Worldwide technical standards organization ASTM International has selected three partners that it believes will help advance the current state of additive manufacturing.

Proposals from North American engineering and technology firm EWI and an Auburn University-NASA collective were selected from dozens of other applications submitted in December 2017.

Together, the partner organizations have now established Additive Manufacturing Center of Excellence, which will be located at EWI and in Auburn’s Samuel Ginn College of Engineering in Alabama.

Shaping the future of aerospace, automotive, medical and more

The Additive Manufacturing Center of Excellence will by supported by ASTM via funding, goods in-kind, and other miscellaneous services. NASA will provide specific insight into aerospace grade manufacturing at the center; Auburn will contribute its additive manufacturing research expertise to the project; and EWI will generate strategic industry consortia for further collaboration.

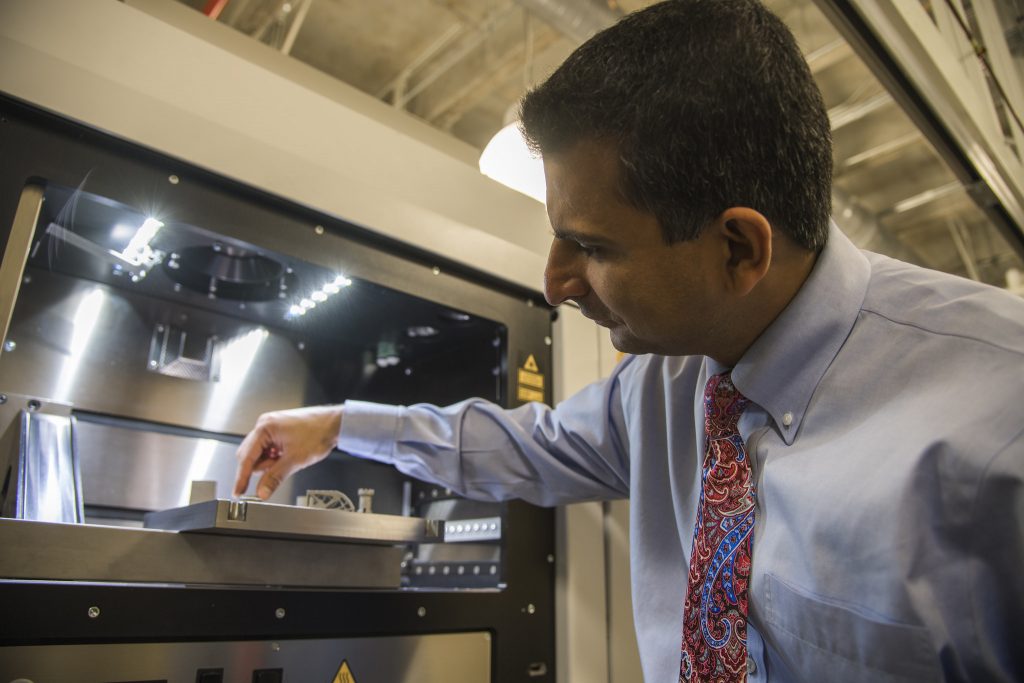

Mohsen Seifi director of global additive manufacturing programs at ASTM International is currently handling stakeholders interested in contributing to the Additive Manufacturing Center of Excellence.

According to Katharine Morgan, president of ASTM International,”This game-changing collaboration will build a strong foundation for the future of additive

manufacturing,”

“The synergy among Auburn, NASA, and EWI – combined with the trailblazing work of ASTM’s additive manufacturing committee – will help fill industry gaps and accelerate innovation,”

“It’s clear that this new center has the potential to shape the future of industries like aerospace, auto, medical, and more.”

A rocket to success, on a National scale

In addition, NASA and Auburn University are establishing a National Additive Manufacturing Center of Excellence which will complement the ASTM center.

Auburn University and NASA co-signed a Space Act Agreement “to explore and advance the applications of additive manufacturing” in August 2017.

