In this edition of 3D printing news Sliced, there are stories from the Joan C. Edwards School of Medicine, Marshall University, MIT, Aether, Poly 6, Shining 3D, Verisurf, Carbon, Aerojet Rocketdyne, Frontier Microscopy, Arcam, Joe Te Wharau, Goddards Centre Tauranga, Iowa State University and Kinazo Design.

3D printing in and out of the hospital

Joan C. Edwards School of Medicine at Marshall University in Huntington, West Virginia, has purchased a 3D printer together with photosensitive resin and polylactic plastic. The printer is now being used by technician Matthew W. Crutchfield to create trainiang devices on which medical students can practice and for imaging systems. The printer was bought using a $10,000 grant from The Huntington Clinical Foundation.

Bio-printing OEM Aether has announced that its Aether 1 bio-printer will be used exclusively for a biomaterials module on MIT’s Materials, Societal Impact and Social Innovation course. The module is based on Citrene, a bioplastic made from citrus rinds that was developed by Poly6, an MIT spin-off company. The MIT students on the course will use Aether 1 to investigate potential medical applications for Citrene.

Expansions all round

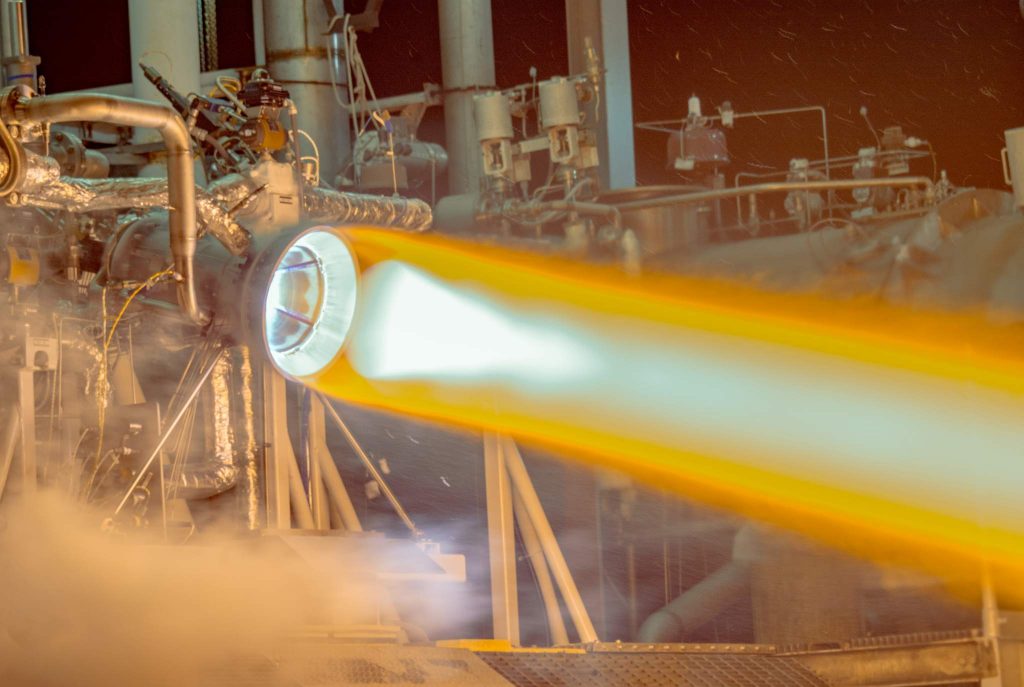

Aerospace and defence manufacturing company Aerojet Rocketdyne has announced that ground has been broken on the site of its Advanced Manufacturing Facility, which will house its defense business unit in Huntsville, Alabama. The facility will use additive manufacturing alongside proofing and composite modelling for its work on space defence projects.

Phoenix Analysis and Design Technologies (PADT), based in Tempe, Arizona, has purchased 3 M2 3D alongside printers from Silicon Valley based OEM Carbon. PADT will use the DLS printers for its parts manufacturing service. As part of the purchase partnership, PADT will join Carbon’s Production Partner Program.

Swedish OEM Arcam has announced that it is launching a preferential rights issue of 4,109,286 ordinary shares. The company’s existing shareholders will be given the opportunity to purchase a specific number of securities at a specific price (detailed within the company’s prospectus) during the subscription period of 25 October 2017 – 9 November 2017. This announcement follows the news that GE, Arcam’s parent company, was set to make $20 billion worth of cuts following poor market performance.

Asbestos detection and reverse engineering.

