Additive manufacturing composites company AREVO has announced the launch of its Aqua 2 3D printer and the conclusion of a $25 million funding round.

AREVO has designed its Aqua 2 system to be a high-speed machine, with a focus on printing large-format continuous carbon fiber parts. The company unveiled its new printer after it closed a Series B funding round led by Defy Partners and GGV Capital, and supported by Khosla Ventures and Alabaster. AREVO has now raised $60 million in total, which it will use to hire new engineers and support the development of its carbon fiber 3D printing technology.

“AREVO is a compelling opportunity as it fits squarely at the intersection of GGV’s three main areas of investment focus: consumer internet, enterprise, and smart tech,” said Hans Tung, Managing Partner at GGV Capital. “AREVO is led by an experienced team with a solid technological foundation and 3D printing manufacturing know-how at scale, allowing it to offer breakthrough products at competitive prices.”

AREVO carbon fiber 3D printing technology

Established in 2014 and based in Silicon Valley, AREVO is known for its continuous carbon fiber 3D printing technology. The company began by releasing a range of FFF/FDM composites that were said to be five times stronger than titanium, and capable of reinforcing polymer 3D printed products.

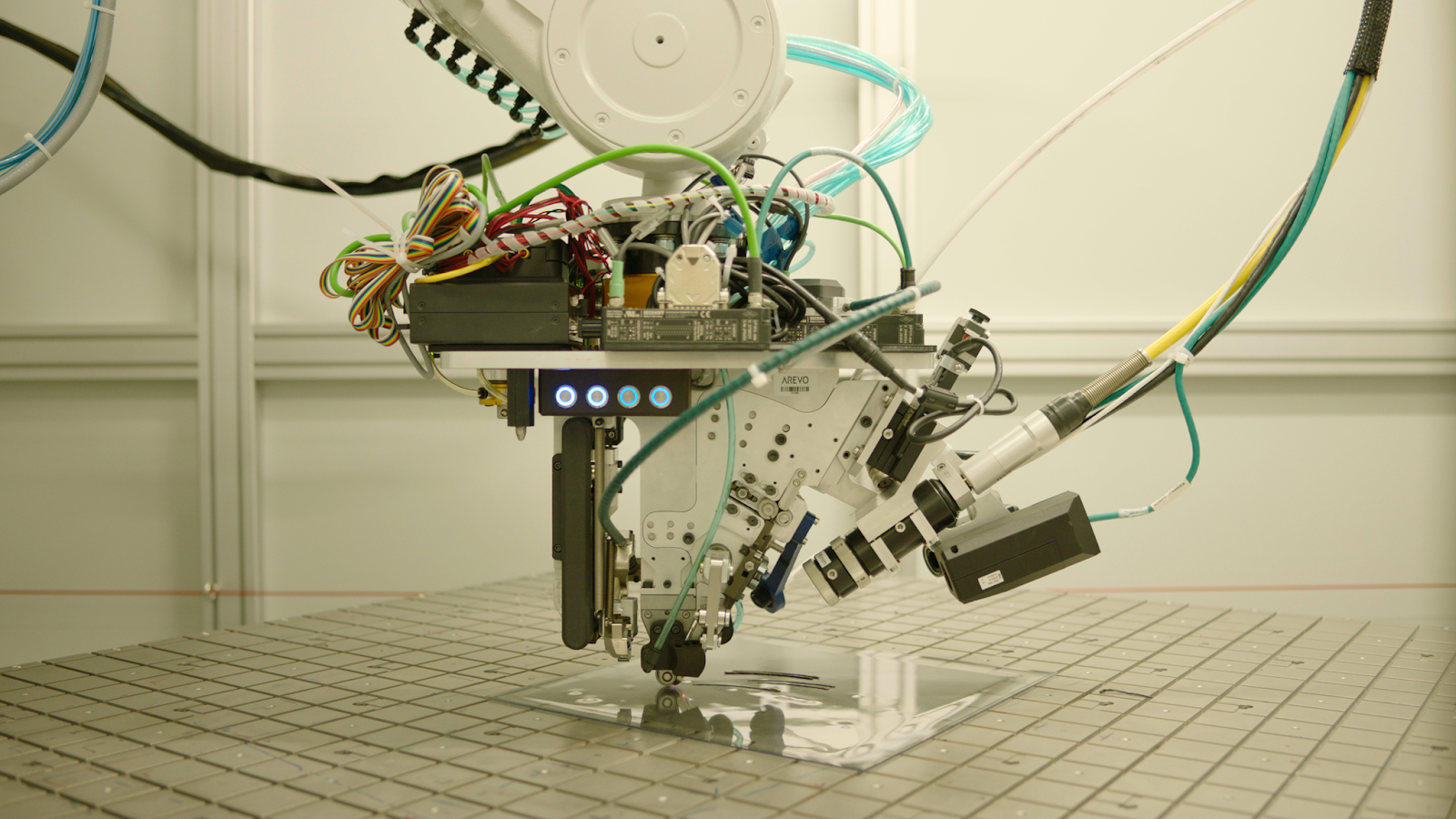

Following the successful launch of its composite materials, AREVO developed an advanced 3D printing software and systems portfolio. Based on its Finite Element Analysis toolpath optimization program, the firm created a scalable Robot-based Additive Manufacturing (RAM) platform. The system’s multi-axis toolpaths enabled it to change the orientation of extrusion, optimizing the strength and appearance of 3D printed parts.

The company has since leveraged its patented generative design techniques and RAM production platform, to 3D print bike frames with Californian manufacturer Franco Bicycles. Marketed under the Emery Bikes brand, AREVO used its DED 3D printing technology to reduce the lead times behind the bicycle’s printed parts.

AREVO has worked on a series of bike projects recently. Partnering with California-based start-up Superstrata, the company 3D printed fully-unified carbon composite frames for its upcoming e-bikes. Leveraging its continuous composite 3D printing technology, AREVO eliminated the need for glues or welding to hold the bicycles’ individual parts together. As a result, the bikes are said to be “extremely impact resistant.” The bicycle’s crowdfunding campaign hit AREVO’s initial goal of $100k in under 3 minutes, and it’s now on track to surpass $5m from over 3000 backers.

