In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new materials, partnerships, and business deals, and Balena and designer Kitty Shukman crafting compostable 3D printed slide.

Read on for the most recent updates from IperionX, Boston Micro Fabrication, 3YOURMIND, Tri-Tech 3D, and more.

Don’t forget to make your nominations for the 2023 3D Printing Industry Awards, the deadline is approaching fast.

Business deals and acquisitions from IperionX, Sigma Additive Solutions, AML3D, and more

Diving into business deals and acquisitions, IperionX has announced an agreement with the U.S. Army Combat Capabilities Development Command Ground Vehicle Systems Center (DEVCOM GVSC) to evaluate the ballistic testing properties of their high-strength titanium plate components. DEVCOM GVSC may share the results with key U.S. Department of Defense (DoD) contractors, including General Dynamics Land Systems, BAE Systems, American Rheinmetall Defense, Oshkosh Corporation, and AM General, for potential integration into future U.S. Army ground vehicle designs. IperionX will utilize powder metallurgy and its advanced titanium angular powder, along with patented Hydrogen Sintering and Phase Transformation (HSPT) technologies, to manufacture the titanium plates, enhancing their performance and durability. This collaboration aligns with the DoD’s efforts to reduce reliance on foreign titanium imports and establish a self-sustaining, efficient domestic titanium supply chain for critical defense systems.

“We are honored to collaborate with DEVCOM GVSC to evaluate our titanium products for U.S. Army ground vehicles. Titanium for the U.S. defense sector is currently sourced over long distances from foreign nations. IperionX plans to re-shore a lower cost and more sustainable fully integrated U.S. titanium supply chain that is critical to America’s economic future and national security,” said Anastasios (Taso) Arima, IperionX CEO.

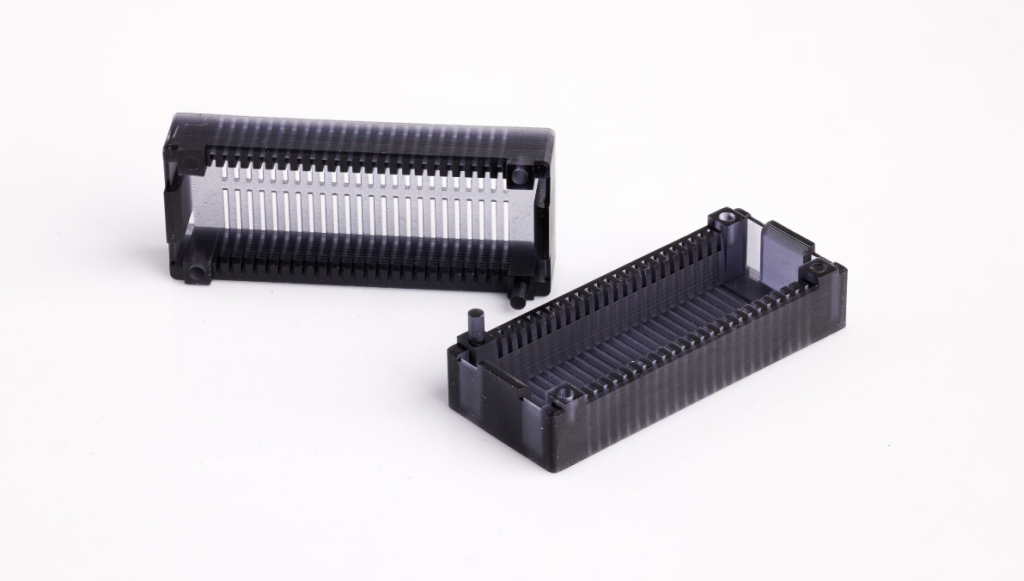

Followed by Boston Micro Fabrication (BMF) has qualified Mechnano’s Formula1µ resin for its 10 micron S240 printers and the latest 25 micron microArch S350 3D printer platform. Formula1µ is a static-dissipative resin ideal for fast and affordable part fabrication in sub-90°C environments. Researchers and manufacturers can now create prototypes, manufacturing aids, and end-use parts with electrostatic dissipative (ESD) properties. Mechnano’s Formula1µ is based on proprietary Carbon Nanotube technology, ensuring high resolution and isotropic properties.

