In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition covers everything from 3D printed bobsled helmets to name badges, with updates on industry education initiatives, system installations, rebranding exercises, trade shows and even an amphibious trike along the way.

Read on for updates from MakerBot, Fluicell, ETEC, Zortrax, SPEE3D, Additive Industries, Photocentric, Kingsbury, the FDA, Formnext and more.

Zortrax and SLM Solutions roll-out software updates

Starting this week’s round-up with the latest software updates, Polish 3D printer manufacturer Zortrax has launched a new version of its Z-SUITE software. Known as ‘BETA 3.0,’ the updated program’s headline addition is ‘multiple contour’ functionality, a feature designed to provide users with greater control over the mechanical strength and dimensional accuracy of 3D printed objects.

The new Z-SUITE also allows adopters to choose from a wider range of infill patterns, including gyroid, triangle and concentric shapes, as a means of modulating the resistance characteristics of parts produced, in addition to improved seam control, as they can now be placed in specific areas of the model, without this affecting a print’s aesthetics.

Those interested in beta testing Z-SUITE BETA 3.0 can install the program via Zortrax’s ‘downloads’ section here.

German 3D printer manufacturer SLM Solutions has also launched a new software, albeit one focused more on quality assurance than modeling. Designed to enable manufacturers to more effectively carry out job evaluation, process qualification and part certification, the SLM.Quality program is said to be perfect for improving traceability and compliance, especially among automotive and aerospace users.

“SLM.Quality is the ideal quality assurance solution to enable additive manufacturers to adopt the best-in-class industry practices,” said Nicolas Lemaire, Product Manager Software & Product Control at SLM Solutions. “The solution is flexible, as we offer a ready-to-use desktop application with visualization dashboards and a reporting tool, but also an API to enable seamless access to the process data for the MES and Production control system.”

SPEE3D wins inaugural US military award

Elsewhere, in the world of military additive manufacturing, metal 3D printer developer SPEE3D has won the first-ever Expeditionary & Tactical 3D Printing Excellence Award. Handed out by the US Defense Strategies Institute, organizers of the annual Military Additive Manufacturing Summit, the prize was awarded in recognition of its technology’s contribution to furthering the USA’s defensive capabilities.

“We had an incredible number of entries this year from various esteemed governments, the defense industry and defense prime organizations based in the US, and internationally,” said Richard Giordano, Director of Programs at the Defense Strategies Institute. “We would like to congratulate all of the recipients making waves in the advanced manufacturing space to improve [the US’] sovereign defense capabilities.”

“The 3D Printing Awards is dedicated to recognizing individuals, or groups, that have exemplified an outstanding achievement in 3D printing in support of DoD mission priorities.”

New applications from Farsoon, Additive Industries and more

Moving onto the latest applications now, Dutch metal 3D printer manufacturer Additive Industries has revealed that high-end turbocharger developer ABB Turbocharging has adopted its MetalFAB1 platform. Using its newly-installed system, the firm has begun producing spares for its 500 kW to 80+ MW turbochargers, in a way that reduces their lead times from nine weeks to less than one.

In the UK, meanwhile, engineering firm Kingsbury has demonstrated the efficacy of partner GEFERTEC’s wire arc additive manufacturing WAAM technology, by 3D printing an Inconel engine blisk. Using the machine, composed of a 5-axis machine tool platform controlled by a Siemens 840D CNC system, the firm has managed to deposit Inconel 625 directly onto a 300 mm-diameter central hub.

Traditionally, doing so would’ve required the use of forging and milling, in a process costing in excess of £3,500, but leveraging GEFERTEC’s technology, Kingsbury was able to achieve this for £1,764. The resulting part also weighed in at 27.8 kg, 37.5 kg lighter than it would be if built via subtractive manufacturing, while being ready within 9.5 hours, significantly faster than the months it’d normally take to produce.

