3devo, a Netherlands-based manufacturer of material processing systems for the 3D printing industry, has launched its new GP20 Shredder Hybrid for recycling 3D printed plastics.

The 2-in-1 modular system is both a shredder and a granulator, and works with most commercially available polymer materials. According to 3devo, the new GP20 has been optimized for cleanability and throughput, granting precise thermoplastic regrinds in a fraction of the time of its predecessors. The system’s Smart settings also enable close control of cutting speeds, particle sizes, and material feed input depending on the material type and application.

Timo Van der Laak, 3devo’s Material Specialist, explains, “Similar to most of our clients, we work with various polymers, so the flexibility of materials that the GP20 can shred is beneficial. But with the multiple polymers that we shred, it’s crucial that we can clean the machine thoroughly to prevent contamination in our experiments.”

Flexible material recycling with 3devo

Founded in 2016, 3devo offers a number of material processing systems that enable desktop recycling for 3D printed materials. The company’s product range covers everything from shredding and granulation to end-use filament extrusion, all under one environmentally-friendly banner.

The original SHR3D IT system is capable of granulating up to 5kg of material per hour. The granules can either be used with pelletized feedstock 3D printers or extruded into a wire filament using one of the company’s dedicated desktop extruders – the Composer and Precision series filament makers.

More recently, 3devo even launched an upgraded purging material for its machines called DevoClean Midtemp EZ. The compound allows users to more effectively clean their filament makers between jobs, preventing cross-contamination and ensuring system durability.

The GP20 Shredder Hybrid

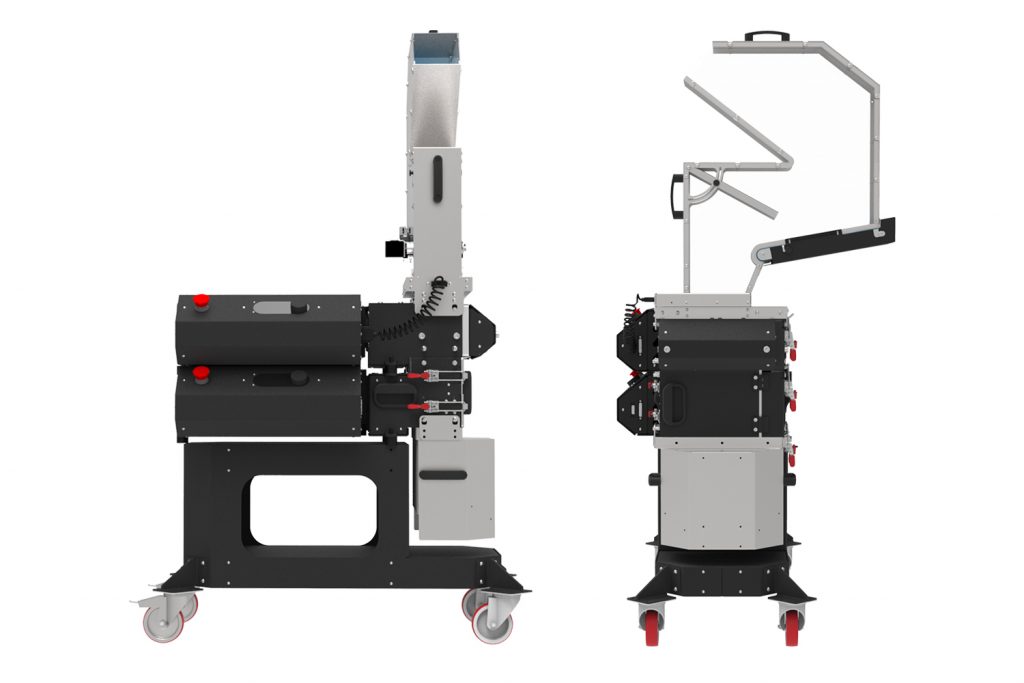

As the latest addition to the portfolio, the GP20 is intended to bridge the gap between R&D and small-scale production. While most 3D printing manufacturers tend to opt for a third-party for their material recycling needs, those using a GP20 will be able to bring the entire workflow in-house (with a footprint of just 950 x 750mm).

