Netherlands-based 3D printer manufacturer Admatec has introduced a new DLP 3D printer: the Admaflex 300.

An open, modular system, the standard Admaflex 300 3D printer is compatible with ceramic materials, though it also allows customers to expand the system with an optional module enabling metal 3D printing.

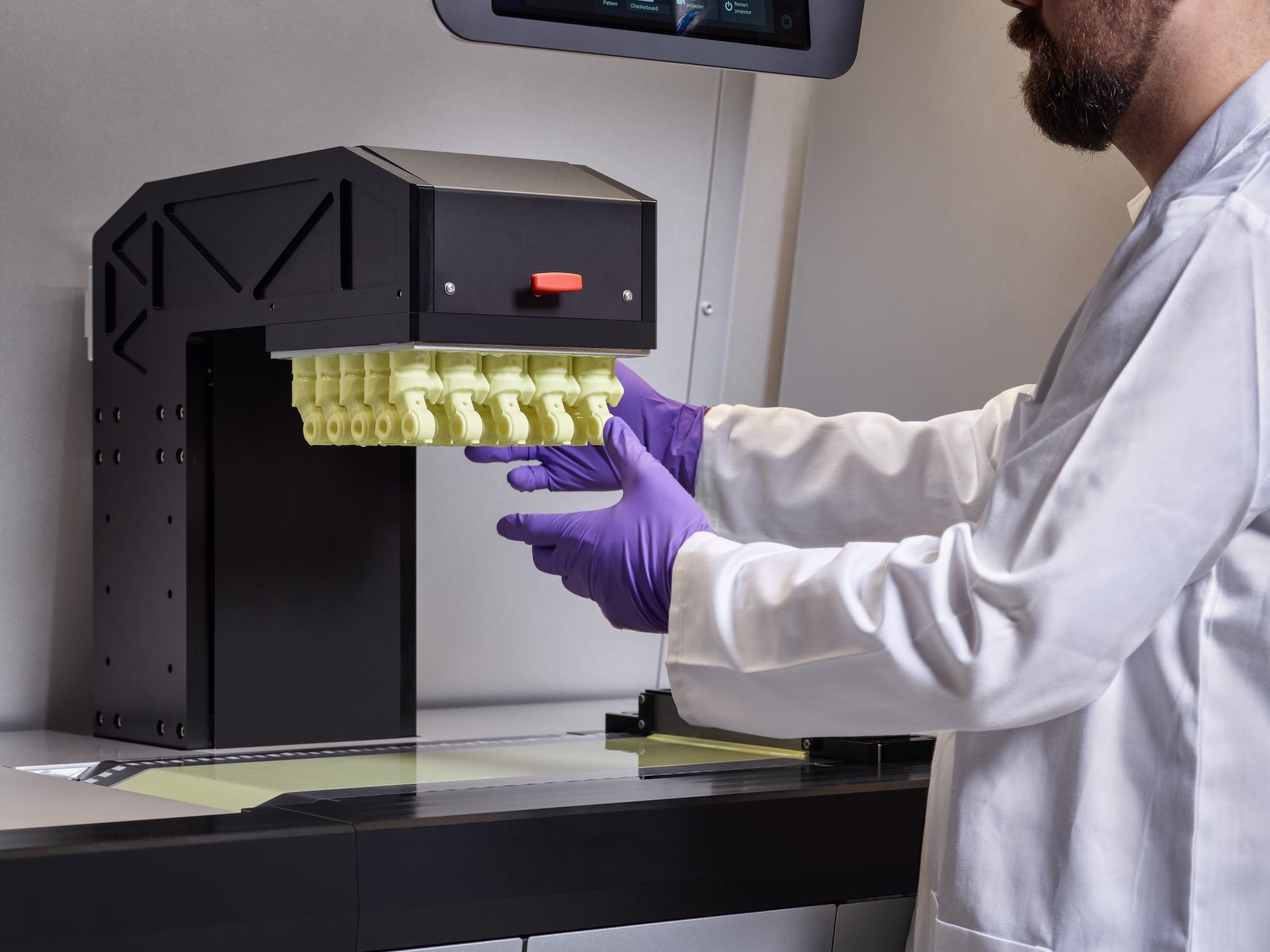

Admatec has designed the system to fulfill the need for producing large-scale alumina parts, silica cores and shells, meeting the demands of customers in the investment casting industry. As a result, the company has increased the build size of the Admaflex 300, compared to its previous system, the Admaflex 130.

Jaco Saurwalt, COO at Admatec, commments:

“Our customers’ feedback led to the development of an increased build platform size, enabling the investment casting industry, among others, to expand their ceramic 3D printing capabilities.”

The Admaflex 300

Admatec’s first machine, the Admaflex 130, was released by the company three years ago in September 2016. It was initially designed to 3D print accurate and fine featured ceramic parts using the DLP 3D printing process. Following this, the company developed an optional add-on for the Admaflex 130 that allows it to 3D print in metal as well.

The Admaflex 300 upgrades the formula used in the previous system with an increased build volume at 200 x 200 x 300 mm, compared to the Admaflex 130’s 90 x 56 x 110 mm. Featuring a modular design, it is also compatible with Admatec’s metal add-on for metal DLP 3D printing.

The modular concept also opens up the possibility for users to develop their own materials, setup a customized 3D printing process and maintain total control over the system. This will also help the machine to accommodate all future developments made by Admatec, such as multi-material printing. The company’s customized approach is a response to the widening applications for ceramic additive manufacturing from R&D to production purposes.

Admatec’s new machine is equipped with a patented automated feedstock system enabling continuous throughput for high volume production. It is designed to handle materials with high viscosity, typically associated with ceramic slurries. The system also utilizes an automatic vision controlled dosing mechanism to enable the 3D printing of large components.

Another key feature of the Admaflex 300 3D printer is its integrated in-process quality monitoring system, which was initially released by Admatec as an add-on for the Admaflex 130 earlier in 2019. It enables full traceability of the 3D printing process, allowing users to monitor temperature, humidity and foil usage, as well as observe the print job in real-time, layer-by-layer. This is done through a multitude of hardware and software components including a dual-camera system and integrated sensors. Users are also able to stop a print job after detecting a defect.

Technical specifications

| Technology | DLP |

| Printing build volume (X,Y,Z) | 200 x 200 x 300 mm | 7.87 x 7.87 x 11.81 inch (80 μm) 200 x 160 x 300 mm | 7.87 x 6.30 x 11.81 inch (62.5 μm) 160 x 128 x 300 mm | 6.30 x 5.04 x 11.81 inch (50 μm) 100 x 89 x 300 mm | 3.94 x 3.50 x 11.81 inch (35 μm) *Optional increase of Z stage, up to 500 mm | 19.69 inch |

| Layer thickness | 10 – 200 µm |

| Build speed | Up to 300 layers per hour |

| Machine dimension (WxHxD) | 1282 x 1900 x 1000 mm | 50.47 x 74.80 x 39.37 inch |

| Weight | ca. 500 kg | 1100 lbs |

| Required working temperature | 22 +/- 2°C |

| Required working humidity | < 40% |

| Connectivity | Ethernet, USB |

| Power requirements | 110 / 230 V |

| File compatibility | SLC, STL |

| Final product density | Technical ceramics > 98.5% – 99.8%* Metals > 99%* *depending on sintering curve |

The Admaflex 300 will be available for pre-order from 19 November, where it will also be showcased at Formnext 2019 in Frankfurt. You can find Admatec at the show in Hall 11, Booth A29.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The Admaflex 300. Photo via Admatec.