Sigma Additive Solutions has announced the acquisition of NextTrip, a travel technology company, through a non-binding letter of intent (LOI). The deal involves Sigma Additive Solutions issuing shares initially constituting 19.99% of its common stock, with additional shares tied to NextTrip’s performance milestones, valuing the transaction at around $48 million. This move positions NextTrip for a Nasdaq listing. Concurrently, Sigma has signed an LOI to sell intellectual property assets related to its additive quality assurance product. These strategic actions aim to enhance shareholder value, with NextTrip poised to leverage its status as a public company for capital and growth opportunities.

Global manufacturing marketplace Xometry‘s Thomas has introduced “Build America, Buy America” (BABA) certification to its directory, Thomasnet.com, featuring over 500,000 suppliers. Domestic manufacturers can now signal their adherence to the BABA initiative, a critical part of the Infrastructure Investment and Jobs Act (IIJA). BABA mandates federally funded infrastructure projects to source U.S.-made materials and products. Xometry aims to strengthen the domestic supply chain by facilitating connections between major companies and BABA-compliant suppliers, supporting American manufacturers and the U.S. economy. Suppliers can easily declare their BABA compliance on Thomasnet.com, North America’s largest industrial sourcing platform with nearly 500,000 U.S.-based suppliers.

“Our aim is to help major companies seamlessly connect with BABA-compliant suppliers to further strengthen our domestic supply chain and provide continued support to American manufacturers,” said Randy Altschuler, CEO of Xometry, parent company to Thomas. “America’s 600,000 small- and mid-size manufacturers are the backbone of our domestic economy and are deeply ingrained in their communities. Supporting them is a win for the American worker, for our neighbors and for our country.”

Australian large-format 3D printer manufacturer AML3D has secured its first order for a 2600 Edition ARCEMY system from Laser Welding Solutions (LWS), positioning LWS as a supplier of Nickel Aluminum Bronze (NAB) components to the US Navy’s Submarine Industrial base. The ARCEMY system, AML3D’s smallest industrial-scale metal 3D printer, will produce NAB components tailored for US Navy applications. The 12-month lease, valued at approximately A$0.27 million (US$0.22 million), includes software licensing and technical support. LWS can opt to purchase the system at any time during the lease or it will be available for redeployment to further support AML3D’s US scale-up strategy. This move aims to expedite LWS’ entry into ARCEMY production, with the system set to operate in Houston, Texas, within 8 to 10 weeks. The agreement supports AML3D’s strategy of embedding ARCEMY systems within US Navy suppliers as part of its US scale-up efforts in the thriving additive manufacturing market.

Global standards organization ASTM International has inked a memorandum of understanding (MoU) with South Korea’s 3D Fusion Industry Association (3DFIA). The agreement was formalized during the 10th ASTM International Additive Manufacturing Center of Excellence (AM CoE) Snapshot Workshop, co-hosted with 3DFIA. Held in Incheon, South Korea, and coinciding with ASTM F42/ISO TC261 joint meetings, the workshop convened industry leaders and experts. Dr. Mohsen Seifi, ASTM International’s VP of global advanced manufacturing programs, and Chungwon Park, 3DFIA president, signed the MoU. It encompasses training, research projects, and advisory services to bolster international collaboration between ASTM and South Korea’s AM industry.

whatt.io Inc, originating from Lostboyslab, has joined the 3MF Consortium as an associate member. With expertise in additive manufacturing and micro-factory operations, whatt.io aims to advance digital production. The 3MF (3D Manufacturing Format) is an open-source file format designed for future manufacturing, ensuring precise 3D model descriptions and overcoming limitations of traditional formats. The 3MF Consortium, a collaboration of industry leaders, works to establish a universal, high-fidelity format for 3D printing and digital manufacturing. whatt.io’s goal is to enhance digital product passport solutions, particularly for spare parts. It is introducing the ‘3MF Vault’ solution, transitioning from Proof of Concept to a fully integrated SaaS solution, expanding 3MF format capabilities with metadata inclusion, like copyright and ownership details.