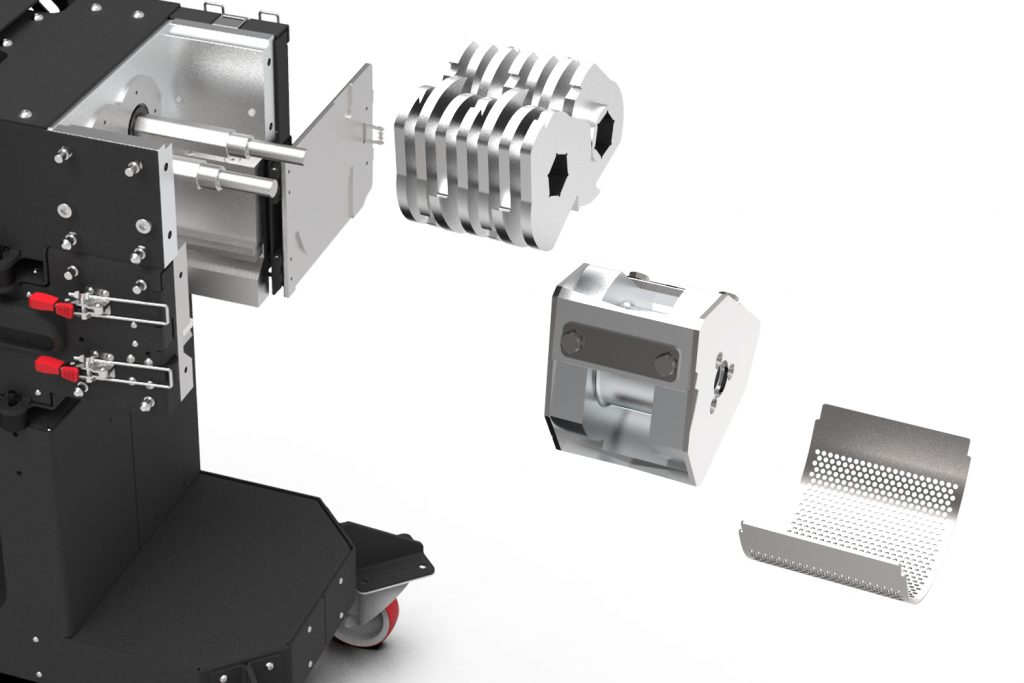

Equipped with 14 shredding blades by default, the system is able to shred everything from purgings and plastic bags to film and plastic bottles. Users will also be able to recycle glass fiber-reinforced composites, carbon fiber-reinforced composites, a variety of 3D prints, and injection molded parts.

Since the GP20 is largely modular in design, many of the individual components can be switched out to better address a customer’s needs. This includes the shredder blades (combinations of two, three, and seven teeth blades are available) and the filter screen. A new hopper design also means users are better protected from accidental contact with any moving internal components. All of the necessary components have also been designed to be accessible and removable, making maintenance all the more streamlined.

Mike Reinalda, 3devo’s Mechanical Engineer, adds, “We listened to the feedback our customers came with from our previous shredder. Safety has always been our top priority. So next to the new hopper design, which prevents any direct access to harmful components, we included smart sensors throughout, which ensures that the machine doesn’t start shredding until all the safety requirements are met.”

Technical specifications and pricing

Below are the technical specifications for the GP20 Shredder Hybrid. The system, along with the rest of the GP20 series, is available to pre-order now. Visit the 3devo store page for a quote.

| Default filter screen | 3.5mm |

| Total shredding blades | 14 |

| Voltage | 120V; 240V |

| Dimensions | 950 x 750 x 1450mm |

| Hopper opening | 120 x 144mm |

| Weight | 125kg |

Nominations for the 2021 3D Printing Industry Awards are now open, have your say who is leading the industry now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the GP20 2-in-1 shredder and granulator. Photo via 3devo.