There’s a lot of necessary parts that go into the production of a camera; the sensors, light sources, actuators, lenses, and other optical attachments are all needed to achieve the aimed functionality of each particular camera. But what if the production process behind the camera was simplified into Lego-like building blocks, allowing the ability to constantly reconfigure the functionality of the camera by adding and subtracting these various components. With the help of 3D printing technology, that’s exactly what Columbia Engineering’s Computer Science Professor Shree Nayar and Ricoh Corporation scientist Makoto Odamaki have joined together to do. Their DIY modular imaging system is called Cambits, which is composed of five different camera components, each of which is embedded into a 3D printed building block and connectable with one another.

Each 3D printed block is easily configurable, physically connecting through magnets and electrically connecting by spring-loaded pins, which carry the power source, data, and control signals throughout each block. Within each Cambit block is a circuit board that was designed by Odamaki, including a microcontroller, an upstream interface, and a downstream interface, allowing control signals to travel in both directions.

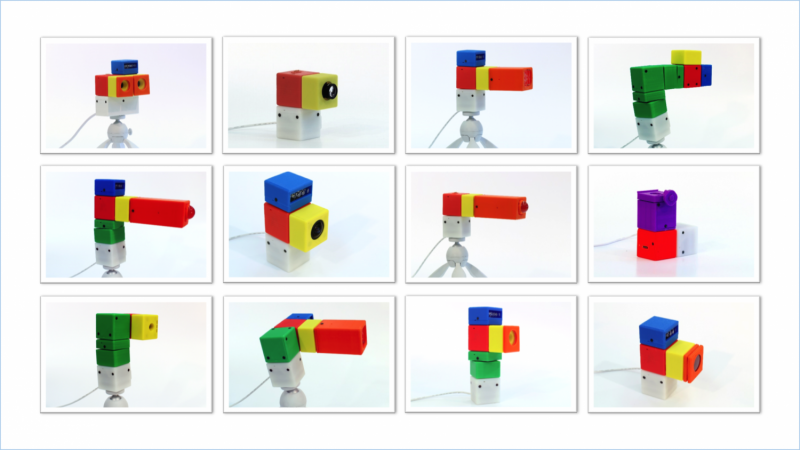

The computational photography algorithms that are used within the Cambit blocks were developed by Columbia Engineering Master of Science students. Each Cambit block is a different color, which represents a different function, there’s white for the camera base, red for sensors, blue for flash, green for actuators, yellow for lenses, and orange/purple for optical attachments. Through a number of possible reconfigurations, Cambit users can achieve a variety of different functions, including high dynamic range imaging, panoramic imaging, refocusing, light field imaging, depth imaging using stereo, kaleidoscopic imaging and even microscopy.

“Traditional cameras are really like black boxes that take one type of image,” said Dr. Nayar. “We wanted to rethink the instrument, to come up with a hardware and software system that is modular, reconfigurable, and able to capture all kinds of images. We see Cambits as a wonderful way to unleash the creativity in all of us.”

The concept took Odamaki and Nayar two years to actualize, and they hope to further partner with a manufacturer to bring their Cambits to the consumer market. 3D printing technology has been of major interest for Odamaki and the Ricoh Corporation, who even manufactured their own industrial-grade SLS 3D printer late last year. So, to me at least, it isn’t a big surprise that a project involving one of their scientists is dependent on 3D printing technology to help house the camera components. Though their report on the Cambits doesn’t delve into the 3D printing process too much, I think it’s safe to assume that the technology was an efficient way to create custom prototype components for a potentially mass manufactured product.

“There are so many exciting advances in computational photography these days,” Dr. Nayar adds. “We hope this reconfigurable system will open the door to new avenues of creativity, bringing new dimensions to an art form we all enjoy.”