Leading 3D printer manufacturer 3D Systems has taken another step forward in its medical portfolio through a partnership with non-profit organization OpHeart.

Based in Houston, Texas, OpHeart integrates additive manufacturing technologies to provide children born with life-threatening heart defects with the best medical treatment available. As part of this initiative, the company also operates a “Heart-in-Hand Pledge”, granting any requesting doctor or parent with a 3D printed model of their Coronary heart disease (CHD) patient’s heart before surgery, regardless of the family’s or hospital’s ability to pay. In this collaboration, 3D Systems is participating in OpHeart’s “Heart-in-Hand Pledge.”

Anne Garcia, Co-Founder and Executive Director, OpHeart stated:

“It is our hope that as more surgical teams work with OpHeart to employ 3D Systems’ anatomical models in their CHD surgeries, we will be able to definitively demonstrate what is common sense – providing doctors the ability to better prepare for complex surgeries makes a meaningful, measurable difference in the lives of these children.”

3D printed anatomical models

The American Heart Association recognizes CHD as the most common birth defect within the U.S. As a result of CHD, over 100,000 babies are in need of high-risk surgeries in order to survive.

After her own daughter was born with a life-threatening heart defect, Garcia co-founded OpHeart in 2015.

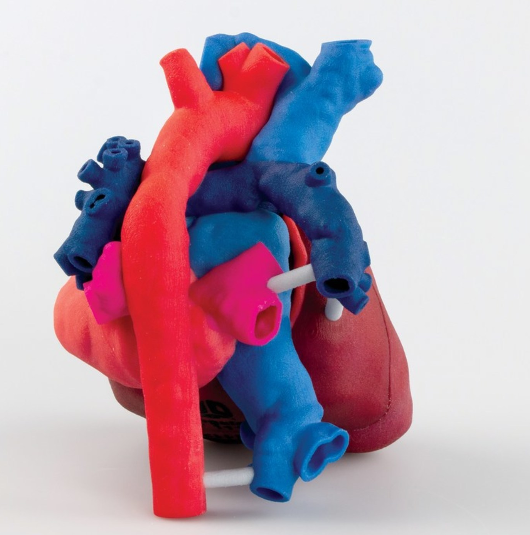

Over the past four years, 3D Systems has leveraged its 20 years of anatomical modeling expertise and medical workflow to help OpHeart produce accurate, detailed 3D printed models of CHD patients for a surgeon’s use. Garcia added:

“We fiercely believe that the ability to 3D print a replica of a CHD patient’s heart is an invaluable tool that can, to put it bluntly, save lives.

“By giving surgeons the ability to practice and plan for complex surgeries that involve reconnecting vessels as thin as human hairs in hearts no larger than a strawberry, it only stands to reason that the quality of surgery improves. We want every child with a life-threatening heart defect to benefit from this technology.”

The Heart-in-Hand Pledge

3D Systems is largely contributing to the Heart-in-Hand Pledge by leading the creation of customised heart models. With the use of its D2P (DICOM to Print) software, the company’s team of expert biomedical engineers is converting MRI and CT scans data of a heart into a 3D model. Following this, the model is printed using ProJet CJP 660Pro ColorJet 3D printer and VisiJet materials. The models are then shipped worldwide.

As there is no insurance reimbursement for these tools, 3D System’s charitability intends to accelerate the Heart-in-Hand initiative in saving children’s lives. Garcia concluded, “Hopefully, they will become the standard of care, as insurance companies recognize their value and reimburse for their use.”

For more on additive manufacturing in the medical sector, subscribe to the 3D Printing Industry newsletter. Also, find us on Facebook and like us on Twitter.

Looking for a career change? Search and post new opportunities across additive manufacturing by visiting 3D Printing Jobs.

Featured image shows a 3D printed heart model. Photo via 3D Systems/OpHeart.