“With 3MF, we are presented with more expansive opportunities to protect the intellectual property and copyrights of digital production files. This stands as one of the most formidable challenges in the path of digital manufacturing’s evolution,” says Founder and CEO, Stefan Larsson for whatt.io.

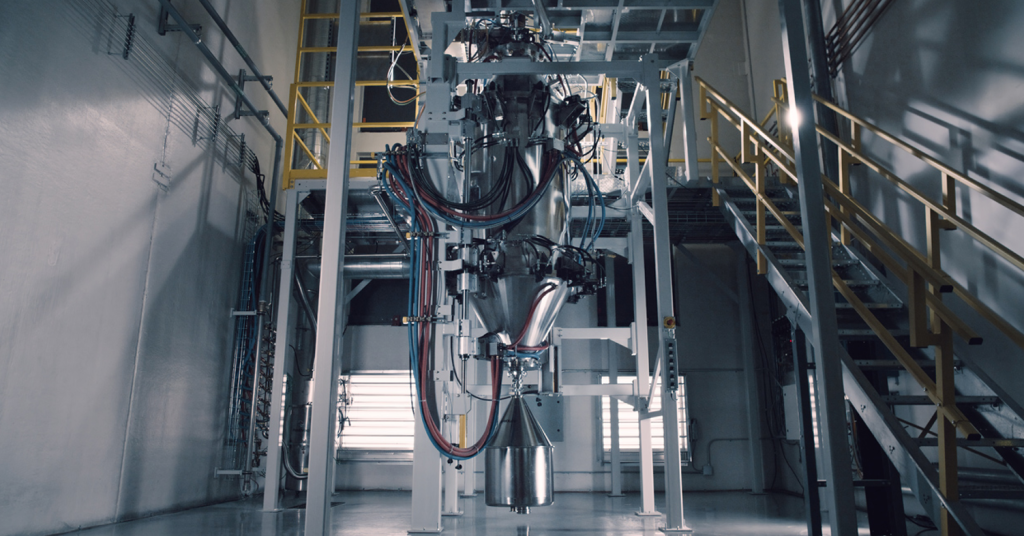

Furthermore, 6K Additive, a subsidiary of 6K, has secured a 5-year Blanket Purchase Agreement (BPA) from the Army Contracting Command in support of the US Army Development Command (DEVCOM). This BPA will bolster weapons R&D efforts at DEVCOM, catering to the growing demand for prototypes and low-rate initial production (LRIP). The agreement covers entities at multiple locations, including Picatinny Arsenal in NJ, Benet Labs in NY, Adelphi Laboratories in MD, and Rock Island Arsenal in IL. 6K Additive employs its proprietary UniMelt microwave plasma platform to produce metal powders, enabling the transformation of high-value metal scrap into aerospace-grade powders, including strategically vital metals such as nickel and titanium. This sustainable domestic supply ensures material security, quality, and consistency for the US military while expediting advanced systems development and cost management.

Emerging partnerships from 3YOURMIND, Koenigsegg Automotive, Black Buffalo 3D, and more

Now proceeding with partnership news, 3D printing software developer 3YOURMIND and Phillips Corp. Federal Division have announced their partnership with Marine Corps System Command’s Advanced Manufacturing Operations Cell (AMOC) to enhance digital additive manufacturing capabilities. They plan to integrate 3YOURMIND’s part identification software with the Digital Manufacturing Data Vault (DMDV), a central repository for Marine Corps data and designs, with the goal of improving AMOC’s operations. This collaboration aims to streamline the approval of spare parts for field use, aligning with the DoD’s mission to strengthen supply chains and leverage additive technologies for legacy equipment sustainability. Following a successful first-year contract, the $2.5 million AMOC award marks the continuation of their journey.

Next up, Additive manufacturing service provider BEAMIT SpA, and Constellium, a global leader in aluminum solutions, have signed a letter of intent to collaborate on advanced aluminum solutions. This partnership aims to leverage their expertise in additive manufacturing and aluminum across various industries. Their joint efforts will focus on extensive research and development to enhance aluminum properties for additive manufacturing processes. BEAMIT’s additive manufacturing proficiency, combined with Constellium’s alloy knowledge, will expedite the development and commercialization of advanced aluminum solutions. This collaboration seeks to meet the demand for lightweight, high-strength materials while prioritizing sustainability through aluminum’s recyclability and lightweight properties, marking a milestone in additive manufacturing’s evolution.

