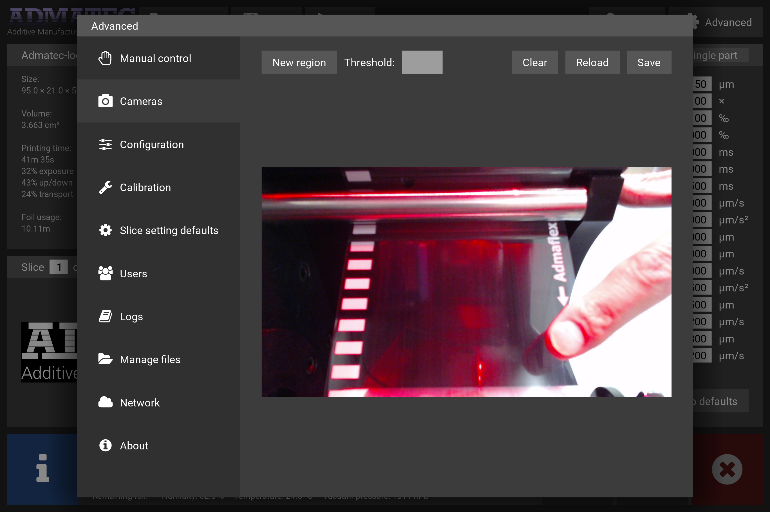

Netherlands-based 3D printer manufacturer Admatec has announced the launch of a process monitoring system for its Admaflex 130 3D printer. Available as an add-on to the company’s modular ceramic and metal 3D printer, the new vision-based monitoring system is designed to provide full documentation and traceability of the production process during printing.

Admatec has introduced the process monitoring system in order to optimize print quality, as it provides users with the choice to alter print parameters in the event of a failure. The company considers the add-on particularly useful for customers in the biomedical and aerospace sectors where print quality is significant for safety compliance. Admatec also plans to integrate the monitoring system as a standard feature in its new to launch printer in the pipeline.

Speaking with the company, 3D Printing Industry learned more about the process monitoring system and the advantages it provides. Jaco Saurwalt, COO at Admatec, states the following: “We are constantly working to improve not only with new hardware and material development but also in functionality and productivity.”

“Our customers are now able to trace back each step of the print with additional log files that work as proof of the AM process particularly needed for biomedical and aerospace applications.”

