3D Systems has released its new Figure 4 Standalone SLA 3D printer with complementary materials as an adaption of the Figure 4 Production platform which uses an industrial robotic arm for mass production.

With print speeds reaching 100mm per hour and six sigma repeatability, the Figure 4 Standalone is capable of same-day functional prototyping iteration and low volume production. The Standalone does not require a robot arm to operate.

“Repeatability is key when thinking about part production. With our Figure 4 platform – including Figure 4 Standalone – customers have the ability to scale from prototyping to production with unprecedented accuracy and repeatability,” said Vyomesh Joshi, President and CEO of 3D Systems.

The Figure 4 Standalone

The Figure 4 platform was first unveiled at AMUG 2016 in St. Louis, Missouri, as a productive and industrial digital molding solution “for any production environment.” This includes the U.S. Air Force supply chain for which the platform is currently used to 3D print aircraft components across a range of older planes. Furthermore, NextDent has enabled dental material compatibility on the platform allowing the fabrication of 20-30 crowns in under 15 minutes.

The platform comprises of a control cell, four 3D printing cells, and a post-processing cell representing the steps in an assembly line. An industrial robotic arm is used to pull a print up from a vat of resin as it is cured layer by layer at rapid speeds at stage one of the process.

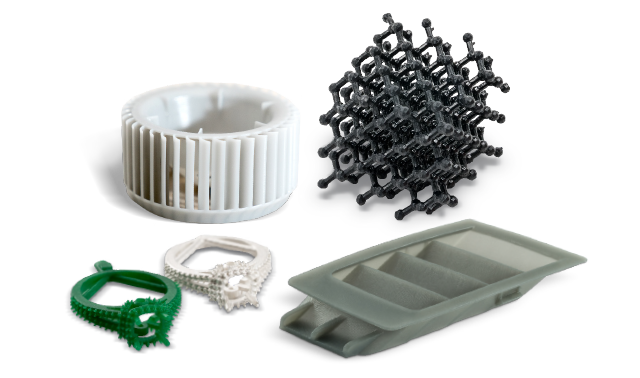

Nonetheless, seeking to create a more compact, accessible and ease-of-use system, 3D Systems created the Figure 4 Standalone. A portfolio of complementary high-strength plastics including Figure 4 TOUGH-GRY 10, Figure 4 TOUGH-GRY 15, Figure 4 ELAST-BLK, and Figure 4 JCAST-GRN have also been developed for the new 3D printer.

A beta-testing customer for the Figure 4 Standalone, Dana Taylor, an Engineer Consultant for LumiraDx, a manufacturer of diagnostic medical devices stated:

“We were able to get functional prototype parts in hours for same-day testing as compared to what used to take a week or more by using outside print services. In addition to speed, Figure 4 Standalone prints parts are ready to use with an exceptional surface finish, accuracy and tight tolerances needed for fit, form and function testing.”

Figure 4 Standalone technical specifications and pricing

| Build Volume | 124.8 x 70.2 x 196 mm (4.9 x 2.8 x 7.7 in) |

| Maximum Resolution | 1920 x 1080 pixels |

| Weight (crated) | 59 kg (130 lbs) |

| Materials | UV curable plastics: Figure 4 TOUGH-GRY 10, Figure 4 TOUGH-GRY 15, Figure 4 ELAST-BLK 10, Figure 4 JCAST-GRN 10 |

| Operating Environment Temperature Humidity (RH) | 18-28 ºC (64-82 ºF) 20-80% |

| Electrical | 100-240 VAC, 50/60 Hz, Single Phase, 4.0A |

| Pixel Pitch | 65 microns (0.0025 in) (390.8 effective PPI) |

| Power Requirements | 208VAC 3 phase, 50/60 Hz, 18 Amps |

| Software | 3D Sprint, 3D Connect |

“Figure 4 Standalone is enabling customers to address a broad range of applications with speed, accuracy, and repeatability – helping them redefine their manufacturing workflows from initial part design to end-part production to maintain their competitive advantage,” added Joshi.

3D Systems’ Figure 4 Standalone is currently available and priced at $21,900 (US)/€19,900 (EU Countries), £18,900 (UK).

For more of the latest 3D printing news subscribe to the 3D Printing Industry newsletter and follow us on Twitter, and Facebook.

Pursuing a career in additive manufacturing or looking for skilled individuals in the field? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the Figure 4 Standalone 3D printer curing process. Clip via 3D Systems. Photo via 3D Systems.