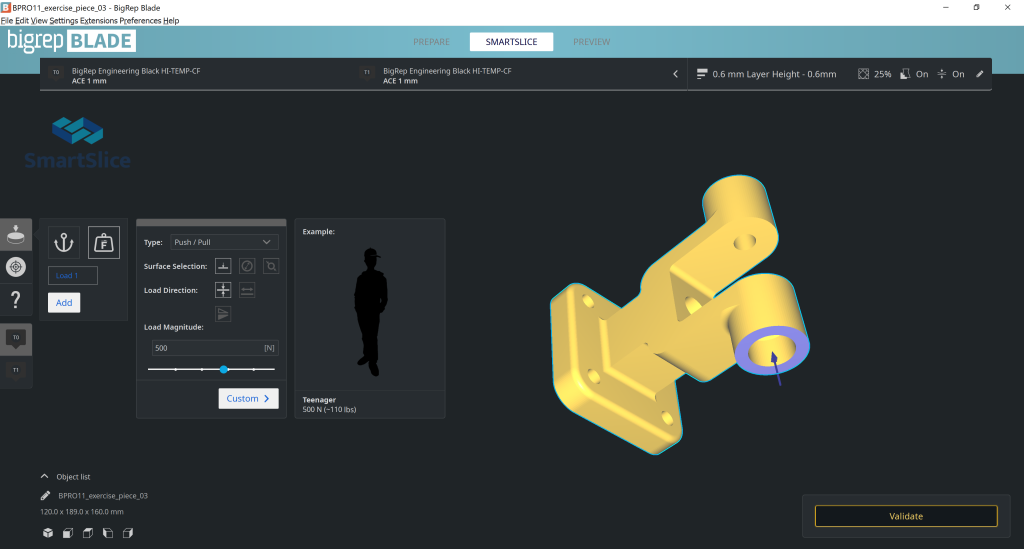

Teton Simulation claims its SmartSlice software is the industry’s first optimization technology that integrates directly with 3D printing slicers. Taking a tried-and-tested computational FEM approach, the plug-in allows users to assess the performance of parts before printing them. It’s designed to quickly and accurately define load cases for 3D printable models, while validating the end part performance against the material’s limits and expected part deflections.

Essentially, SmartSlice automatically finds the ideal slicer settings for each individual section of a 3D model. As such, it aims to eliminate the need for elaborate simulations and time-intensive prototyping, vastly reducing the cycles it takes to 3D print a high-performance part. Teton describes it as ‘taking the guesswork out of slicing parameter configuration’, enabling users to optimize build settings for better print speeds and less material usage.

The company claims its product can guarantee the expected functional load-performance of a part while ensuring a more economical 3D printing workflow.

Combining SmartSlice with BigRep 3D printing

As a modular software plug-in, SmartSlice has already been integrated with several 3D printing slicers over the past couple of years. In 2020, the technology was introduced as an update for desktop 3D printer manufacturer Ultimaker’s Essentials software platform, enabling Cura users to benefit from its functionality. More recently, the plug-in was also integrated into Stratasys’ GrabCAD Print slicer, following the expansion of the Stratasys GrabCAD Software Partner Program.

Now with BigRep’s Blade slicer also on board, large-format 3D printer users will be able to ensure their parts will meet the necessary functional and performance requirements while saving on time, costs, and filament. The integration already works with a number of BigRep-compatible materials, including PRO HT and HI-TEMP CF, and will be showcased at Formnext next week (Hall 12.1 Booth F 01).

“Teton Simulation is excited to announce our collaboration with BigRep to bring the power of SmartSlice™ to large format prints. BigRep’s ability to create high-quality, production-level parts at such a large scale provides a great opportunity to reduce material waste, increase efficiency, and save project costs,” said Doug Kenik, CEO of Teton Simulation. “And with BigRep BLADE slicer software we have the perfect vehicle to harvest the full power of SmartSlice™, bringing significant benefits to the users.”

Within the ever-growing landscape of additive manufacturing, there certainly isn’t a shortage of slicer options for add-ons like SmartSlice to enhance. 3D printer manufacturer Prusa recently launched the latest version of its open-source slicing software, the second alpha release of PrusaSlicer 2.4.0. Building on 2.4.0 alpha one, this latest release brings with it several new features and upgrades to make the pre-printing workflow faster and more efficient.

Elsewhere, Roboze, a manufacturer of high-temperature industrial-grade 3D printers, recently announced the launch of its new Prometheus slicing software at RAPID + TCT. Named after the Titan who stole fire from the Greek gods, Prometheus is designed to optimize and streamline the build preparation process for industrial metal-replacement parts 3D printed on Roboze systems.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the large-format BigRep STUDIO G2. Photo via BigRep.