“We are thrilled to partner with Constellium, a recognized global leader in aluminium solutions, to advance the development of advanced aluminium materials for additive manufacturing,” said Gabriele Rizzi, General Manager of BEAMIT SpA. “By combining our additive manufacturing expertise with Constellium’s deep knowledge of aluminium alloys, we aim to deliver groundbreaking solutions that will enable new possibilities in a wide range of industries.”

Swedish sports car manufacturer Koenigsegg Automotive has enhanced its 3D printing processes and printer management by integrating the cloud-based 3DPrinterOS platform. The company has seen substantial growth in its 3D printer count, totaling 17 machines, including 11 FDM printers and various resin-based printers, over the past 2.5 years. 3DPrinterOS offers versatility, allowing engineers to seamlessly switch between different printer types for specific tasks, improving efficiency and quality. Real-time monitoring and centralized management have also boosted productivity and profitability, optimizing Koenigsegg’s 3D printing activities, with key contributions from experts Tim Bäck and Kristian Ljungkvist.

Construction 3D printing company Black Buffalo 3D has entered a MoU with Saudi Readymix Concrete Co., producer of ready-mix products in Saudi Arabia. The collaboration aims to manufacture Black Buffalo 3D’s proprietary structural ink using local materials and develop regional 3D construction printing materials, mixes, and additional ink formulas. By partnering with Saudi Readymix, Black Buffalo 3D intends to create reliable, sustainable, and locally produced ink for 3D construction printers. This ink will be used in the region to print housing, commercial buildings, and infrastructure components, with a focus on meeting local building code standards to promote adoption in Saudi Arabia. The regional distribution partner, Presidio Advisors in Dubai, will provide additional support to qualified builders.

“We are extremely proud to announce the signing of an MoU with the Black Buffalo 3D and to manufacture proven materials to further adoption and advancement of 3D printers to build homes, buildings and needed infrastructure throughout the Kingdom of Saudi Arabia,” stated Chris Leptokaridis, Technical & Strategy Director of Saudi Readymix Concrete Co.

Specialty chemicals company Evonik and LEHVOSS Group, a chemical and mineral specialties group, have joined forces in industrial 3D printing. LEHVOSS will develop its 3D printing formulations using Evonik’s PA613 polymer chemistry under the LUVOSINT brand. It will incorporate Evonik’s INFINAM PA 6005 P (PA613) polymer powder into their product range. This collaboration aims to unlock new automotive sector applications. INFINAM PA 6005 P, based on polyamide 613, suits 3D applications in higher-temperature settings and features low water absorption, enhancing processability and dimensional stability. LEHVOSS now offers both unreinforced and carbon-fiber-reinforced variants from a single source in their LUVOSINT product lines, tailored to diverse 3D printing processes.

Additionally, 6K Energy and Forge Nano have signed a five-year purchase and supply agreement for 6K Energy’s domestically produced NMC 811 cathode active material (CAM), which Forge Nano will use for battery cell production. This partnership aims to supply battery cells for various applications, including the DoD, aerospace, and fleet operations. 6K Energy’s NMC 811 will be produced at its PlusCAM factory, a sustainable, multi-chemistry battery material manufacturing plant set to open in late 2024. This facility will benefit from 6K’s UniMelt microwave plasma technology, known for its sustainability and reduced environmental impact compared to traditional methods.

“The Inflation Reduction Act’s goal of securing America’s position as a world leader in domestic clean energy manufacturing relies heavily on our nation’s ability to supply lithium-ion batteries on US soil. This agreement is a critical first step for our industry and one which we believe will strengthen domestic supply chains for lithium-ion battery production in the United States,” said 6K Energy President Sam Trinch. “Both organizations are keenly focused on delivering a 100% domestic supply chain for lithium-ion batteries to eliminate the dependence on foreign sources.”