Providing evidence of 3D printing failures

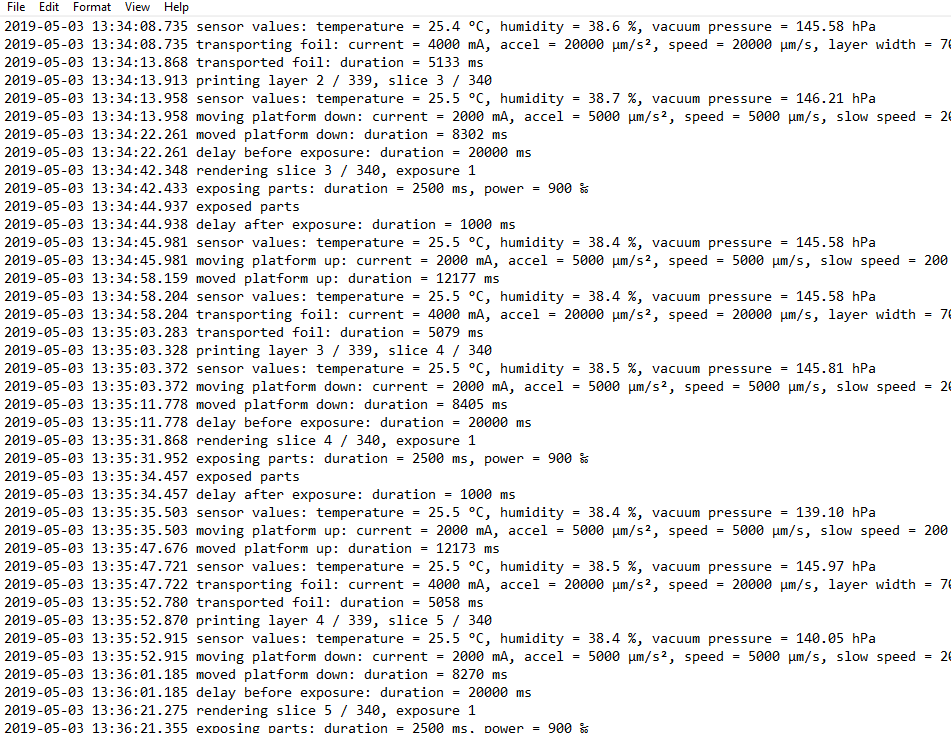

The technologies that comprise Admatec’s new vision-based process monitoring system includes a camera and a temperature and humidity sensor and offers users increased control over the Admaflex 130. Users are able to observe and record everything that occurs during the 3D printing process, as it provides layer detection, foil movement, time-lapse videos, and log files. Layer-by-layer monitoring means the system is able to detect failures in a single print and report them to the user without halting the entire 3D print job.

The data collected by the monitoring system acts as proof for the success or failure of each layer in a 3D print, according to Admatec: “We monitor in real-life the photopolymerization of each layer, providing proof for every single layer that has been printed successfully. In the log file, we have all slicing instructions of each layer of the print including environmental conditions of the printer like temperature and humidity.”

Admatec explains that the monitoring system has been designed to automatically detect failures, where users will then receive a warning via their computer, or on the UI display of the Admaflex 3D printer. Users will also gain access to a time lapse of the 3D print allowing them to observe each printed layer as evidence of the parts that failed to 3D print, against those that were successful. Explaining how this will benefit the user, Admatec comments “The user is now able to act and do something in order to recover a print failure, instead of starting again from the start. This will save time, and cost of material. Moreover, this will give more room for errors, because we believe that great innovation comes from great failure. Our machines are widely used in research and development, where they have to continuously experiment.”

“The user will be able to get, automatically, proof of evidence for print success or failure, by being able to look back at the time lapse of the printing process.”

Widening applications for ceramic additive manufacturing

The Admaflex 130 is a DLP 3D printer released by Admatec in September 2016, initially designed to 3D print accurate and fine featured ceramic parts, using the company’s patented ADMAFLEX 3D printing process. Admatec has also developed an optional add-on for the Admaflex 130 that allows it to 3D print in metal as well. Compatible materials for the system, therefore, include aluminum oxide, zirconium oxide and silicon oxide, as well as the 316L, 17-4-PH and Inconel 625 metals.

Admatec state that, since its commercial launch, many Admaflex 130 3D printers have been installed worldwide, which has allowed the company to receive valuable customer feedback on how to improve the system. Launching the process monitoring system is a response to significant customer demand for evidence of print quality, according to the company. “From our job-shop experience, we learned that it is very helpful to change printing parameters during a print, in order to optimize print quality, especially when experimenting with new materials or geometries.”

“Furthermore we have a strong demand for evidence of print quality, due to an increase of use of our 3D printers in a production environment. For ceramic 3D printing is particularly important to have a proof of every layer printed successfully as missing material can be the cause of cracks in the final fully dense component.”

Admatec’s new process monitoring system is one of many options that users can choose to integrate within their Admaflex 130 3D printer. Customers are also able to tailor the system’s features according to their own purposes, with customizable options for the build plate size, pixel size of the projector, printing speed and more. The company’s ‘customized approach’ is a response to the widening applications for ceramic additive manufacturing from R&D to production purposes. “We are witnessing a gradual change in ceramic AM, from being used mostly as a research and development tool to an actual production method, especially for investment casting and aesthetic applications,” explains Nadia Yaakoubi, business developer at Admatec.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Admatec’s Admaflex 130 3D Printer. Image via Admatec.