In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a host of new 3D printer installations and applications, as well as ambitious expansions, engineering skill shortage research and a call for 3D bioprinting to put an end to animal testing in drug R&D.

Read on for the most recent updates from Massivit 3D, DesignPoint, Castheon, Objectify, Wematter, AM-Flow, PrintParts, NAFEMS, Brinter, NTU Singapore and more.

Turn of the year sees acquisitions galore

Starting our first roundup of 2022 with the latest in additive manufacturing’s business world, Hawk Ridge Systems has announced the purchase of fellow 3D printer reseller DesignPoint. Carried out as part of a wider initiative to expand the reach of Hawk Ridge’s services to clients across the Eastern United States, the firm anticipates that the acquisition will take its current customers to over 33,000.

“Our vision, values and business priorities are aligned,” said Dale Ford, President and CEO of Hawk Ridge Systems. “Not only do we share a common language of customer focus, but we have also been on the same journey with the evolution of our 3D design solutions with our partners at Dassault Systèmes SOLIDWORKS and Markforged.”

Middle-market manufacturing investor CORE Industrial Partners has also revealed that its subsidiary CGI Automated Manufacturing has bought both Precision Metal Fab and Precision Tool & Die. Known collectively as ‘PMF,’ the firms specialize in high-volume metal cutting and forming using their fleet of 10 and 15-kilowatt fiber-optic lasers, technologies that are thought to be complementary to CGI’s own.

“From state-of-the-art equipment to lights-out automation, we believe PMF is at the forefront of metal manufacturing technology and fits exceptionally well with the CGI platform,” said Matthew Puglisi of CORE Industrial Partners. “We look forward to leveraging the broader capabilities of CGI, PMF and AL to drive organic growth while continuing to pursue strategic acquisition opportunities.”

Likewise, CNC machining specialist Ellison Technologies has acquired 3D printing reseller and engineering service provider GSC. In doing so, the company expects to be able to grow the addressable market of its software and additive manufacturing offering across the US, thus allowing it to better “help customers achieve their business goals to an even higher degree than it does today.”

In the aerospace sector, meanwhile, ADDMAN Engineering has announced the takeover of orbital 3D printing specialist Castheon Inc. Given that its new subsidiary currently works with spacecraft companies to design, develop and 3D print complex parts, ADDMAN believes that its acquisition will now enable it to “transform thinking around component development” for its clientele with spacefaring ambitions.

Installations at Objectify, Wematter and more

Onto the most recent 3D printer installations now, and service bureau Objectify Technologies has bought and fitted an EOS Formiga P396 machine. Installed alongside its other Formiga P110 and P396 SLS systems, the unit is expected to allow the firm to reduce its downtime between builds, as well as ramping up its capacity to meet growing demand.

Similarly, Belgian 3D printing service provider ZiggZagg has installed AM-FLOW’s AM-VISION and AM-SORT systems at its facility in the town of Aalter. Through adopting the machines, the company says that it aims to “fully-automate [part] cleaning, post-treatment, identification, sorting, transport, packaging and labeling,” and ultimately establish an ‘Industry 4.0 Smart AM Factory.’

Moving forwards, the firms have also agreed to collaborate on developing a means of automatically routing and tracking all printed parts, providing Ziggzagg with an overview of every order that enables it to reduce its errors and associated costs.

Elsewhere, in South Korea, the Korean Institute of Industrial Technology or ‘KITECH,’ has announced the installation of Desktop Metal’s Shop Production P-1 platform. Using its new binder jet system, the organization intends to produce parts at industrial-scale, develop novel 3D printing materials, and drive their wider adoption by Korean automotive, consumer electronics, industrial and oil and gas SMEs.

“Metal binder jetting is ripe for adoption in Asia-Pacific, and we are honored to partner with KITECH to further scale the technology in South Korea,” said Ric Fulop, CEO of Desktop Metal. “The installation of these binder jet solutions will serve as a catalyst for innovation, development and commercialization of AM 2.0 technologies in the region, and accelerate the transformation of the manufacturing industry.”

Finally, on the machine-fitting front, Swedish 3D printer manufacturer Wematter has unveiled plans to invest 5 million Swedish Kronas into increasing its capacity. Citing a particular rise in demand for its Gravity SLS 3D printer, the firm has now committed to scaling as a means of ensuring that it continues to deliver parts to schedule, and it has already kickstarted the initiative by hiring five new colleagues.

“Demand is gradually increasing as a result of our sales and marketing efforts,” explained Wematter CEO Robert Kniola. “The next step is to scale up our production capacity, which we have done by investing in our team and our own facilities, which are more than doubling in size, leasing to a 1,500% increase in production capacity.”

PrintParts and Autentica unveil growth plans

Over the festive period, two fast-growing 3D printing firms also announced plans to significantly expand upon their respective operations. In the US, additive manufacturing service provider PrintParts has revealed that it intends to launch its ‘SmartParts’ beta program in Q1 2022, in which participants will be able to connect their material, hardware and software data to fully-track printed parts.

