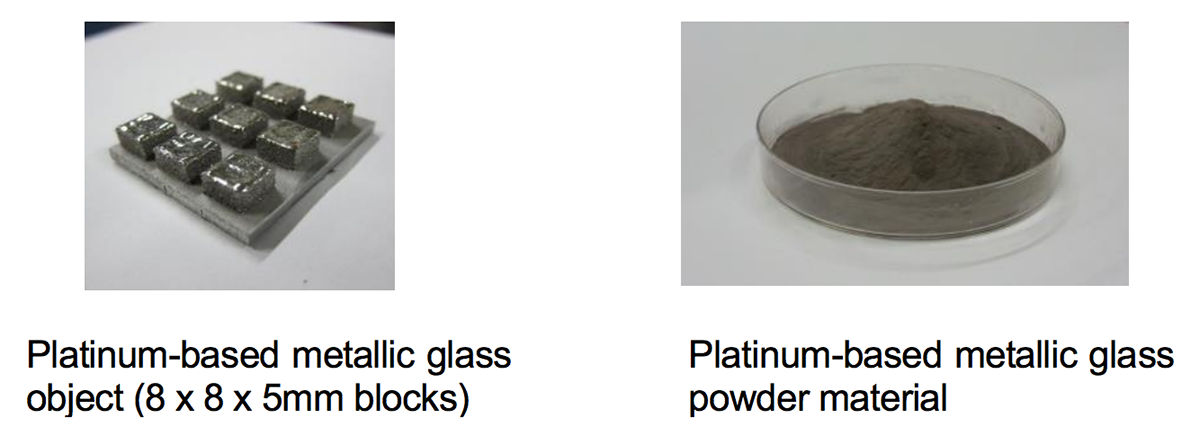

The Technology Research Institute of Osaka Prefecture conducted joint research with Tanaka Holdings to develop the optimum melting conditions and powder grain shape for use with the SLS process. The collaboration resulted in the successful 3D printing of an object using platinum, platinum-based metallic glass and a nickel-based alloy with iridium additive. Tanaka believes that this is the first time anyone has created platinum-based metallic glass material suitable for 3D printing.

Tanaka Holdings parent company Tanaka Kikinzoku Kogyo received a patent for their platinum metallic glass in 2004, however it took them almost a decade to perfect the optimum particle diameter and fluidity for use with existing SLS 3D printers. This was ultimately achieved by using the company’s own proprietary equipment and processes.

Metals in the platinum group are highly sought after for usage in the electronics, semiconductor, automotive and aerospace industries due to its durability and high melting point; however, many platinum alloys have limitations because of the inability to form complex shapes with traditional methods. Being able to 3D print objects using powder materials means that users will now be capable of forming objects with extremely complex shapes and dimensions.

Platinum-based metallic glass is regarded as a next-generation material and is quickly gaining attention for a large variety of useful properties, including its extremely hard and smooth surface, low flexibility, high corrosion resistance, friction and scratch resistance, precise casting and low vibrational properties. Corrosion resistance, especially for medical materials, is one of the main benefits of 3D printed platinum products, as is the high heat tolerance for use in engine parts for the automotive and aerospace industries.

Tanaka Holdings will be exhibiting at International Powder Technology Exhibition – POWTEX – Tokyo where they will showcase their new platinum materials from today through Friday. Tanaka will make samples of the material available to interested customers at the beginning of December.