In this edition of 3D printing news Sliced, we have stories from Ultimaker, KAUST, The ModuLase Project, Johnson Matthey, voxeljet, UbiSoft, Water Pik, LulzBot, SABIC, Sharebot, Organovo, DMG, Dentalica, US Marine Corps Explosive Ordnance Disposal, Shining 3D and Pointshape.

A boost for Ultimaker, expansion for Shining 3D, and a cut for Organovo

Netherlands-based OEM Ultimaker has been provided with an undisclosed amount of capital from private equity firm NRM Capital. Under the agreement, NRM’s parent company, SHV Holdings, will become the majority shareholder, while Ultimaker’s founders will remain as shareholders. The capital will go towards global expansion marketing and R&D resources.

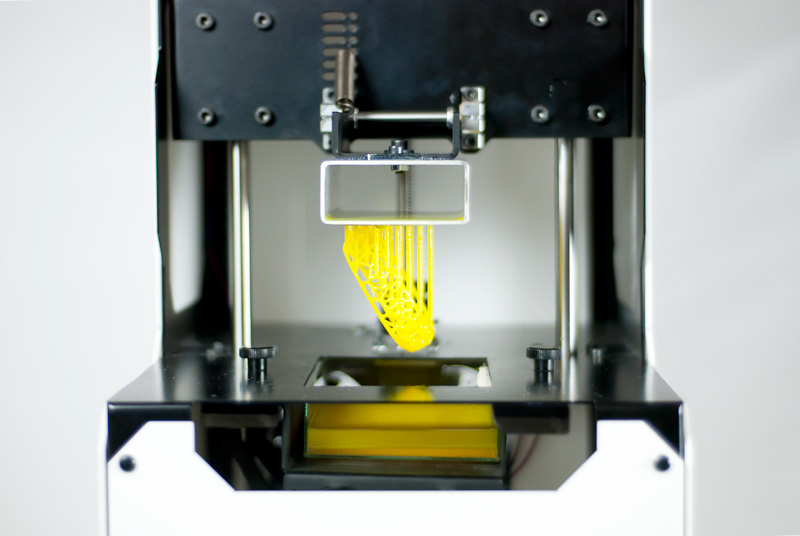

Medical research and 3D bio-printing company Organovo is to cut 13% of its workforce, equating to roughly 15 positions, following the release of its preliminary Q2 revenues. With the restructuring, the company says that it hopes to cut operating costs by $1.3M in the fiscal year 2018, followed by $2.7M in the fiscal year 2019. Organovo co-founder and CEO Keith Murphy left that position in April 2017, while fellow co-founder Gabor Forgacs and former Chief Scientific Officer left in 2011.

Forgacs is currently CSO at Modern Meadow, a company that initially touted itself as 3D bio-printing but has since pedalled back on these earlier statements. Natalia Krasnodebska, Modern Meadow Head of Communications, writes “Modern Meadow has never used 3D printing.”

Following recent partnerships with Geomagic and Verisurf, Shining 3D has now partnered with engineering software company Pointshape, making the PointShape Inspector Full version and the PointShape Inspector Lite version available to all SHINING 3D users.

Illuminating braces, a splash of oral hygiene, and Sharebot going dental

Scientists from the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia have developed an orthodontic system which combines a 3D printed smart dental brace (made of biocompatible, semitransparent Clear Resin 1 L (GPCL02), and a set of 236 μg flexible Lithium Ion batteries. The batteries power near-infrared LEDs interconnected on a soft PET substrate. The LEDs provide light therapy, which controls osteogenic cell activity, and enhances the bone regeneration.

Water Pik, a manufacturer of irrigation-based oral hygiene systems has been supplied with 3D printers by Colorado based OEM Lulzbot. Using their three Lulzbot TAZ 6 3D Printers, Water Pik is creating quality control testing and conducting product development using their 3D printed products.

Sharebot, an Italian OEM has welcomed dental distributor and Dentalica and dental systems manufacturer DMG as shareholders. As part of the Sharebot team, the Dental firms added resources will be used in global marketing and R&D.

Intricate ceramics and super strong filaments

Johnson Matthey’s new UK ceramic binder jet 3D printing facility is to be supplied by OEM voxeljet. The binder jetting specialist will continue to provide Johnson Matthey with printers to create complex geometries for ceramic 3D printing.

The Saudi Basic Industries Corporation (SABIC), a Riyadh-based chemical company, is to launch a specialised FDM filament at Formnext 2017. Details about the material of this “high-impact strength” filament have not yet been released.

Blasts and Lasers

The ModuLase project, a collaboration between QSYS (The Netherlands), ULO (UK), AIMEN (Spain), EWF (Belgium), CRF (Italy), SODECIA (Germany) and GEL (UK), is aiming to develop a reconfigurable laser process head, that is capable of welding, cladding and cutting. ModuLase is developing a Beam Forming Unit capable of being where Energy Distribution is capable of being tailored, and a number of ways of improving laser cladding for additive manufacturing.

The US Marine Corps Explosive Ordnance Disposal (USMCEOD) has found success in 3D printing small explosives. The devices were printed in less than 24 hours, and then packed with explosive charges. The marines will now investigate their applicaiton in the field.

And finally, 3D printing goes to Cleopatra’s Egypt

Hobs Studio in London has teamed up with game developer UbiSoft to create the first ever 3D printed life size ancient Egyptian sarcophagus. Literally meaning “flesh eater”, the sarcophagus was a funerary casket to store mummies of Egyptian royalty and nobles used all the way from Old Kingdom Egypt until Roman times.

While the wooden box of the replica sarcophagus was CNC milled from wood, the other details of the casket were 3D printed using SLA, before a designer finished off the delicate paintwork and a TV screen and XBOX One were mounted on it. The aim of the project is to promote Ubisoft’s new game Assassin’s Creed Origins, set in Ancient Egypt during the time of Cleopatra.

For regular updates on applications and business in the 3D printing world, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows an Organovo bio-printer 3D printing tissue. Photo via Organovo.