In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new materials, partnerships, and business deals, and HP collaborating with GLAMOUR to develop 3D printed awards.

Read on for the most recent updates from MxD, Meltio, Axial3D, Nikon, Revo Foods, AddUp, and more.

Don’t forget to cast your votes for the 2023 3D Printing Industry Awards!

Emerging partnerships news from MxD, Meltio, Evolve Additive Solutions, and more

Starting off with partnerships, UK-based medical technology firm Axial3D and GE HealthCare have partnered to bridge the gap between MRI images and 3D patient-specific outputs in medical imaging. The collaboration aims to offer healthcare professionals enhanced insight into patient anatomy, enabling precise diagnoses and treatment planning. By combining GE HealthCare’s MRI-based bone imaging application with Axial3D’s FDA-cleared imaging segmentation platform, the goal is to create radiation-free 3D visualizations and printing of patient-specific anatomical models. This can reduce the need for upfront 3D printing investments, improve surgical planning, potentially reduce time in the operating room, and emphasize the role of MRI in pre-surgical imaging.

MxD, the digital manufacturing and cybersecurity institute, has partnered with the National Institute of Standards and Technology‘s (NIST) Hollings Manufacturing Extension Partnership (MEP) in a five-year collaboration aimed at promoting digital adoption among small and medium-sized manufacturers (SMMs). This partnership will offer tailored support to enhance digital adoption, with a focus on cybersecurity readiness and funding opportunities. MxD provides digital manufacturing resources and emphasizes workforce development. NIST MEP, with its nationwide network, has a proven track record of assisting SMMs, resulting in substantial economic growth and job creation. The collaboration will ensure alignment and responsiveness to evolving market needs.

Next up, Precise Trading LLC, based in Dubai and Riyadh, is now an official sales partner for Meltio, a Spanish Additive Manufacturing company. It will promote and distribute Meltio’s solutions in the Gulf Cooperation Council (GCC) region, collaborating with various organizations, including technology centers, tooling machine companies, and academia.

Francisco González, Sales Manager for EMEA at Meltio, stated, “We are thrilled to be working with companies like Precise as their expertise as well as customer-centric approach are exactly what we are looking for when incorporating partners in the Meltio partner ecosystem. Together, we will be able to cater to the ever-growing needs of the GCC market for, and ease the adoption of metal Additive Manufacturing.”

AM-Austria with over 70 members is inviting organizations to join in shaping the future of additive manufacturing, offering support, international exposure, and opportunities for collaboration. The platform aims to promote innovation, create ideal conditions, and influence AM’s development in Austria. Austria has emerged as a notable European innovation hub for additive manufacturing (AM). AM-Austria, a key platform, connects the Austrian AM sector’s various stakeholders, fostering interdisciplinary collaboration. Austria has seen remarkable growth in AM, with a 1300% increase in patent applications between 2014 and 2017, ranking fourth globally in AM device manufacturing and first in per capita.

Evolve Additive Solutions has partnered with alphacam to provide Selective Thermoplastic Electrophotographic Process (STEP)-manufactured parts as a service in Europe. STEP is an additive manufacturing technology that addresses limitations in accuracy, scalability, and material capabilities found in other methods. alphacam, known for its expertise in plastic part printing, will use Evolve’s Scaled Volume Production (SVP) platform to produce high-quality thermoplastic parts. This partnership extends Evolve’s mission to establish STEP production centers globally, making this technology accessible for end-use parts and reducing reliance on traditional manufacturing methods.

“We have experienced increasing demand for STEP parts in Europe, especially in automotive, consumer electronics, medical device and retail markets, as well as with fluid and airflow applications,” said Jeff Hanson, Evolve’s Senior Vice President of Go-to-Market. “Given their rich history and leadership in additive manufacturing, alphacam is the ideal partner to bring STEP technology to European industrial sectors.”