Earlier in 2021, the company began shipping SmartParts to select customers, and it’s now seeking further partners willing to collaborate with additional stakeholders such as material companies, machine OEMs, software providers and end-users, in order to help build what it describes as a “true end-to-end traceability solution” for manufacturers.

Any interested parties can can find out more about SmartParts’ beta program by contacting the firm directly at [email protected].

In the UK town of Blackpool, meanwhile, tech entrepreneur Irma Vitoriano and her husband George Gilbert have raised £158,000 to fund their AI-powered spare part supply chain business Autentica. According to a Gazette report, the pair attracted £58,000 from Innovate UK (which was later matched by investors), and they now aim to make 20 hires in a bid to become the “Amazon of the global AM sector.”

“Autentica exists to transform supply chains, reduce environmental impact, and build a sustainable future for the global additive manufacturing sector,” explained Vitoriano. “By providing a platform for the 3D printing of parts, we’ve created a global network of designers, manufacturers, and customers seeking a fast, efficient and streamlined experience.”

NAFEMS and BICO issue public calls

Independent engineering research organization NAFEMS has made a public call for abstracts to be presented at its Americas Regional Conference 2022. In particular, the group is seeking submissions that address the themes of simulation-driven design and simulation governance as well as advanced manufacturing and 3D printing processes.

Set to take place from June 21-23, 2022 in Indianapolis, the event itself is designed to bring together the developers and practitioners of CAE-related technologies, in an open forum to explore the issues of the day. Each session will include 3-4 presentations on relevant topics, with those presenting at the show expected to benefit from discounted registration fees in recognition of their participation.

Those interested in finding out more about the conference or submitting an abstract for discussion at the event, can do so here.

In a similar (albeit slightly different) call to action, 3D bioprinting firm BICO has also thrown its weight behind the FDA Modernization Act of 2021. If passed, the bill would allow US drug and cosmetic manufacturers to develop new products using cell-based models such as organ-on-a-chip devices instead of animal testing, bringing an end to what BICO calls an “ethical issue plaguing the life sciences industry.”

Citing bans introduced by other countries, the company now questions the efficacy of animal testing altogether, and says it plans “to actively build support for the legislation.”

“Human tissue replacement models are undoubtedly a better indicator of toxicity and efficacy than dogs or mice, which share very little physiology to humans,” explains Alex Armento, President of MatTek, a BICO group company. “By giving researchers the choice of testing on animals or human-models, we’ll ultimately enable them to make the best decision based on the science.”

Elsewhere, in other bioprinting-related news, Finnish start-up Brinter has established a partnership with LED Tailor, that has allowed it to integrate disinfecting blue light technology into its modular 3D bioprinter. In doing so, the firm is now able to provide its clientele with a way of more safely producing tissue models, while minimizing the need for separate cleanrooms, effectively making their workflow portable.

“Our photon disinfection innovation is an automatic and sustainable solution to microbe problems,” adds Harri Rautio, CEO of LED Tailor. “The system enables safe bioprinting, the production of food and beverages, restrains epidemics and answers the needs of cleanrooms.”

Medical advances at NTU Singapore and Formlabs

In medical 3D printing news, Nanyang Technological University Singapore has worked with the country’s Centre for Orthopaedics and Delsson, to 3D print 30% lighter knee braces. Designed to have a similar appearance to that used in Batman: The Dark Knight Rises, the team’s ‘X-Brace’ features a unique design that relies on light plastic and assistive springs to absorb the strains of wearers climbing stairs.

Having now perfected their device’s design, the team has now partnered with Delsson subsidiary Wearable Kinetics to bring it to market, where it’s expected to be available at a price of around $782 (USD) depending on user configuration.

Fabian Ong, Executive Director of Delsson Singapore said: “the X-Brace will be revolutionary for patient recovery. It is lightweight and does not slip, while its modular assistance load allows patient recovery to be individualized. NTU’s help in providing a quantitative methodology to reduce wall thickness and profile of the frame was crucial in achieving the weight reduction.”

Formlabs has also announced a significant healthcare breakthrough, in that it has become the first 3D printing company to become listed in a major group purchasing organization’s (GPO’s) catalog. Having gained a contract from medical insights firm Vizient, Formlabs’ products will now be offered to those seeking to create anatomical replicas across the company’s clinical supply network.

“The inclusion of the Formlabs technology ecosystem in the Vizient catalog signals an inflection point for 3D printing in the healthcare industry,” said Formlabs’ Gaurav Manchanda. “As the first 3D printing company to be listed in the largest and most prominent GPO catalog in the country, Formlabs has solidified its position as the leader driving adoption of 3D printing for precision surgery.”

