AREVO, a Silicon Valley company dedicated to direct digital additive manufacturing of composite materials, has worked with new California-based start-up Superstrata to 3D print the fully-unified carbon composite frames for its upcoming e-bikes.

By producing the frame in a single piece using AREVO’s continuous carbon fibre 3D printing technology, Superstrata has eliminated the need for glues or welding to hold its individual components together. This makes the bike frame “extremely impact-resistant,” and constructing the bikes using carbon fiber reinforced thermoplastics has allowed them to be lightweight, reportedly weighing less than 1.3kg or two bottles of water.

With the companies’ ‘Terra’ and ‘Ion’ 3D printed bikes now being made available for pre-order, Sky Christopherson, two-time former Olympian cyclist and world record holder for the velodrome sprint, has thrown his weight behind the new bicycles. “My Olympic race bikes were light, but would crack when pushed too hard or crashed. Having a bike that’s light like other carbon fiber bikes but really tough is a dream come true.”

AREVO’s 3D bike printing credentials

Founded in 2014, AREVO began by launching a range of carbon fiber and carbon nanotube materials for the purposes of composite reinforcement. These nanotubes, which were reportedly stronger than steel, could be used to reinforce objects made with AREVO’s 3D range of plastics, and might be seen as a precursor to the company’s segway into bike production.

AREVO later raised $7million in a Series A funding round led by venture capital firm Khosla Ventures. This allowed the materials company to expand its operations, and begin developing strong and lightweight composite parts for use in production applications. Having raised a further $12.5m in Series B funding led by glass manufacturing company Asahi Glass, AREVO’s initial plans to 3D print bicycles, began to peddle a little faster.

Using its patented generative design techniques, and proprietary multi-axis robotic additive manufacturing platform, the company then started 3D printing bike frames for Californian bike manufacturer Franco Bicycles. Marketed under the Emery Bikes brand, the unibody carbon fiber frames were manufactured using AREVO’s Direct Energy Deposition (DED) 3D printing technology, and later integrated into the company’s Emery ONE eBike range.

As a result, while Superstrata claims that its collaboration with AREVO represents the “world’s first” custom 3D printed unibody bike, the company already has a long history of utilizing 3D printing within similar applications.

Superstrata’s ‘Ion’ and ‘Terra’ 3D printed bikes

While other businesses, such as German bicycle manufacturer Urwahn Bikes, have also successfully 3D printed bike frames, they have often been produced in pieces, before being soldered or welded together. Superstrata’s new e-bikes on the other hand, are manufactured in one single piece, providing their frames with seamless strength and impact resistance qualities. “This bike was designed to leverage all the benefits of this new manufacturing technology to get the best of both worlds: strength and lightness,” summarized Bill Stephens, the creative force behind the bicycles.

Utilizing AREVO’s DED 3D printing process has also allowed for a significant deal of customization on the bikes. Each frame is able to be individually crafted based on 18 precise measurements, ensuring a custom fit for riders from 4’7” to 7’4”. Moreover, if you include a range of additional adjustable settings such as ride position and stiffness level, the bike has over 500,000 potential combinations, according to Superstrata.

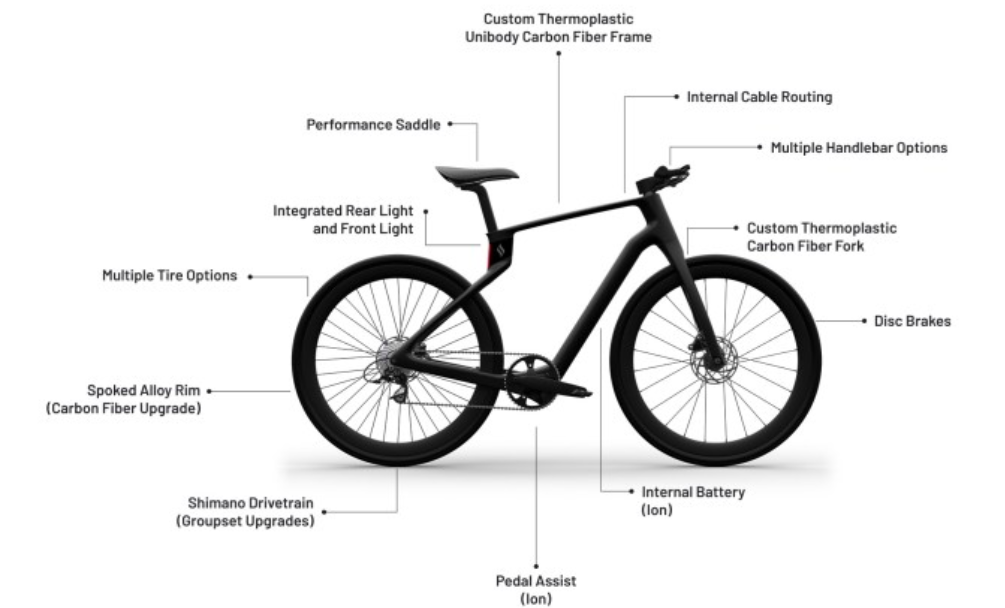

Two versions of the bicycle will be made available later this year, the Terra which will retail for $2,799, and the Ion E-Bicycle for $3,999. The latter features a battery which can be fully charged in two hours, providing for up to a 55-mile range, while both bikes have integrated data and power wiring throughout their frames, enabling a variety of electronic upgrades. These include customization to accommodate different riding styles (racing, street, gravel, or touring), wheel materials (metal or carbon fiber), or colorways (light or dark).

Following a successful kickstarter campaign run by AREVO CEO Sonny Vu, which has seen the company raise more than £800,000, Superstrata is now accepting pre-orders for its 3D printed e-bikes. Customers who want to pre-purchase the bicycles or one of their accessories, can do so here. Both iterations of the bike are currently scheduled for release in December 2020.

Additive innovation in bicycle production

AREVO isn’t the first company to use additive manufacturing within bicycle manufacturing, and many other companies have also 3D printed improved bike frames.

Metal 3D printer manufacturer Renishaw for instance, worked with British automotive firm Lotus, and bicycle engineering company Hope Technology, to design a new track bike for the Great Britain Cycling Team last year. Using the company’s RenAM 500M system, designers prototyped and produced end-use parts for the bicycle to deliver improved track performance.

Similarly, Amsterdam-based Robotic Additive Manufacturing (RAM) technology developer MX3D released an updated take on its 3D printed bike in September 2019. Named the “Arc Bike II”, it was 3D printed from aluminum using Wire Arc Additive Manufacturing (WAAM) technology.

Quirk Cycles, a bespoke bicycle framebuilding company, also showcased an enhanced 3D printed bike frame design at the Bespoked UK Handmade Bicycle Show last year. Utilizing 3D metal printing, the company created a stainless steel bolt and clamp system for the bike’s seatpost, yielding a seamless metal design in the process.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the upcoming Superstrata bike, which is produced using AREVO’s 3D printing technology. Image via Superstrata.