This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

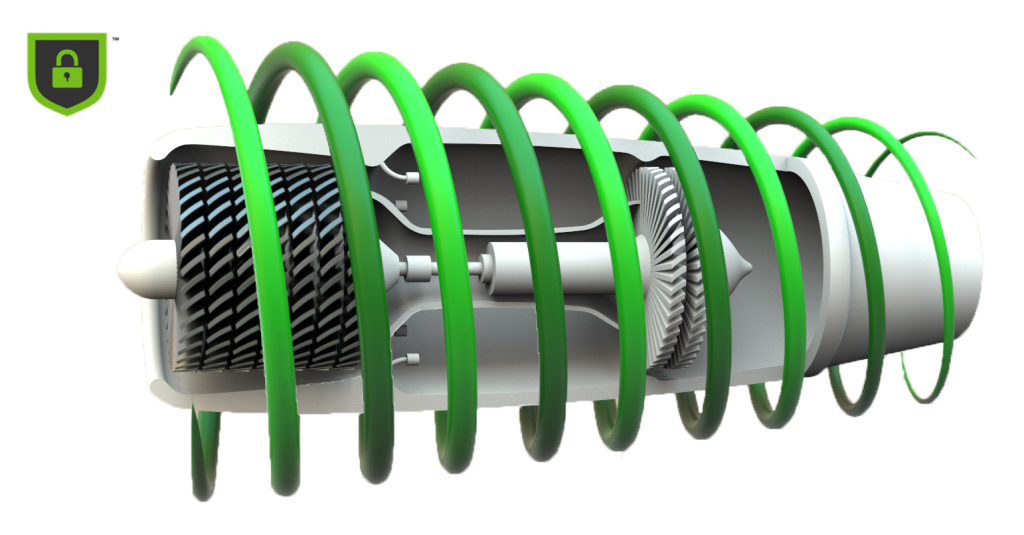

Stephan Thomas is the co-founder of Identify3D. The Identify3D digital supply chain platform provides design protection, quality assurance, and data logistics for digital manufacturing. The California based company recently won the Innovation Award at RAPID 2017.

3D Printing: the next 5 years by Stephan Thomas, co-founder of Identify3D

Predicting the future by looking at the past

So, where were we in 2011? 3D printing was a concept largely confined to R&D departments. According to the Wohlers report, the market was about $1.6 billion and at that time the prediction for the market was to reach $5.7B in 2017 and about $10B in 2021, a 21% CAGR.

Fast forward to 2017 and the market is about $8.8B, 4.5 times larger than 2011 and 54% greater than estimated. There is only one thing certain with 5 year predictions: they will always be wrong, even if directionally correct. If we apply the similar margin of error then the 3D printing market will be a lot bigger than the $26.5B projected for 2021. Or perhaps even greater than $50B.

A revolution or an improvement?

So what? That figure is still a very small number compared to the $12+ trillion manufacturing market, so is the disruptive technology that was going to revolutionize the manufacturing world nothing more than an incremental improvement?

A revolution is a drastic change that may take years to form before happening and we may still be in the infancy of a revolution. To fully transform the manufacturing sector, quantum leaps have to happen in three key areas: software, hardware and materials to be able to deliver what is needed for be considered a fully disruptive technology.

Creation of products that can not be manufactured any other way that will either create new markets or fully replace existing products. This will lead to a reduction of costs in the value chain from product design to delivery and the enablement of new business models.

Leaps in innovation

My prediction is that we will see leaps in innovation in all of three of these areas within the next 5 years enabling new markets utilize additive technologies.

Carbon and HP have already claimed massive improvements in technology, claiming 10-100X improvement in printing speed. Could we see a metal CLIP equivalent technology in the next 5 years that will deliver the next level of speed and quality? Could we see a technology that will either greatly reduce or eliminate post-processing costs? Likely and we should plan for it.

CAD and CAM now have specific Additive Manufacturing components, i.e. NX AM. A new breed of testing, optimization and simulation software is appearing – after all, Magics, one of the leading 3D printing specific software, just came out in 2010.

Furthermore, machine manufacturers have stepped up their game when it comes to software. For example Renishaw’s QuantAM and EOSPrint/State.

Of course, the list of materials in the last five years went from fairly limited to quite diversified. Companies like Arconic/Alcoa are leading the way in the next level of titanium, nickel and aluminum powder.

In 2011, Stratasys and 3D Systems, 2 medium sized companies at the time, were the big names in 3D printing. In 2016 HP, Siemens, GE, Airbus are driving innovation and M&A. And in 2021, will Google, BMW, Tesla, Amazon, Hershey, UPS or DHL be ahead?

The future of 3D printing

Because of the large investment flowing in the 3D printing space, especially industrial, we can expect a lot of innovation and additive manufacturing as a dominant technology for the manufacturing of high value production parts.

We will have new products that could not have been manufactured in any other way, new business models in which revenue are driven through product data not physical products, new market entrants. Hospitals, the Military are looking at re-inventing themselves as manufacturers while manufacturers are transforming themselves as IT companies managing large amounts of data.

In 5 years the challenges of 3D printing will move away from today’s material constraints, build envelope, speed, post-processing to management and control of large data flows from design to manufacturing to in field uses.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels. Let us know your thoughts about this perspective on the future of 3D printing in the comments below.

More information about Identify3D is available here.

#futureof3Dprinting

Featured image shows Stephan Thomas and Joe Inkenbrandt co-founders of Identify3D.