Elsewhere in Britain, name badge manufacturer Badgemaster has adopted Photocentric 3D printing as a means of pivoting its production process in time for a major client rebrand launch. By additive manufacturing products that were previously-tooled and molded, the firm is said to have been able to produce the 30,000 components it needed using LC Magna systems, inside of three weeks.

Fittingly, with the Winter Olympics still well underway, Chinese 3D printer manufacturer Farsoon has also unveiled a new application of its technology: the creation of latticed bobsled helmets. Honed alongside the Dongguan University of Technology’s Professor Li Nan and the Wanhua Chemical Group, the TPU headwear is said to provide “superb performance” even under “extreme temperatures.”

“Thanks to Farsoon’s high-speed dual-laser Flight Technology, we have been able to achieve a customized design and accelerate the manufacturing process,” explains Li. “We are also impressed with the performance of the new generation of customized helmets, as the impact strength of the helmet lining is increased over 40% compared with the international standard.”

“It’s inspiring for us, to use 3D printed lattice structures to produce other protective sports pieces, which brings new opportunities for the upgrading of helmets, armors and other protective equipment.”

Finally in this week’s application update, Italian design studio EGO.M has used FDM 3D printing to modernize a set of historic calligraphy tools. Since being dscovered in the home of legendary designer Achille Castiglioni, the non-functional prototypes have been labeled one of his ‘last projects’ before he passed in 2002.

Working with architect Gianfranco Cavaglià and the Fondazione Achille Castiglioni, the firm has now managed to 3D print a renovated set of this art equipment, for Castiglioni’s children Giovanna and Carlo. Named ‘CENTO3,’ the collection, composed of a mechanical pencil, multifunctional art pencil and pocket fountain pen, are not only said to be faithful to the original designs, but function as intended.

America Makes, Stratasys in educational initiatives

US 3D printing accelerator America Makes has announced a collaboration with the Educational Service Center of Eastern Ohio, in which it aims to get Mahoning Valley pupils into advanced manufacturing. As part of the partnership, the students have not only gotten to tour America Makes’ Boardman Street center, but they’re set to benefit from a syllabus being developed to give them industry-standard qualifications.

“We know there’s a skills gap in advanced manufacturing,” explains Josh Cramer, Education and Workforce Development Director at America Makes. “To tackle that, we have to work on both sides of that. We need to inspire and create awareness in youth and their parents to enter these pathways.”

In a similarly educationally-inspiring move, 3D printer manufacturer Stratasys has also begun sponsoring the University of Minnesota’s Visible Heart Labs. As part of the deal, the company has donated Stratasys J750 Digital Anatomy, MakerBot METHOD X and MakerBot SKETCH 3D printers to the facility, where they’ll be used to support medical research, student education and product R&D.

“We believe that widespread use of 3D printed anatomical models in healthcare would translate into better and more cost-effective patient care and shorter time to market for new medical device innovations,” said Rich Garrity, President, Americas for Stratasys. “At Stratasys, we recognize the importance of supporting the communities in which we live and work, and we are proud to support the University of Minnesota Visible Heart Laboratories and the work they are doing.”

“This sponsorship allows us to support the world-class education and medical device research happening right here in Minnesota.”

Desktop Metal rebrands envisionTEC

In this week’s short but sweet business update, 3D printer manufacturer Desktop Metal has announced the rebranding of its envisionTEC subsidiary. Now known as ETEC (apparently pronounced ē-tek), the DLP system developer’s logo has also changed to one that’s designed to look like one of its 3D printer’s build trays, but it remains firmly committed to the field of high-speed photopolymer machines.

“Our launch of ETEC and Desktop Health allows us to speak more directly to specific customers with focused needs and serve them better,” explains Ric Fulop, CEO of Desktop Metal. “ETEC offers incredibly powerful 3D printers paired with exclusive materials that are already driving a new wave of consumer and industrial innovation.”