Additionally, Hamburg-based AM consultancy AMPOWER has partnered with Nikon to provide comprehensive training in additive manufacturing solutions. The collaboration will offer engineers an in-depth understanding of Nikon’s AM technology, starting with an online learning program focused on the Lasermeister 100A Series. This initiative will cater to potential customers and professionals looking to explore the potential of Nikon’s Lasermeister technology. Nikon aims to leverage AMPOWER’s expertise to nurture engineering proficiency in their AM solutions, enhancing skills and driving the adoption of AM technology across industries. Further E-Learning modules are planned for 2024, fostering innovation and engineering capabilities.

“At AMPOWER, we see a transformative power in AM, and we are excited to work with Nikon to enable engineers to fully harness the capabilities of their AM solutions,” said Matthias Schmidt-Lehr, Managing Partner of AMPOWER. “The newly designed training program which has been developed by AMPOWER, will provide engineers with the necessary knowledge, skills, and insights they need to leverage Nikon’s AM technologies effectively.” Adds Hiroyuki Nagasaka, Department Manager of the Development Department in the Advanced Manufacturing Business Unit of Nikon.

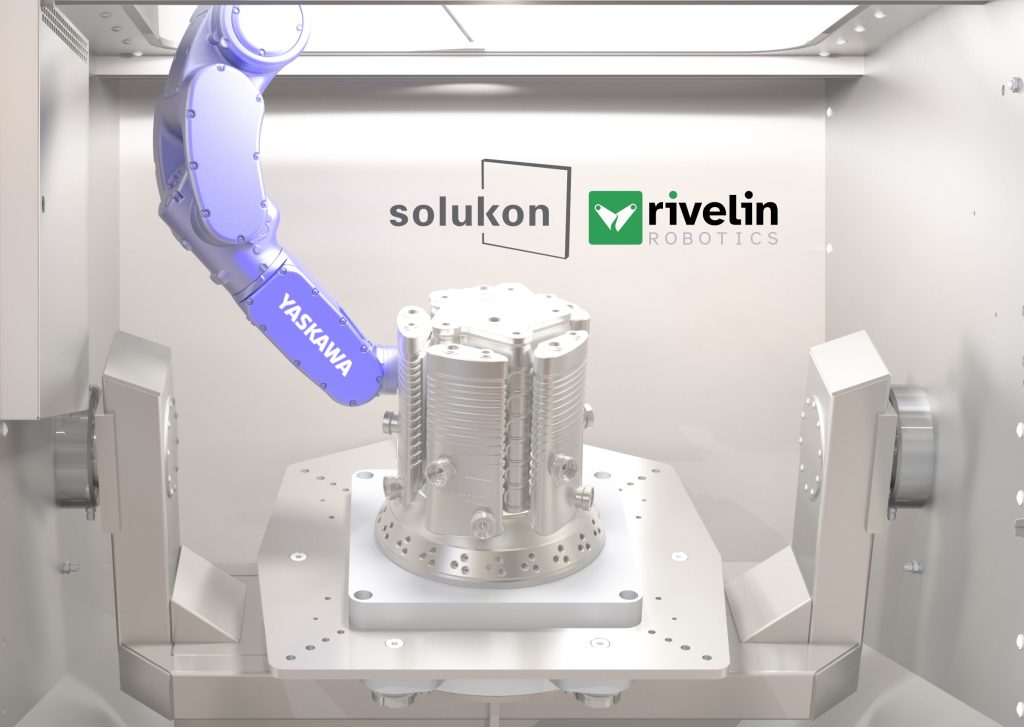

Rivelin Robotics and Solukon are collaborating to develop advanced automated solutions for post-processing metal and metal additive manufacturing (AM) applications. Their joint efforts aim to address the demands of many metal AM users, specifically focusing on areas like automated powder removal and precise robotic support removal and finishing. They intend to provide a system that can include robotic compressed air blasting, localized vibration for depowdering, robotic sensing solutions for channel inspection, and various media blasting for surface enhancement. The complete system is set to debut at Formnext 2023 in Frankfurt, with both companies presenting their contributions.