Polish startup GREENFILL3D has partnered with COLORISED, an interior design platform, to create a distinctive line of lamps called ECO Lamps. These lamps boast unique shapes and colors and are crafted from biodegradable and compostable materials, including polylactide, polylactide infused with wheat bran, and fully compostable thermoplastic starch. ECO Lamps are biodegradable under industrial conditions and can be composted at home. They are produced using certified bioplastics from leading Polish companies. The lamps are grouped into two categories: Kolora Spektro and Brilanta Brano, each offering a range of colors and patterns, and come with color-matched fabric-coated power cables and LED bulbs.

New materials from Tri-Tech 3D, Carbon, and more

Followed by materials news, UK Stratasys 3D printing solutions provider, Tri-Tech 3D, is offering Polyamide (PA) 12 as a Selective Absorption Fusion (SAF) material. PA12 is a versatile polymer ideal for various applications, including consumer goods, automotive parts, and machinery components. It offers cost-effective production with improved thermal control, leading to better part consistency and intricate geometries. Users can efficiently nest end-use parts, resulting in lower costs and faster turnaround for higher-volume production. It also provides fine feature resolution, making it suitable for creating strong, functional, and precise components. PA12 is compatible with the Stratasys H350 3D Printer, offering industrial-grade SAF technology for accurate, consistent, and high-production-rate output.

“After listening to feedback about PA11 from users, its great to see that users now have access to the best powder bed material on the market,” explained Robert Pitts, sales manager at Tri-Tech 3D. “Its thermal control and chemical stability improves part consistency, making it viable for a range of applications both for prototyping and mass production, including complex end-use parts, manufacturing aids and automotive parts.

US 3D printer OEM Carbon has unveiled its latest elastomer material, EPU 46. This versatile material offers high-performance properties, superior durability, and a wide array of color options, making it ideal for creating premium products like saddles, footwear, and grips. EPU 46 is designed to meet diverse industry demands, emphasizing performance, comfort, aesthetics, and more. It allows for material stiffness adjustments without compromising printability or inherent properties. Furthermore, EPU 46 contributes to Carbon’s sustainability efforts, containing 40% bio-based material and designed for solvent-free spin cleaning and resin reclaim to minimize waste. This elastomer combines speed, customization, color fastness, and increased stiffness options, making it suitable for various applications.

AMALLOY, an aluminum alloy powder developed by the Technology Innovation Institute (TII) for additive manufacturing, debuted at the AM Conclave conference in Abu Dhabi. This Middle Eastern-designed metal feedstock is optimized for laser beam powder bed fusion (PBF-LB) systems, offering cost-effectiveness and high strength with excellent printability. Compared to commercial AlSi10Mg alloys, AMALLOY provides a 33% strength increase while maintaining ductility. Its unique chemical composition and metallurgical properties result in low susceptibility to hot cracking, enabling higher strengths without cracking. Further developments and applications are underway, emphasizing versatility across industries.

Depowdering technology specialist Solukon has introduced an automated powder collection unit for efficient and safe handling of excess powder after depowdering processes, particularly in larger systems and serial production like the SFM-AT1000-S. The Solukon Powder Collection Unit (SFM-PCU) uses an integrated vacuum conveyor system to transport excess powder to a large container, improving efficiency and safety. Users no longer need direct contact with the powder during depowdering, enhancing occupational health and safety compliance. The vacuum conveyor comes from Piab, a trusted partner for Solukon’s powder conveyors. Solukon is showcasing the SFM-PCU at Formnext 2023, highlighting its potential for large parts and automated serial production.

Financials news from Forward AM, and Xi’an Bright Laser Technologies

In H1 2023, Forward AM, a subsidiary of BASF, has experienced substantial growth, achieving a 39% increase in performance and a 51% rise in material business in its continuous portfolio compared to H1 2022. This robust performance aligns with a projected 19% compound annual growth rate (CAGR) for the 3D printing industry in 2023. Forward AM emphasizes collaborative industry partnerships to enhance customer value through novel materials, applications, and processes while addressing global market needs. Offering over 800 machine/material combinations, Forward AM stands as the premier independent provider of comprehensive materials and solutions. Their focus on ecological sustainability complements their long-term strategy, emphasizing profitability and sustainability through process optimization. In H2 2023, Forward AM continues its commitment to promoting AM adoption across industries, delivering superior materials and services.