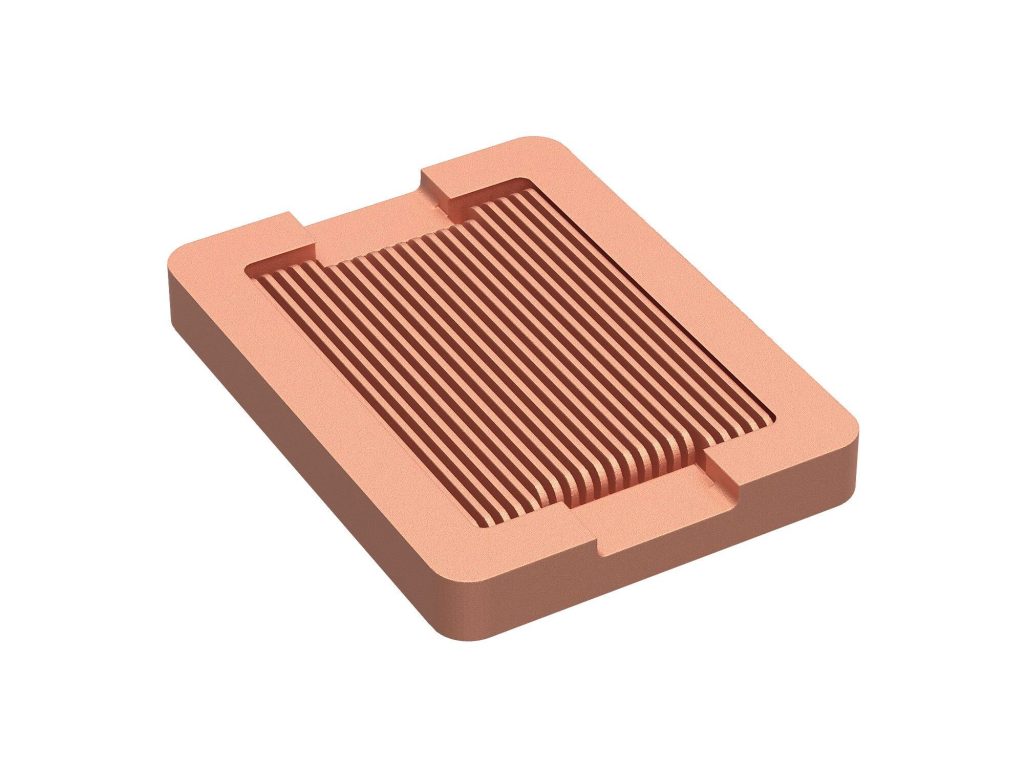

Desktop Metal qualifies pure copper

Industrial 3D printer manufacturer Desktop Metal has qualified copper of more than 99.95% purity on its Production System for the first time. In doing so, the firm has effectively come up with a means of using its Single Pass Jetting process to create new high heat-transfer parts such as cold plates, pucks or manifolds from the alloy, lending its systems novel automotive, aerospace and electronics applications.

“Copper has been a highly requested material from many of our customers and prospects, and has applications spanning a broad variety of industries,” said Jonah Myerberg, CTO of Desktop Metal. “We are excited to be able to expand our extensive Production System materials portfolio to support customers looking to 3D print electrically and thermally conductive components at scale.”

Photocentric, Massivit 3D break new ground

UK-based LCD 3D printer manufacturer Photocentric has revealed that its technologies are being deployed within a new industry: the industrial vacuum cleaning space. In the hands of customer Dustless Technologies, the firm’s printers are now being used to iterate upcoming products and produce part tooling in a way that drastically reduces its upfront costs.

“We’re still looking for that sweet spot for a printer that will print even larger parts, but we see it as the future,” said Spencer Loveless, CEO of Dustless Technologies. “We realize that we may be on the bleeding edge of technology, but we were willing to take the risk to dive into this. A lot of industries I talked to said we were 10 years ahead of our time and that just put a fire under me to make this work.”

“As time goes on and technology improves, we will be ahead of the game compared to everyone else.”

Israeli 3D printer manufacturer Massivit 3D has also announced an expansion into a new market, after signing a strategic collaboration agreement with Kanfit. The companies’ deal will see Kanfit install Massivit’s 10000 3D printer at one of its plants, which is set to serve as a beta site for the new machine. While the nature of these tests has yet to be revealed, Kanfit is known to produce parts and assemblies for the likes of Israel Aerospace Industries and Elbit Systems, amongst others.

Massivit CEO, Erez Zimerman, said: “We are excited to sign the first agreement of this kind, for the strategic collaboration with Kanfit – one of the most important defense manufacturers in Israel. This agreement is a momentous milestone in achieving Massivit’s goals and business strategy.”

UK research identifies engineering demand

Finishing this week with the UK Department of Education, the government office has published a report, indicating that there’s a growing demand for those with engineering or manufacturing qualifications. To help meet this skill shortage, the department has called for relevant professionals to share their experience, by becoming teachers in Further Education. Helen Tupper, CEO of career coaching firm Amazing If, has emphasized that doing so could prove to be mutually beneficial.

“Deciding to teach your current profession by including Further Education teaching as part of a portfolio career is an excellent way to make the most of existing expertise whilst trying something new,” explained Tupper. “It can also increase people’s sense of purpose, increasing their happiness at work over the long-term.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on top of the Centre for Orthopaedics’ Chairman & CEO Dr Jeffery Chew helping one of his patients to wear NTU Singapore’s X-Brace. Image via NTU Singapore.