Arevo Labs came out of the woodwork of the Silicon Valley last March with a range of industrial composites for fused filament 3D printing. Some of the materials, like ULTEM, are exclusively Stratasys filaments and their portfolio also contains PEEK, PPSU, and SRP. Since then, Arevo Labs has been expanding their product line to include advanced 3D printing software, which includes Finite Element Analysis, meant to predict mechanical and thermal performance in order to generate the optimal toolpath for a 3D printer. They’ve taken this technology one step further, creating a scalable “Robot-based Additive Manufacturing (RAM) platform” for 3D printing industrial-quality, composite parts from just about any angle.

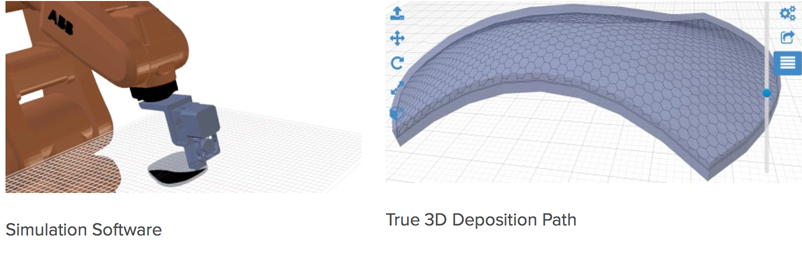

The RAM platform is made up of a commercially available robot, a composite deposition extruder, and Arevo’s software suite. The platform is meant to work on a six-axis robot and, with the thermal management system and deposition head, is able to 3D print with multi-axis toolpaths in order to change the orientation of extrusion for the best strength and appearance of a part. Because the process has been optimized for ABB line of robots, Arevo states that RAM 3D printing can be scaled from the smallest IRB 120 robot all the way up to their larger machines. This means that they can expand from the IRB 120’s 1000 cubic mm build volume up to an 8 cubic meter build volume.

Necessary to the operation of the RAM system is Arevo’s software suite, which allows for converting CAD models into 3D printing toolpath capable of six degrees of freedom. Arevo also states that the software uses a “precise kinematics simulator” to validate and optimize a part for 3D printing. Finally, the platform integrates with ABB’s RobotStudio programming and simulation software.

A number of companies and research institutions are working on a commercial 3D printer capable of six-axis 3D printing, but I believe that the RAM platform from Arevo Labs is now available on the market. We’ve also seen an increase in the use of robotic arms for 3D printing with everyone from art and design studios taking advantage of the freedom offered by these machines to small startups, like Branch Technology and MX3D, using large industrial robotic arms to fabricate large-scale structures. I may be wrong, but this may be the first commercial partnership seeing this technology brought to the market. And the fact that the RAM system can use industrial composites makes this a particularly interesting development. Should the official makers of ULTEM be worried?