In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features several new 3D printing partnerships, material qualifications, 3D printer updates, and how one aerospace firm is taking steps to win the space race.

Read on for the most recent updates from SLM Solutions, BASF, SISMA, Usmih, Velo3D, Farsoon Technologies, and more.

New 3D printing partnerships from TRUMPF, Sinterit, and Photocentric

Kicking off this week’s partnerships updates is German machine tool manufacturer TRUMPF, which has taken over its joint additive manufacturing venture with Italian 3D printer developer SISMA. First announced in November, the now-closed deal sees TRUMPF take full control of TRUMPF SISMA S.R.L., the Laser Metal Fusion (LMF) 3D printing business it founded alongside SISMA.

Going forwards, TRUMPF will continue LMF business activities within the industrial, dental, and medical markets under the name TRUMPF Additive Manufacturing Italia, which will remain headquartered in Schio, Northern Italy. SISMA, meanwhile, will focus on the jewelry and fashion industries and distribute LMF machines from TRUMPF to these markets.

Meanwhile, Polish 3D printer manufacturer Sinterit has announced a new partnership with Forward AM, the 3D printing arm of global chemical firm BASF. The two companies will work together to jointly develop SLS 3D printing materials, hardware, and industrial applications.

“A prerequisite for a large increase in the potential of this technology is new applications that can be opened by materials,” Konrad Glowacki, Sinterit Co-founder responsible for product management. “In cooperation with BASF Forward AM materials, Sinterit will introduce work-ready materials with the Lisa and the NILS lines.”

Elsewhere, 3D printer and materials manufacturer Photocentric has teamed up with Ukrainian dental aligner specialist Usmih to develop an innovative 3D printing process for manufacturing dental aligners. While both companies are remaining tight-lipped about how the method works, we do know that it will leverage Photocentric’s LC Magna 3D printers and resins in tandem with a conveyor belt process to rapidly cure aligner models. According to Usmih, the process will be ready for full production by the start of Q1 2022.

“The production of clear aligners remains one of the fastest-growing areas of 3D printing today, and together with Usmih we are working on transforming the efficiency and reliability of its in-house process, from start to finish,” said Sally Tipping, Sales Director at Photocentric.

“Usmih has been able to call upon our extensive expertise spanning hardware, materials and industry knowledge, to come up with a solution that has the potential to deliver compelling benefits to its already successful enterprise.”

Materials updates from Desktop Metal and Velo3D

Moving onto materials now, and binder jet 3D printer manufacturer Desktop Metal has introduced a new high-strength stainless steel alloy for its Production System platform, named DM HH Stainless Steel. Combining high strength and hardness with corrosion resistance, the alloy will enable users to produce DM HH-SS components at scale for industries such as oil and gas, automotive, consumer products, and medical devices.

Notably, DM H-SS combines the tensile strength, ductility, and corrosion resistance of 13-8 PH stainless steel with the added benefit of improved hardness comparable to low-allow steels such as 4140, making it an ideal choice for injection tool core and cavity applications where millions of injection strokes per year are required. With the addition of DM HH-SS, Desktop Metal’s Production System can now print 10 qualified metal materials.

Meanwhile, metal 3D printer manufacturer Velo3D has qualified the nickel-based superalloy powder Amperprint 0233 Haynes 282 for use on its Sapphire 3D printers. Produced by global metal powder producer Höganäs and under license from Haynes International, the powder is designed for high creep strength, thermal stability, weldability, and fabricability not commonly found in other alloys, according to Velo3D.

The powder’s properties make it ideal for high-temperature structural applications within energy generation, like gas turbines, and to build heat exchangers, combustors, nozzles, rocket engines, and impellers for space launch vehicles. Oklahoma-based contract manufacturer Duncan Machine Products will be the first to utilize a Sapphire system with the new superalloy.

“It’s inspiring to see what engineers have been able to build using metal powders from Höganäs and Velo3D’s support-free additive manufacturing process,” said Jerome Stanley, Höganäs Director of Global Sales, Customization Technologies. “The first parts printed using our Amperprint 0233 Haynes 282 powder are impressive, and I believe customers are only scratching the surface of what is possible with this superalloy.

“The powder, combined with Velo3D’s end-to-end solution metal AM solution, is an extremely effective combination for consolidating parts into monolithic structures to eliminate coefficient of thermal expansion in large, high-performance systems.”

Freemelt receives second US order

Business news now, and Swedish metal 3D printer manufacturer Freemelt has received a second order from the US for its Freemelt ONE system. The University of Texas at El Paso will use the system to carry out material research, which will be delivered during the first quarter of 2022.

“The acquisition of the Freemelt ONE open-source electron-beam powder bed fusion system will expand the existing capabilities in the W.M. Keck Center for 3D Innovation at UTEP, to propel research in various aspects of additive manufacturing, including new materials and monitoring, and furthering opportunities for students to engage in research experiences”, said César A. Terrazas-Nájera, Assistant Professor of Research at the University of Texas at El Paso.

BCN3D introduces 3D printer autocalibration

Barcelona-based FDM 3D printer manufacturer BCN3D has introduced autocalibration to its 3D printers which reduces calibration time for customers by 85 percent. The firm’s new electronics system controls a piezoelectric sensor which detects pressure to accurately measure the exact distance between the nozzle tip and the printing surface, while also ensuring the perfect XY alignment for the printer’s dual extrusion system.

BCN3D also announced its Metal Pack is now available for purchase, enabling customers to create stainless steel parts in a three-step process, and its latest material addition, a fiber-filled filament PET CF15.

