November was the month of one of the largest additive manufacturing show formnext. 3D Printing Industry team was in Frankfurt bringing our readers the latest news from the exhibition.

From formnext 2018

Fillamentum, a Czech 3D printing filament manufacturer worked with František Dvořák, an industrial designer, to 3D print a hood of an electric motorbike. The hood is made of sixty-six parts all 3D printed using the CPE filament (PET) provided by Fillamentum. The bike was exhibited at formnext 2018.

Dutch manufacturer, Builder 3D Printers, introduced a large-format 3D printer at this years formnext. The Extreme 2000 PRO is an FDM/FFF printer with a massive xy dimension: 1700 mm.

Against obsolescence

In recent times, 3D printing technology has led the fight against part obsolescence. In November, the Whirlpool Corporation, a multinational manufacturer of home appliances, partnered with Spare Parts 3D, a Singapore-based 3D printing service bureau.

An application of 3D printing against obsolescence in the automotive industry also made the headlines. Mercedes-Benz is 3D printing parts of classic cars for its customers. The parts can be ordered from the Mercedes-Benz Classic Center. The Center will 3D print and ship parts for the 300 SL Coupé, SL Roadster, W110, W123, W111 and W112 models.

Furthermore, the 3D printed parts have been modified according to modern automotive standards. For example, the inside mirror base of the 300 SL Coupé now sits lower than it did before. This is to provide a clearer back view.

In November, we also reported the Twikit-enabled BMW MINI customization platform.

3D printed Humanoids

Youbionic One, an Italian start-up maker of unique 3D printed assistive devices, Humanoids, made a centaur-like robot in collaboration with Boston Dynamics. The 3D printed robotic arms by Youbionics were attached to the headless robotic dog, SpotMini, designed by Boston Dynamics. The 3D printed arms by Youbionic forms the upper body of the SpotMini.

The gun hype

3D printed guns went to court again. In November, Frank Pallone the U.S. Representative for New Jersey’s 6th congressional district, proposed a bill to ban 3D printed guns. The bill addresses, in particular, a prohibition of distribution of digital gun kits and parts through electronic media.

Regenerative medicine

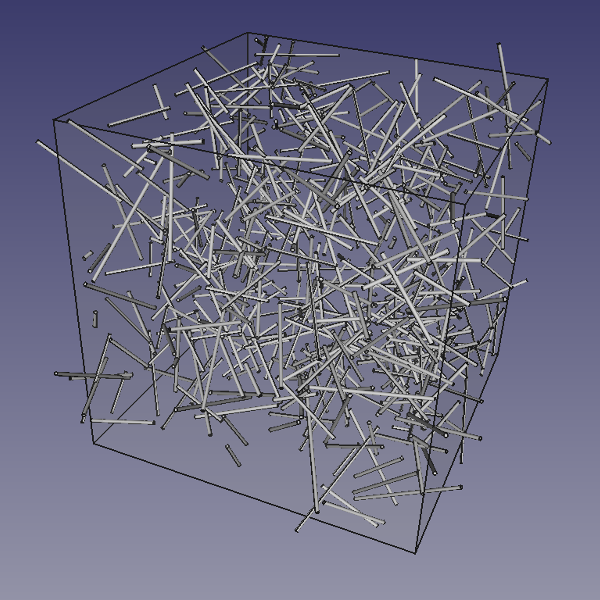

3D printing has opened avenues of research in bioprinting and regenerative medicine. In November, it was reported that 3D printed scaffolds and stem cells will be used to heal bones. University of Arizona’s (UA) Dr. John A. Szivek, a biomedical engineer will lead the five-year-long project that will help veterans.

According to Robert C. Robbins, President of the UA, the project is “an incredible example of the kind of innovative research that is made by possible by technological advancement through the convergence of the biological, physical and digital worlds … a great example of using new technology to significantly improve quality of life for patients.”

