Global chemical production company BASF’s 3D printing division Forward AM has set a goal to provide the most Life Cycle Assessments (LCAs) and Carbon Compensated materials within the 3D printing industry by the conclusion of 2023. The news comes as BASF renews its “commitment to sustainability.”

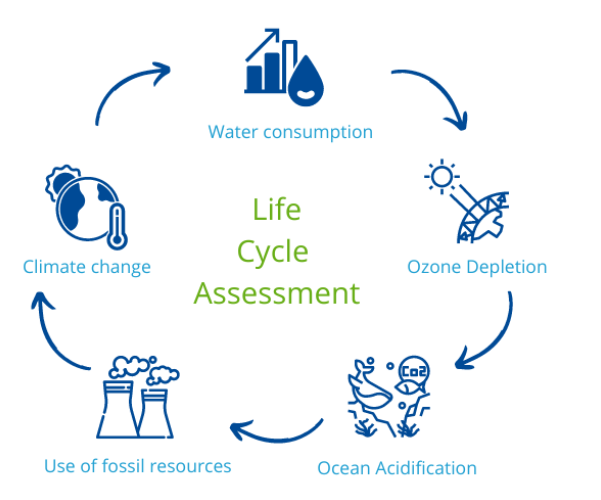

In Q4 2022, BASF Forward AM launched #ProjectZero, a long-term commitment to reducing its environmental impact. The program includes developing sustainable products, solutions, and production methods, utilizing LCAs to understand and communicate the ecological effects of 3D printing and broader industry on the planet. LCAs help measure environmental impact, allowing BASF Forward AM to reduce its carbon footprint and offset emissions through the Carbon Compensation program.

“As a global leader in advanced materials and 3D printing solutions, we recognize the importance of working towards a sustainable future for all. Forward AM is dedicated to reducing waste throughout our supply chain, minimizing our carbon footprint as well as to continue promoting social responsibility by ensuring fair labor practices and supporting local communities,” said Martin Back, CEO, and Managing Director of Forward AM. “Our innovative work and collaboration with other like-minded organizations will lead to meaningful progress towards these shared goals as the only way forward is together.”

Initiative aims to make 3D printing more sustainable

A Life Cycle Assessment is a comprehensive assessment that evaluates the environmental consequences throughout the entire production process of a product. BASF Forward AM provides LCAs for HP 3D High Reusability PP, Ultrasint PA11, TPU01, TPU 88A, and PP 1400 Black materials. Additionally, the company aims to expand this offering by including ten more LCAs by the conclusion of 2023. This total of 15 LCAs would establish BASF Forward AM as the material supplier with the highest number of LCAs within the 3D printing sector.

As a result, Forward AM will furnish a detailed analysis of the energy, material, and resource utilization throughout the entire lifecycle of a product. This information is collected from various stages of the product’s industry value chain and further consolidated into an emissions score.

BASF Forward AM has also introduced the Carbon Compensation initiative to offset its unavoidable carbon emissions and fulfill its environmental responsibility. This program serves as a practical means to promptly diminish carbon footprints while concurrently working towards renewable energy adoption and overall emission reduction. The Carbon Compensation program is available for BASF Forward AM’s PP material line, which includes HP 3D High Reusability PP, PP 1400 Black, and Ultrasint TPU01, TPU 88A, TPU 88A Black. By the end of 2023, the program will expand to include a total of 12 materials.

Can Additive Manufacturing make manufacturing more sustainable?

Recently, Dr. Phil Reeves Managing Director at Reeves Insight, gave a presentation on sustainability and 3D printing. Dr. Reeves emphasized the need to debunk myths and carefully examine the environmental impact of 3D printing. Reeves questioned the widespread claims that 3D printing is a more energy-efficient and sustainable alternative to conventional manufacturing methods. He highlighted that the energy requirements of additive manufacturing, particularly processes like Selective Laser Melting (SLM), are significantly higher than those of subtractive processes like CNC machining. The production of metal powder for 3D printing was identified as particularly energy-intensive. Reeves also discussed the importance of considering factors such as energy sources, transportation methods, and end-use applications when assessing sustainability. He concluded that while 3D printing has the potential for sustainable manufacturing, it should be approached with a “holistic, science-based perspective,” considering the entire lifecycle of the product.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows BASF Forward AM logo. Image via BASF Forward AM.