AREVO’s $60m fundraising success

AREVO has gained the backing of numerous investors as it continues to research new applications of its 3D printing technology. Khosla Ventures led the company’s initial Series A round of funding in 2016 which raised $7 million. The additional investment allowed the company to expand its operations, and begin developing strong, lightweight parts for use in production applications.

Japanese glass company Asahi Glass later led AREVO’s initial Series B round of funding, raising $12.5 million. Sumitomo Corporation of Americas, Leslie Ventures and Khosla Ventures also supported the investment. AREVO used the extra funding to continue developing its multi-axis RAM platform, which it now refers to as “True 3D Printing Technology.”

After a series of investments, AREVO has raised a combined $60 million of investment. The company recently deployed its Aqua 2 3D printers in the production of the Superstrata e-bike, and the funds will be used to boost the system’s development. AREVO’s Aqua 2 has been specifically designed to produce large-format continuous carbon fiber parts, and is reportedly capable of printing up to one cubic meter in size. The firm’s newest system is also able to print four times faster than its predecessor, enabling it to rapidly create on-demand custom parts.

“AREVO’s new platform enables the fabrication of high strength, low weight carbon fiber parts, currently not possible with today’s standard techniques,” said Trae Vassallo, Founding Partner at Defy. “We are thrilled to be working with the team to help scale up this incredibly impactful technology.”

As part of the latest financing arrangement, investors Defy have appointed Brian Shin, a serial entrepreneur, investor, and Defy Scout, to join Arevo’s board. “We are excited to have Defy and GGV Capital on board to bring not only capital but a vast amount of strategic experience,” said Hemant Bheda Co-founder and Chairman of AREVO. “The strong interests in the company despite tough market conditions really reaffirm our vision.”

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the print head of AREVO’s new Aqua 2 3D printer. Photo via AREVO.