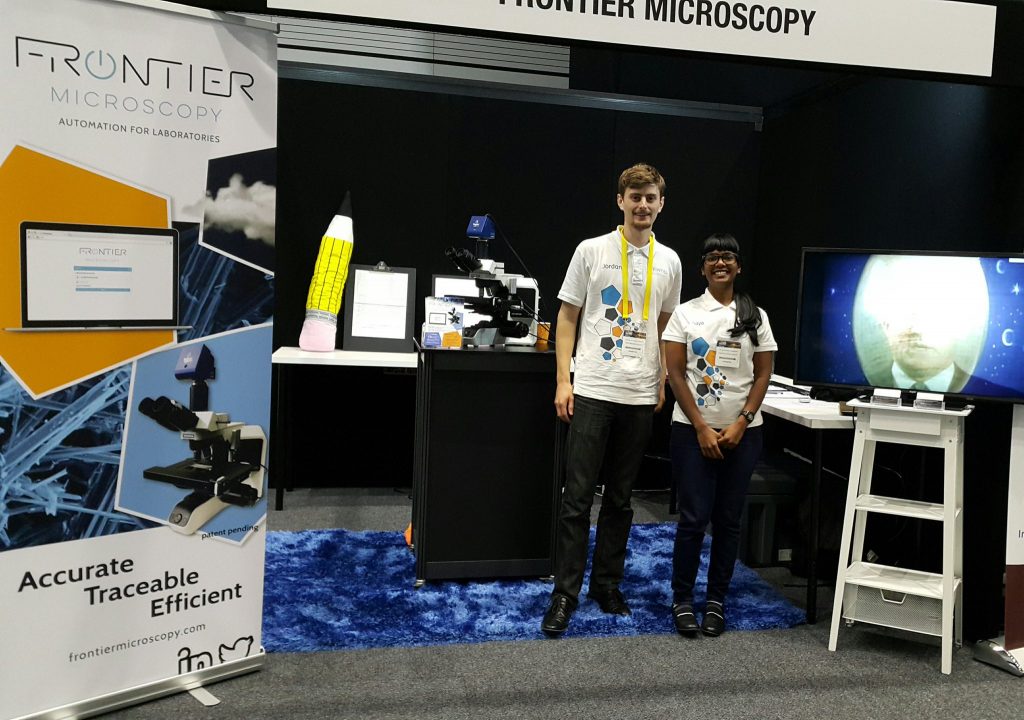

“Marvin the Microscope” is a device developed by Austrialian engineer Jordan Gruber, of startup Frontier Microscopy, to monitor and detect asbestos fibers across an air filter sample. Gruber adapted a standard laboratory microscope using specialist 3D printed parts, which enable connectivity to computers running Frontiers asbestos detection software. With a growing team Frontier now hopes to make Marvin more widely available for safety applications

Shining 3D has partnered with two 3D software providers to extend the capabilities of its Einscan 3D scanner range. The partnerships, with Geomagic and Verisurf, will offer Einscan 3D customers a discount on the reverse engineering software bundles.

DIY Nintendo, electric bike, and keeping the traditions alive

Tim Lundqvist, who is an electrical engineering student at Iowa State University has built a Nintendo Switch console using a Raspberry Pi computer and a 3D printed casing almost identical to the look of the original. The Raspberry Pi computer runs the RetroPie game emulation platform, allowing retro games not usually available on the switch to be played on Tim’s “Nintimdo RP”.

Slovakian studio Kinazo Design has produced an electrically powered mountain bike with a 3D printed frame, retailing at a currently steep €20,000. However, the bike’s mere mass of 20kg, the integrated battery in the frame, and single element frame makes it stand out. To 3D print the bicycle, Kinazo made use of the Volkswagen Slovakia plant’s large format 3D printer, which has a build volume of 80 x 40 x 50 cm.

Joe Te Wharau is a mixed media artist who has combined traditional Māori designs with modern technology to produce “Matihiko Taonga V1.0” (“Digital Treasuries V1.0”), on display at the Art of technology exhibition in New Zealand. Among the nylon 3D printed pieces are “tiki” (figure) and “taonga” (treasure) pieces, some of which are embedded with computer chips. “Māori communication is visual and spoken”, Te Wharau explained, “these pieces are a translation of Māori tradition through modern technology, and I think it’s a natural progression”.

The Art of Technology exhibition is part of the Tauranga Arts festival and takes place in the Goddards Centre Arcade in Tauranga, New Zealand, until the 5th November.

For daily summaries of everything going on in the world of 3D printing, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a 3D printed taonga piece on a chain. Photo via Joe Te Wharau.