“Desktop Metal’s integration strategy is to focus on customers and their application needs first, so we can craft the most personalized and compelling business case for them to adopt additive manufacturing 2.0 technologies.”

New system installations and launches announced

Onto machine fitting and launch news now, and bioprinter manufacturer Fluicell has teased the upcoming release of its Biopixlar AER platform. Set for launch on March 3, 2022, the system is expected to be ultra-compact, single cell-resolution capable, and packed with portability and automation features, in a way that could make it ideal for use in demanding aerospace or deep-sea exploration settings.

“The AER showcases a wide range of powerful features tailored for today’s laboratory environment,” says Fluicell CTO Gavin Jeffries. “A deep integration of fluidic, optical and motion control, combined with a small footprint and process automation, is designed to empower researchers with bioprinting tools in demanding environments.”

Elsewhere, GF Additive Novazzano’s AMotion Center has announced the installation of a new 3D Systems DMP Factory 500 3D printer. Fitting the system at its complex in the Swiss municipality of Stabio, has provided the company with Inconel 625, Alloy X and Inconel 718 3D printing capabilities for the first time, thus it’s now able to better meet demand from its clients for corrosion and heat-resistant parts.

Finally, in system adoption news, Raytheon Technologies subsidiary Collins Aerospace has announced plans to install an SLM Solutions large-format 12-laser NXG XII 600 3D printer at its engine nozzle facility in Iowa. Once delivered in H2 2022, the machine is expected to add to its existing SLM portfolio, and help ramp up the production and innovation of the firm’s additively manufactured aerospace parts.

“Collins Aerospace and SLM Solutions have been operating several SLM Solutions machines in different locations around the globe for a number of years now,” said Gerhard Bierleutgeb, Executive VP of Global Services and Solutions at SLM Solutions. “The procurement of the latest generation NXG XII 600 shows that both parties have successfully managed to service and operate this technology in an aerospace production environment.”

MakerBot, FDA and White House research comes to fruition

Kicking off this week’s research update with MakerBot, the Stratasys subsidiary has released its annual State of 3D Printing report, along with some fascinating findings. Despite the impact of COVID-19 and shipping disruption over the last year, the firm’s research has shown that 74% of those interviewed in 2021, intended to make a new investment in the technology, and 84% plan to do so again in 2022.

While 67% of those expecting to buy more 3D printing equipment this year anticipated deploying it within R&D, 45% planned to use it within short-run production, and 39% hope to leverage it to avoid supply chain disruption. Interestingly, 13% of all respondents said they would also be spending upwards of $10,000 on such gear in the coming year, with 81% of these firms targeting brand new applications.

Those interested in reading MakerBot’s full State of 3D Printing 2022 report can do so here.

Over in the medical field, the American College of Radiology (ACR) has provided some feedback to the FDA, after the organization called for comment on the regulation of clinical 3D printing late last year. In its recommendations, the ACR has requested that the FDA “exercise enforcement discretion,” when it comes to the additive manufacturing of what it calls “low-risk” parts like surgical models.

The group is also calling for FDA to use the term “healthcare” instead of “point of care” to describe 3D printing facilities, as according to ACR Chair Dr. Howard Fleishon, the systems are very rarely deployed at patients’ bedsides,

“A [healthcare facility] performing the printing could serve in a traditional manufacturer-type capacity to a disparate [healthcare facility],” said Fleishon. “Therefore, some delineation between [healthcare facilities] that create the device and [healthcare facilities] that use the device may be necessary if separate entities, but without using ‘[point of care]’ as the descriptor.”

Lastly in our research review, US 3D printing accelerator America Makes has issued a statement, hailing the White House’s inclusion of additive manufacturing within its updated list of critical and emerging technologies. The organization says that 3D printing’s inclusion on the list shows that the US government “continues to see investment in the emergence of AM technologies as a high priority.”

