Benvic, a specialist in polymer compounds, has developed a new PLA material range for 3D printing in order to support manufacturers during the COVID-19 pandemic.

The new biopolymer line of materials, known as Plantura, is suitable for compostable and durable use. Developed using Benvic’s material technology, the Plantura range also benefits from bacteriostatic properties, thus preventing bacteria proliferation.

With the new PLA material range, the company intends to lend a hand to manufacturers producing products and healthcare solutions to help support medical procedures, hospitals and health structures, which has increasingly relied on the decentralized nature of 3D printing.

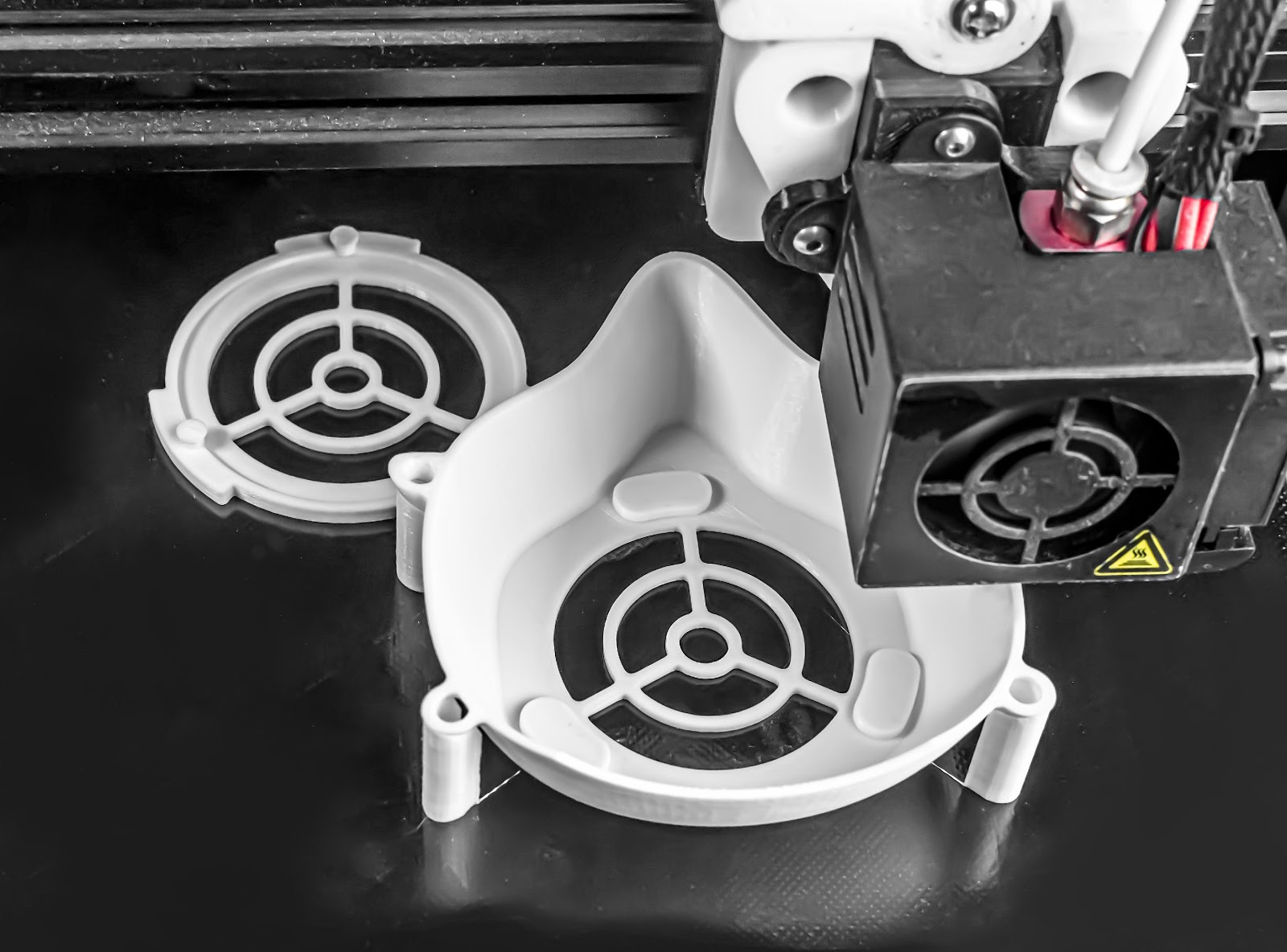

“We have developed this new material, with our filament partner, and within quite a short time for an end-customer in Italy who is print protecting masks,” explains Camilla Bortolon, account manager for Plantura product range. “Such masks are customized in line with the user morphology which is only made possible via the 3D printing process.”

“Our new materials can make these masks reusable simply by changing the filter. In this way we can optimize resources in order to fight the virus.”

Benvic’s new Plantura line of PLA polymers

Founded in 1963, Benvic’s core expertise centers on manufacturing PVC compounds for various markets, including automotive, electronics and construction. As well as PVC compounds, the company produces a range of PVC powder, thermoplastic alloys and ready-to-use stabilizers. Benvic has production facilities across Europe in France, Italy, Spain, Poland and UK.

The company’s new Plantura polymer range comes in response to the mobilization of the 3D printing community across laboratories, companies, universities and healthcare professionals to produce parts and meet unexpected demands in the wake of the pandemic.

Although additive manufacturing can be undertaken using various polymer grades, the company identified a high demand for PLA compounds for 3D printing supplies for the medical frontline, as it is a biodegradable, biocompatible, non-toxic and eco-friendly polymer.

According to the company, Benvic’s Plantura PLA range prevents bacteria proliferation on any kind of plastic surface, particularly for those who are expected to be in contact with body ski. It has been tested according to the international quality standards, ISO22196 and ISO 846. The Plantura line covers materials with different properties, from rigid to soft characteristics.

Supporting global supply chains with 3D printing

During the pandemic, 3D printing has played a key role in helping to ease the pressure on supply chains and governments. All parts of the community, from professional additive manufacturing providers and makers to designers and suppliers, have volunteered their skills and expertise in additive manufacturing to help respond to the global crisis.

An early example came out of Italy, where 3D printing was used to manufacture 100 respirator valves in 24 hours for a hospital in Brescia after it had run out.

Some have leveraged the creative freedom of 3D printing to establish inventive means of combating its spread. For example, Materialise developed a 3D printed hands-free door opener to help global containment efforts, sharing the design of the product for free.

Here at 3D Printing Industry, we have documented the 3D printing community’s response to the COVID-19 pandemic extensively, and you can view all the ways in which it has been leveraged during this crisis here.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed mask. Photo via Benvic.