Farsoon’s Flight technology reduces molded fiber tooling costs

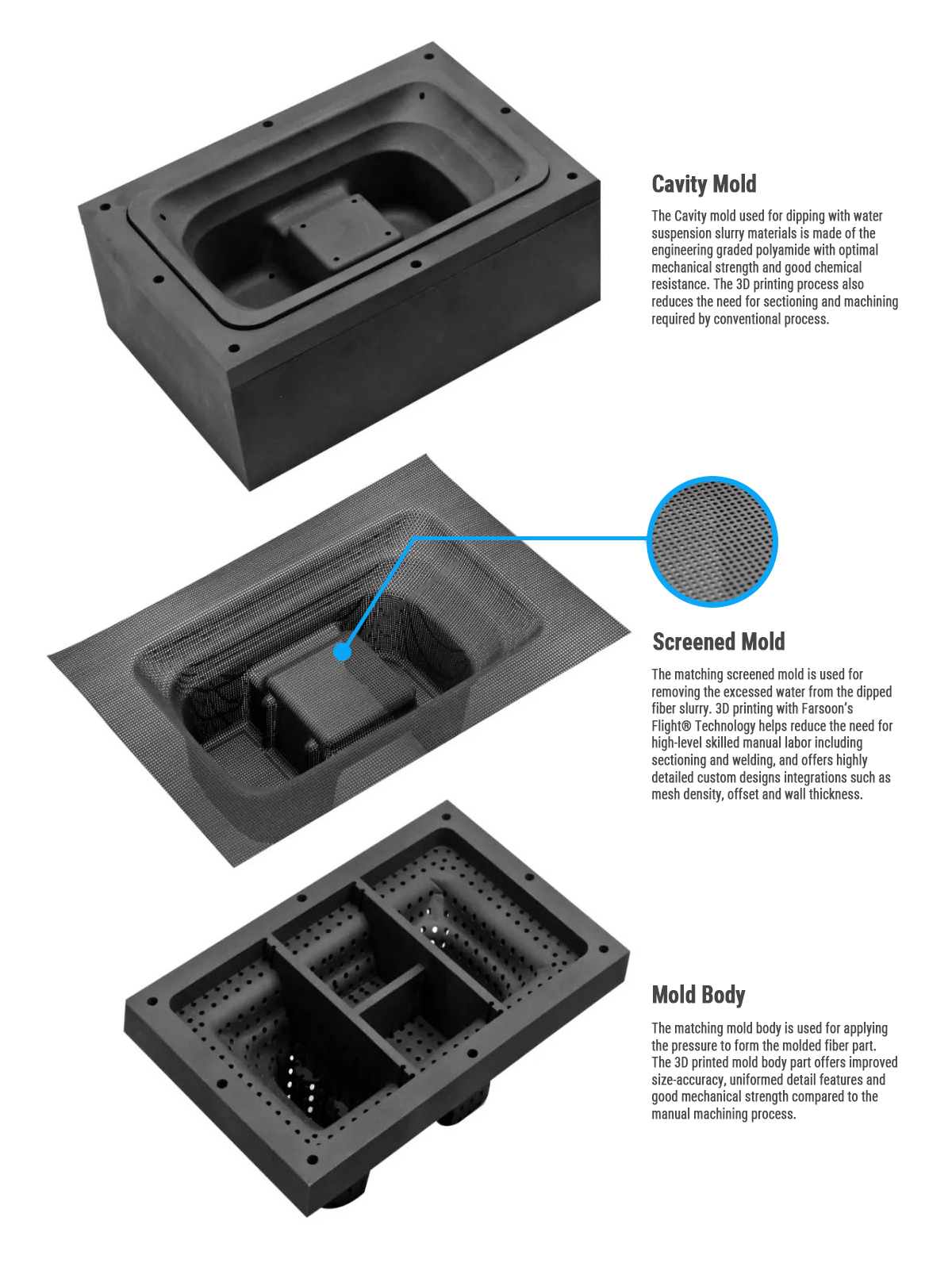

3D printer manufacturer Farsoon Technologies has revealed its Flight Technology has reduced molded fiber tooling costs for ERI Packaging, a manufacturer of customized molded fiber products, by 97 percent. Farsoon’s Flight Technology was deployed to produce a full mold tooling set for electronics packaging, including a mold body, a cavity mold, and a screened mold.

Farsoon’s technology was able to deliver improved feature detail compared to other plastic-based technologies, alongside better surface quality and fitting accuracy to the mold which in turn created a better, cleaner molded fiber pulp product. The technology also enabled faster design iteration, improved production yield, and better efficiency during the design and manufacturing process, proving the technology as an economic alternative for low volume production.

Ramping up the space race

This week’s round-up finishes with news from 3D printer manufacturer SLM Solutions, which has received an order for two of its NXG XII 600 3D printing systems from a leading California-based rocket company. With the purchase of the new systems, the unnamed rocket firm is seeking to make its space missions more affordable and efficient by creating lighter, faster, and more robust space parts.

“The NXG XII 600 is a true game-changer for the rapidly growing (New) Space industry,” said Dr Simon Merkt-Schippers. “Here, traditional space companies and established players must cope with strong growth and an urgent need for complex parts to win the modern space race. SLM Solutions technology enables more affordable missions due to smarter designs that make rocket engines more efficient, bringing their performance to the next level.

“There is probably no faster and more efficient way to explore orbit and come out triumphant than utilizing the capabilities of the NXG XII 600.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Usmih dental aligners with the Sliced logo.