Xi’an Bright Laser Technologies (BLT) has reported strong financial results for H1 2023, showcasing its growing demand and robust financial position. With a 58.53% increase in operating income YoY, totaling around $60.22 million, the company has achieved a net profit of approximately $2.44 million. BLT has successfully expanded its presence in the aerospace and aviation sector, collaborating with major global aerospace players. Additionally, the company has ventured into the consumer market and is making strides in electronics. BLT continues to focus on mass production capabilities and is expanding its production capacity to meet increasing demand.

Software news from Markforged Holding Corporation, SelectAM, and Artec 3D

3D printer manufacturer Markforged has unveiled Digital Source, an on-demand platform enhancing part management by enabling the licensed 3D printing of certified parts as needed. Manufacturers can upload digital part designs, securely licensing them to clients, distributors, and manufacturers. Users can then print these parts onsite or via authorized service providers. BMF, an early adopter, replaced up to 60 components every three to four months in their sandblasting machines. Digital Source lowers inventory costs, streamlines replacements, and promotes sustainability. Project DIAMOnD, the world’s largest emergency response network for 3D printing, plans to implement Digital Source to further AM adoption.

Finnish AM software company SelectAM has introduced an end-to-end workflow from AM part identification to delivery. The AI-powered platform, available as a free open-access version, enables users to assess CADs and part-related data, receive instant AM price quotes, estimate savings compared to conventional manufacturing, and more. Users can access premium features with a subscription, allowing them to simulate processes, calculate production costs, and find the best AM technology for their parts. The platform streamlines part identification and qualification for AM, saving time and simplifying the ordering process for various AM technologies and materials.

Luxembourg-based 3D scanner manufacturer Artec 3D has unveiled Artec Studio 18 (AS18), enhancing the capabilities of its 3D scanners and data processing software. AS18 features unique capabilities, including the seamless merging of multi-resolution datasets from various Artec 3D scanners and rapid data processing. The software also incorporates AI to create lifelike color 3D models. AS18 streamlines reverse engineering and quality inspection tasks, offering instant defect identification and compliance with industry tolerances. The software is certified by the German standards authority PtB for its 3D metrology capabilities. With its enhanced features and AI-powered texture enhancement, AS18 aims to unlock opportunities across various industries.

“Artec Studio 18 unlocks new possibilities, allowing users to combine data from entirely different scanners at the click of a button,” said Art Yukhin, President and CEO of Artec 3D. “With the handheld Artec Leo and long-range Artec Ray II, it’s now possible to create incredibly detailed digital twins of huge areas like factory floors. This innovation, along with advances in the AI we use to improve scan speed and quality, shows how we continue to be pioneers in the 3D field.”

Renishaw’s Sir David McMurtry awarded I-Form Advanced Manufacturing Excellence Award 2023

Sir David McMurtry, the Co-Founder and Executive Chairman of Renishaw, a global engineering technologies firm, has been honored with the I-Form Advanced Manufacturing Excellence Award 2023. This accolade, bestowed at the 72nd CIRP General Assembly held at University College Dublin, acknowledges McMurtry’s notable contributions to advanced manufacturing innovation and research spanning decades. With 2023 marking the 50th anniversary of Renishaw’s founding, this award underlines McMurtry’s dedication to engineering fields, including dimensional metrology and metal additive manufacturing (AM). The I-Form Advanced Manufacturing Research Centre, featuring Renishaw’s RenAM 500 series metal AM system, highlights the company’s commitment to collaborative research in advanced manufacturing.

“We pride ourselves on contributing to the global advanced manufacturing research and innovation industry”, said Will Lee, Chief Executive at Renishaw. “This is a great honour for Sir David and Renishaw, and our aim is to be able to continue making a positive impact on production engineering around the world, helping our customers to make advancements in their ability to manufacture their products accurately and efficiently.”

Law and regulatory news from Sigma Additive Solutions, and Nano Dimension

Sigma Additive Solutions is set to conduct a 1-for-20 reverse stock split of its outstanding common stock to meet the Nasdaq Listing Rule 5550(a)(2) requirement of a minimum $1.00 bid price per share before the October 8, 2023 deadline. This move is expected to facilitate the acquisition of NextTrip Holdings, Inc. and the sale of certain quality assurance software assets, as indicated in non-binding letters of intent. Following the split, the company’s common stock will continue trading on the Nasdaq Capital Market under the symbol “SASI” with a new CUSIP number. The reverse stock split will not change stockholders’ percentage ownership but will reduce outstanding shares from approximately 12,227,135 to about 611,357 shares, plus any fractional shares exchanged for whole shares. All other financial instruments tied to the stock will be adjusted accordingly.

