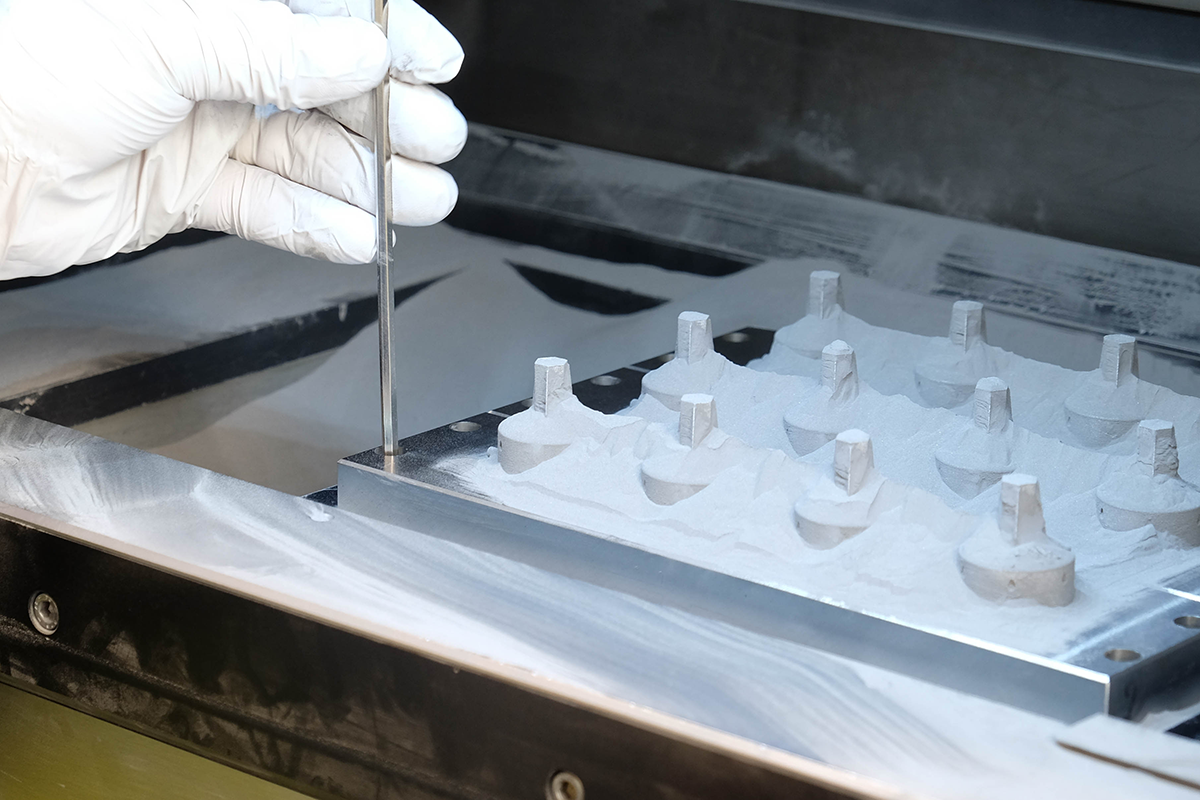

Philips brand Smit Röntgen has announced that it is now the first company to offer additive manufactured Tungsten parts. The medical imaging component manufacturer is using Powder Bed Laser Melting to create pure Tungsten products. The proprietary laser melting technology requires just forty-eight hours to turn a computer aided design file into a tangible product. Smit Röntgen says that the technology allows for the high volume production of pure Tungsten parts.

Medical imaging component manufacturer Smit Röntgen has become the first EOS GmbH service provider for pure metal Tungsten. There has been an ongoing collaboration between the two companies that has resulted in a custom designed version of the EOS M280 additive manufacturing (AM) machine capable of the mass-production of the Tungsten parts.

Dr. Adrian Keppler, Chief Marketing Officer at EOS said: “There is a high potential for applications using refractory materials. EOS together with Smit Röntgen started very early to develop a solution that is able to process this material. We are pleased that Smit Röntgen with its high AM expertise is offering the EOS technology to new customer segments too.”

The EOS M280 has been installed and is now operational. The M280 has been made suitable for mass-production and boasts a high beam quality and performance stability. Harry Kleijnen Head of Development Smit Röntgen said: “This equipment and the extensive process knowledge developed, lifts additive manufacturing to a new level of maturity.”

The specifications of the machine and it’s benefits are as follows:

Maximum product size: 230 x 230 x 200 mm

Minimum feature size: 100 um

High aspect ratios: 1:300 possible

Short design cycle ensures process optimization

Small product adaptations can be made easily to optimize the design for assembly

High flexibility in product design

The Tungsten Powder is fully recyclable

Smit Rontgen are a long established company with a history that goes right back to 1930, now truly ultra-modern with an announcement that represents another pivotal breakthrough in materials for contemporary additive manufacturing. You can find out more about the process and brand at the Smit Röntgen website.