In an extension of this relationship, the National Additive Manufacturing Center of Excellence will be spearheaded by Dr. Nima Shamsaei, associate professor of mechanical engineering at Auburn University, and Doug Wells, senior engineer of structural materials at NASA’s Marshall Space Flight Center (MSFC).

Additive projects at the MSFC include part production for the next generation Space Launch System (SLS) tipped to be the most 3D printing inclusive rocket to date.

Todd May, director of the MSFC, gives a vision of the new Center of Excellence as follows, “Additive manufacturing is a rapidly-evolving field. Advancements in this area will aid the development of more capable and lower-cost launch vehicles and spacecraft to benefit all of NASA’s science, engineering and spaceflight endeavors,”

“NASA embraces collaborations with industry and academia to advance the state-of-the-art and to help us achieve our space exploration mission goals. I applaud Auburn’s vision and focus on growing their additive manufacturing research capabilities.”

Becoming a world leader in additive

Auburn is also working with industry partners such as GE Additive, developing high-volume additive manufacturing for jet engine fuel nozzles.

In addition to R&D projects, the university will be responsible for developing comprehensive training and education resources for the newly formed centers.

Christopher B. Roberts, Auburn’s dean of engineering, concludes, “The establishment of this new center will allow us to work together to solve critical challenges in additive manufacturing that will help achieve our nation’s aerospace goals,”

“We have made major investments in faculty, laboratories and equipment to achieve a leadership position in additive manufacturing.”

For more business and education news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking to get involved in a new additive manufacturing project? Join 3D printing jobs for the latest vacancies from FATHOM, XYZPrinting and more.

Vote now in the 2018 3D Printing Industry Awards for technologies and research projects of the year. Want to design the trophy? Enter the 2018 3D Printing Industry Awards design competition. sponsored by Protolabs now.

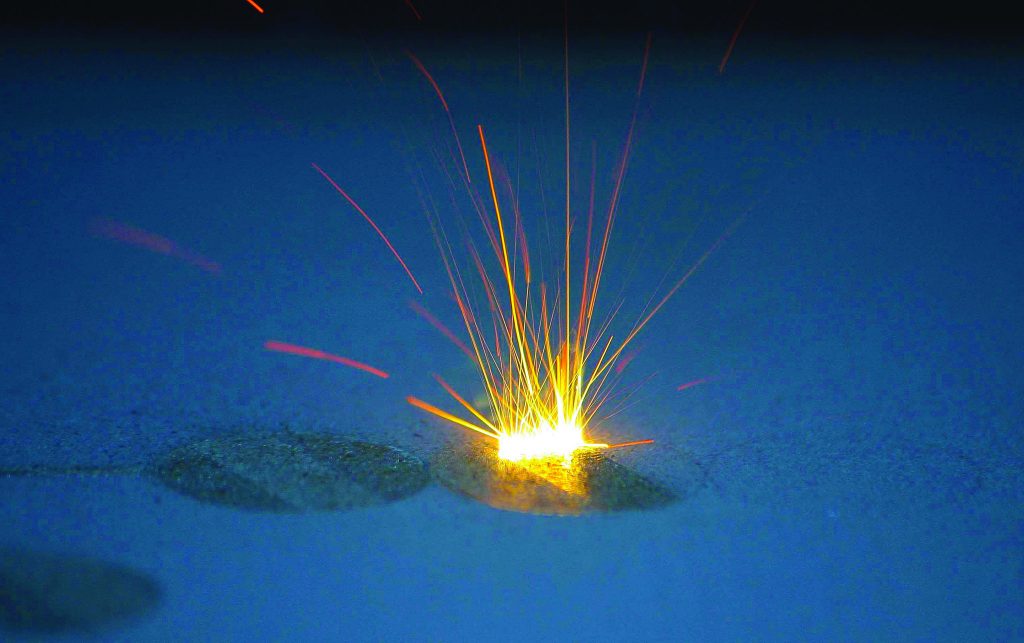

Featured image shows metal 3D printed samples at Auburn. Photo Auburn University