Israeli electronics 3D printer manufacturer Nano Dimension has filed a patent application for utilizing large language models (LLM) in analyzing data produced by industrial machines. This application, named “Large Language Models for the Log File Analysis of Industrial Machines,” is aimed at enabling real-time data analysis and scalable implementation in Nano Dimension’s systems and solutions for external customers. The patent focuses on analyzing “log data alpha-numeric streams,” which pertain to industrial process operation and parameters, often involving numerous parallel subsystems. This technology, developed by Nano Dimension’s in-house AI group DeepCube, brings ChatGPT-like capabilities to analyzing extensive log streams with real-time, cost-effective scalability.

Catalysis expands into Europe with 3D printed tooling license

US-based 3D printed tooling solutions provider Catalysis Additive Tooling, has granted a license for its novel 3D printed tooling technology to innoMold, a respected company near Düsseldorf, Germany. Operating as “Catalysis Additive Tooling GmbH,” innoMold will leverage this advanced technology to manufacture tools, beginning operations in October 2023. This technology, utilized in thermoforming, seat foam manufacturing, and jigs and fixtures, enables global customers to significantly reduce tooling costs and manufacturing time, resulting in faster product launches and reduced cost per unit.

Darrell Stafford, President/CEO of Catalysis Additive Tooling, expressed his enthusiasm, said, “I’m thrilled to announce the licensing of our 3D printed tooling technology in Europe. The remarkable company culture and determination exhibited by innoMold make them an ideal partner for Catalysis as we aim to strengthen our global leadership position in 3D tooling applications.”

A walk down UpNano’s 5-year journey

Vienna-based two-photon polymerization (2PP) specialist UpNano is marking its fifth anniversary as a pioneer in high-resolution 2PP 3D printing. Founded in 2018, UpNano has made significant strides in the global 3D printer market, introducing innovations like the tilt-frame mechanism, advanced bio inks, and software upgrades to enhance printing speeds. The NanoOne 3D printer lineup has garnered exponential sales growth, attracting attention from academia and industry alike, with MIT.nano partnering with UpNano to showcase the technology in the United States. With a focus on precision and speed, UpNano continues to advance 2PP 3D printing, making it a contender in serial production applications.

Bernhard Küenburg, CEO of UpNano, said, “When UpNano was founded in 2018, the landscape of high-resolution 3D-printers was disappointingly sparse. This scarcity spurred us to overcome the limitations of existing systems. Just a year later, we introduced a significantly more potent laser system coupled with a patented adaptive resolution technology. The result was the NanoOne printer series, capable of high-resolution 3D-printing across an astounding twelve orders of magnitude.”

3D printing applications from Balena, and GREENFILL3D

Material science company Balena has partnered with designer Kitty Shukman to create the “ROOTS” 3D printed slide. Utilizing Balena’s BioCir, a fully compostable elastomer, Shukman’s design integrates roots and stems into the slide’s structure. This collaboration exemplifies the fusion of fashion, technology, and environmental responsibility, paving the way for eco-conscious design. The distinct left and right shoes symbolize organic growth. Balena seeks to revolutionize fashion’s sustainability with 3D printing and advanced materials like BioCir. This venture highlights the circular potential of BioCir in 3D printing and its scalable manufacturing process, offering responsible end-of-life recycling in industrial compost facilities, and supporting a sustainable future.

“I continually strive to strike a balance between functionality, sustainability, and style, and working with the Balena team to envision this new design has helped me imagine a day when our fashion industry becomes truly circular,” said designer Kitty Shukman. “I hope to see 3D printing continue to leave its mark as a unique, bold, and sustainable medium in the fashion industry on its way to becoming climate neutral.”

Who will win the 2023 3D Printing Industry Awards? Make your nominations now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed slide. Photo via Balena.