Saving the planet

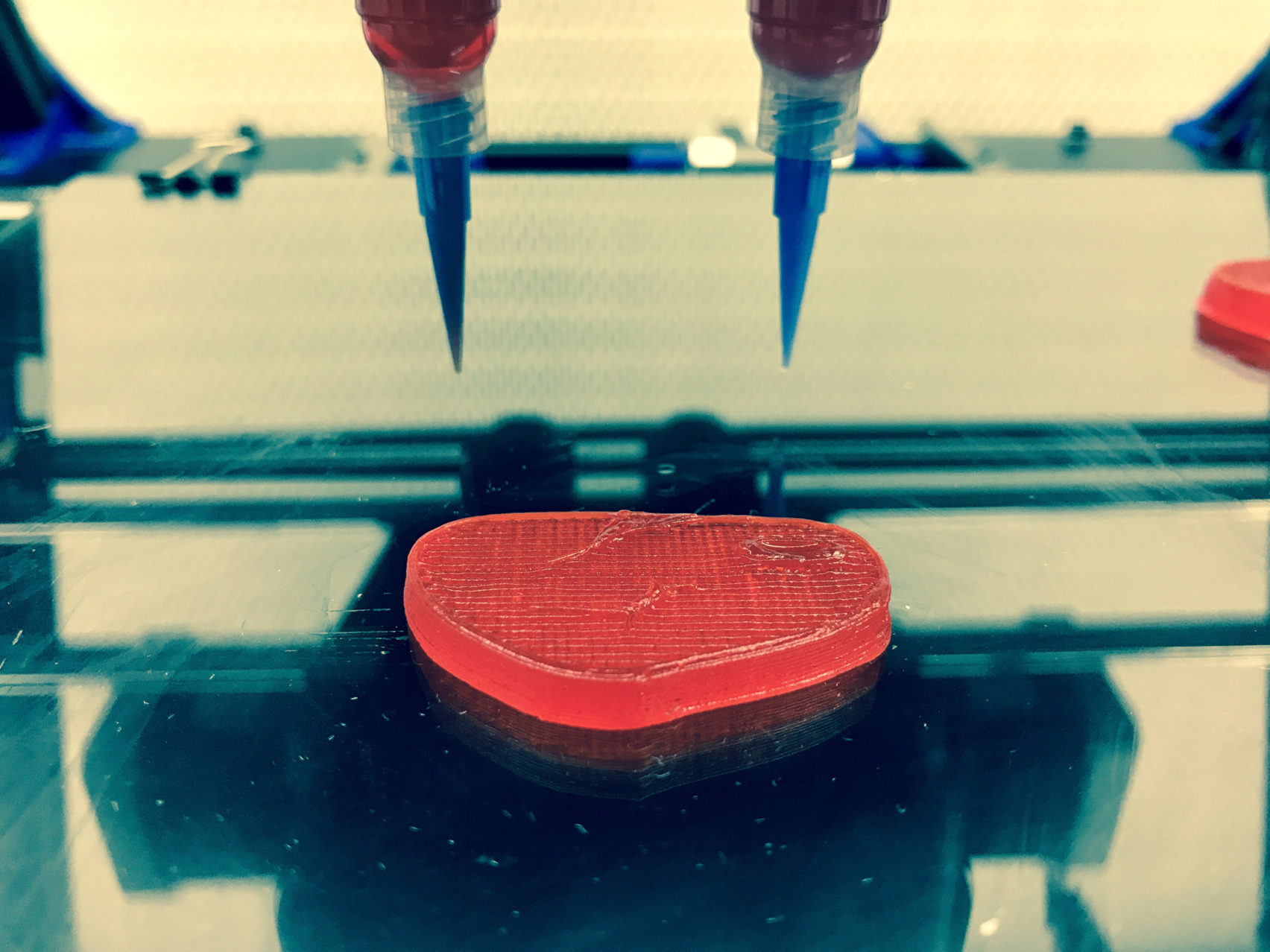

Novameat, a Barcelona-based bioengineering start-up 3D printed a vegan steak. The steak replicates the texture of real meat. Giuseppe Scionti, a bioengineer and the founder of Novameat created a 3D printable paste with rice, peas and seaweed protein. The paste was then used to 3D print the piece of steak. The effort is to promote meat-free food and reduce animal farming.

Faster and stronger

Origin, a California-based start-up, received $10 million in a series A funding round led by BASF, the largest chemical producer. Origin has an open approach to materials, which the company believes is the key to unlocking mass manufacturing with 3D printing technology.

Dr. Adrian Bowyer, the award-winning inventor of the self-replicating 3D printers, described a way to make 3D prints stronger. Dr. Bowyer, suggested that if we add hollow tubes to the inside of a part where a slicer does not generate infills. “When the part is sliced the slicer will surround the cylinder with solid material automatically, making it like a length of strong fiber embedded in a weaker material (the print’s infill),” Dr. Bowyer explained.

3D Printing Awards 2019 are near, please take a moment to make your nominations.

We have more news on additive manufacturing, subscribe to our 3D printing newsletter. You can also follow us on Facebook and Twitter.

We also have exciting careers in the industry, visit our 3D Printing Jobs site for more information.

Featured image shows a Mercedes-Benz 300 SL Coupe. Image via Mercedes-Benz