UK based engineering company Renishaw (LON:RSW) first released their QuantAM software in November 2015. The software is specially designed to work with the company’s industrial selective laser melting (SLM) machines and serves as the translator between CAD models and 3D printed objects.

The newly announced 2017 edition of Renishaw’s QantAM software brings improvements to the slicing, support, and simulation of models for 3D printing.

3D part orientation

QuantAM software accepts 3D files in an .stl format from any 3rd party software. After importing the object, users are taken to the orientation of the part on a build plate. In this initial step, QuantAM helps users select the best direction to 3D print an object, i.e. lying down or on its side, to decide the grain of the object and where its strength will lie.

Enhanced support

Next, support structures are introduced. Initially done automatically, the 2017 update to QuantAM adds angled tree and cluster supports that can be edited by the user. The advantage of this feature is that engineers can optimize the design for post processing, and where an object may need extra strength.

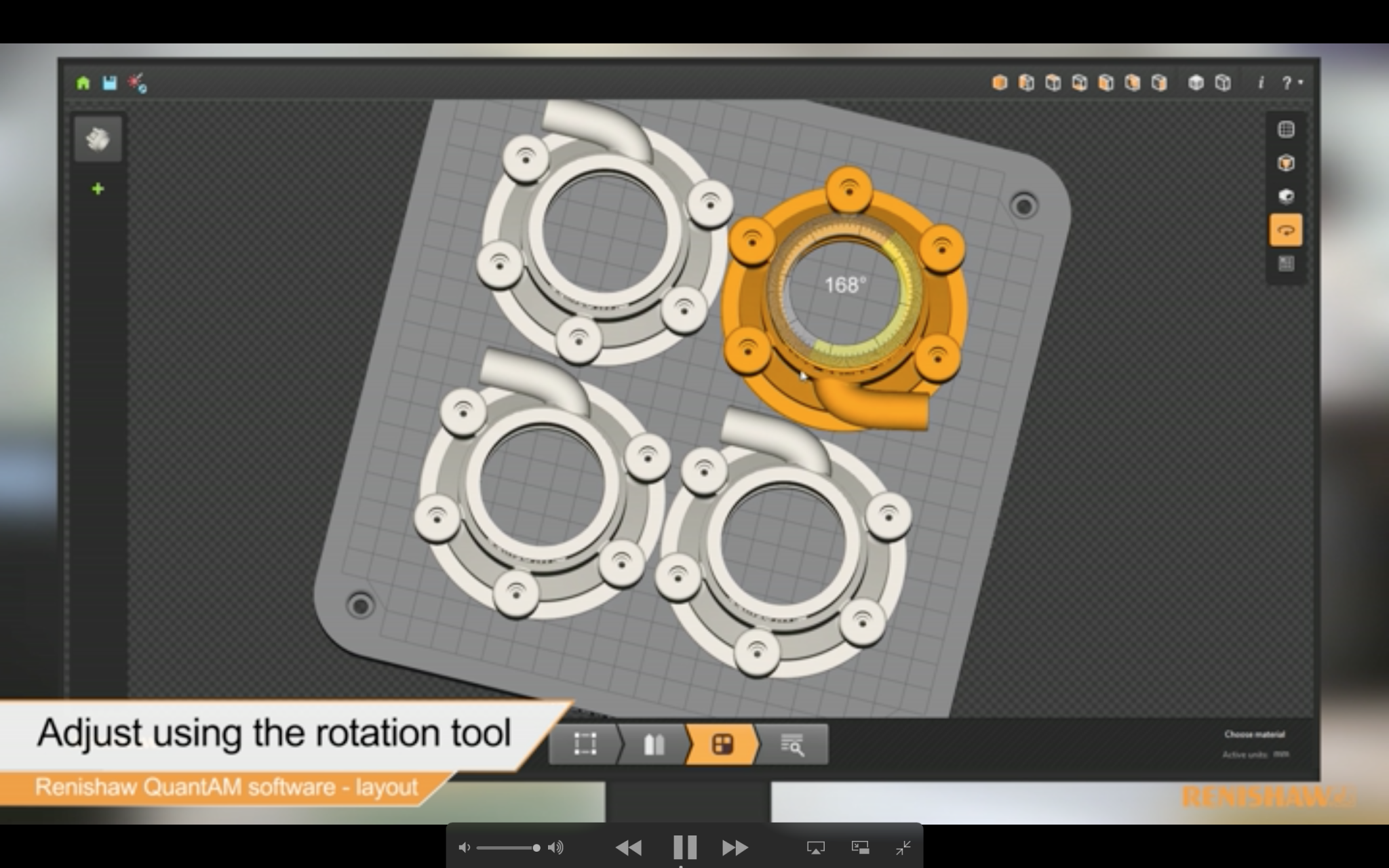

3D printer-bed layout

After this, the layout is decided. Multiple parts are placed into a specified build area to ensure optimal coverage and no interference between parts. The 2017 update is also improved for parts stacked on top of one another.

Quality control

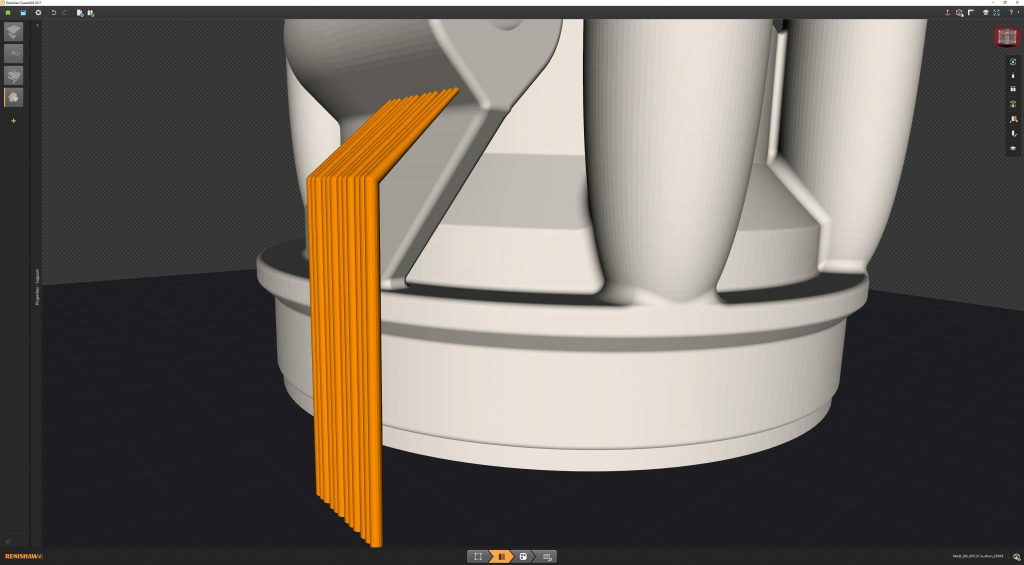

And finally, the 3D model enters the review stage, where users look for imperfections in the 3D model and simulate how each layer is going to print. The 2017 ‘Navicube’ feature is helpful in this step as it allows users to view parts from all angles. The open parameter editing tools also allows accurate visualization of how objects will 3D print in specific metals.

3D software improvements across the board

At the 3D Medical Expo in Maastricht, 3D Printing Industry previewed Renishaw’s ADEPT Project software specially designed for 3D printing medical implants. The concept behind ADEPT is that users don’t have to be design experts to make, for example, a metal plate. The software is more useful if is can be manipulated by surgeons who will be performing operations and have knowledge of how a plate should fit.

As discussed by Marc Saunders, Renishaw’s director of Global Solutions Centers, at IMTS 2016, the company are capitalizing on the somewhat underdeveloped area of Design for Additive Manufacturing (DfAM) in their updated software releases. In this way they are completing the trifecta of 3D printing that essential to the industry’s development. Without software, the materials and hardware cannot achieve their full potential.

To stay up to date on the latest 3D printing software releases you can sign up to the 3D Printing Industry newsletter here.

Featured image shows a complex manifold part showing a slice layer in QuantAM software 2017. All images featured in this article are courtesy of Renishaw