“We applaud the White House for including AM on the updated list of critical and emerging technologies, compiled by the US Office of Science and Technology Policy,” said America Makes. “The inclusion of AM shows that additive is playing an important role in helping increase US manufacturing competitiveness and meeting national security needs.”

Formnext 2022 approaches capacity

Mesago Messe Frankfurt, organizer of the annual Formnext 3D printing trade show, has announced its best ever start to a year. Having already registered over 300 industry-leading exhibitors, including the likes of EOS, 3D Systems and Stratasys, the group says that total floorspace at the event is now “almost fully-booked.”

“We have never had such a large number of registrations at such an early stage in the year,” says Sascha F. Wenzler, VP Formnext at organizer Mesago Messe Frankfurt. “This successful development shows that exhibitors continue to see Formnext as the most important industry meeting point and an extremely valuable trade show platform, and allows us to look forward to a successful Formnext 2022 with a great deal of confidence.”

Companies interested in showcasing at the conference can still benefit from a discount of 17% until 31 March, 2022, with further information available here.

$15,000 amphibious camper-trike goes on sale

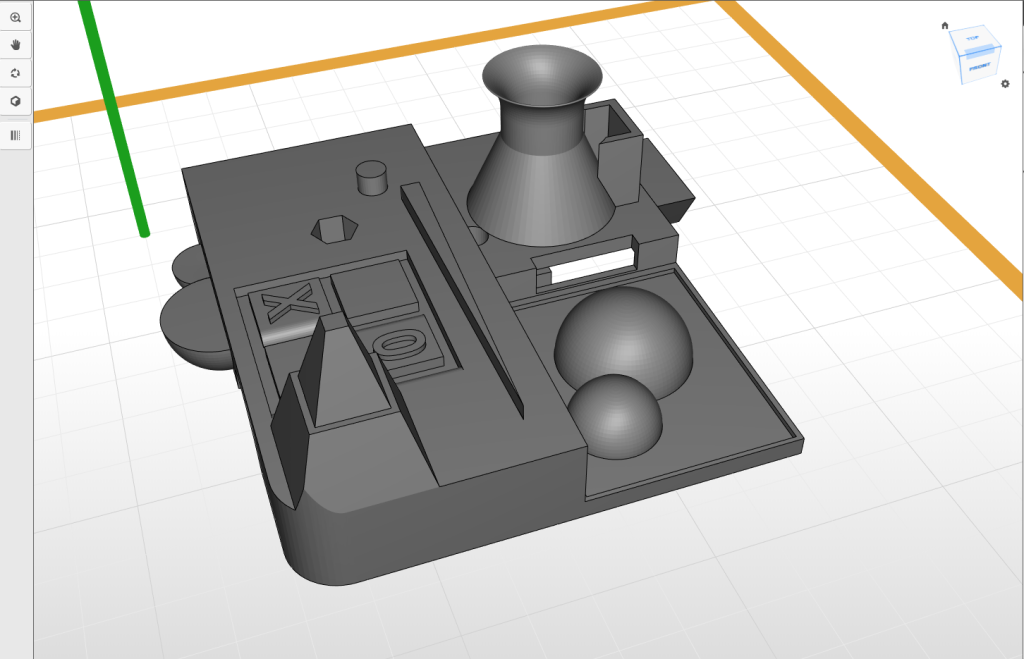

Rounding off this week’s update with Zeltini, the Latvian design studio has launched an integrated tricycle, boat and camper van with a partially-3D printed body that has the potential to revolutionize camping holidays around the world.

Featuring an organic fiberglass and polyester hull, composed of several large-format additive manufactured bioplastic parts, the Z-Triton 2.0 e-trike is now available for $15,000, or around $5,100 for the build-it-at-home version. The amphibious camper-trike, which has been tested in the Swiss Alps, Paris, Amsterdam and Berlin, can be seen in-action below.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Zeltini’s partially-3D printed ‘Z-Triton 2.0’ amphibious camper-trike with the Sliced logo on it. Image via Zeltini.