3D printing applications by Revo Foods, AddUp, and more

Diving into applications, food-tech startup Revo Foods has expanded its 3D printed vegan salmon filet, “THE FILET – Inspired by Salmon,” to most European countries starting on October 1st. This product addresses the growing demand for sustainable seafood alternatives and aims to provide an authentic salmon experience for flexitarian consumers. It is created using Revo Foods’ patented MassFormer technology, offering a juicy, traditional fish-like texture. The main ingredient, mycoprotein, is produced with minimal resource requirements and has an excellent Nutriscore rating. It’s a novel 3D printed product and part of the growing trend toward sustainable and safe alternatives to conventional seafood, aligning with concerns about fish safety and environmental impact.

3D printer OEM AddUp has showcased its expertise in 3D printing by creating intricate metal sculptures for the “Beautés Exposition.” These sculptures, named Les Armeuses, are highly detailed neck collars inspired by 19th-century fashion. They were crafted by artist Agnès Geoffray during her residency with AddUp at the FRAC Auvergne. Each piece, designed in collaboration with AddUp’s team, will be produced in limited editions. This artistic endeavor demonstrates the company’s precision and innovation in 3D printing technology, says the company.

GLAMOUR, an imprint of Condé Nast, has hosted its 17th Women of the Year Awards at One Marylebone in London, with sponsorship from Samsung. The event recognized feminist heroes. To craft the awards for this occasion, GLAMOUR partnered with HP’s Personalization & 3D Printing division. These awards were produced using HP’s multi jet fusion (MJF) technology and eco-friendly PA 11 material, sourced from castor beans. Among the distinguished awardees were America Ferrera, celebrated for her role in Ugly Betty, Ariana DeBose from West Side Story and Hamilton, musician Olivia Dean, and celebrity Emily Ratajkowski.

Staying with trophies, 3D Printing Industry is currently running a design competition with Thangs to find a winning design for this year’s 3DPI awards. More information about the competition and prizes here.

At the Formnext 2023, Lithoz will unveil its latest multi-material 3D printing technologies, showcasing various multi-functional parts. These parts are created using the CeraFab Multi 2M30, making its appearance at the trade show. The 3D printer can combine different materials within a single functional part, revolutionizing multi-material 3D printing in the ceramic industry. Visitors can explore these parts for a ‘touch and feel’ experience. The success of Lithoz’s partners and technology in industrial-scale ceramic 3D printing will also be highlighted. Additionally, Lithoz will also present novel applications in healthcare applications, dental restorations, and bioresorbable ceramics, elevating surgical precision and patient well-being.

Construction news from Tvasta, and Mighty Buildings

Followed by construction updates, Kerala’s first 3D printed building, called AMAZE-28, was inaugurated on October 10 at the Kerala State Nirmithi Kendra (Kesnik) campus in Thiruvananthapuram (Trivandrum). Created as a demonstration project, this one-room, 380 sq ft summer house was swiftly built in 28 days by Tvasta, a Chennai-based construction tech start-up. Tvasta used a patented concrete mix, and 3D printing technology to construct the building layer by layer, guided by a digital model. The approach offers time efficiency, minimal waste, and greater creative potential. Kesnik and Tvasta have more 3D printing projects planned, garnering interest from institutions like the Vikram Sarabhai Space Centre (VSSC) and the Kerala Infrastructure Investment Fund Board (KIIFB). The demo project’s cost was ₹11 lakh, and it has the potential to expedite the construction of larger homes within two to two-and-a-half months.

R. Buckminster Fuller Dome Home Not-For-Profit and Mighty Buildings have announced a joint project to design and develop a new visitor center and museum at the site of the iconic “Bucky Dome” home in Carbondale, IL. The Bucky Dome, a National Historic Place, served as the visionary architect R. Buckminster Fuller’s home from 1960 to 1971. The project aims to connect Fuller’s legacy with future sustainable building innovations, utilizing Mighty Buildings’ 3D printing construction methods and new materials. The 2,400-square-foot museum, designed by architect Thad Heckman, will explore Fuller’s legacy and the future of architecture. The use of 3D printing technology highlights the potential for reduced construction timelines and minimal waste.

Scott Gebicke, CEO of Mighty Buildings, said, “We are proud to partner with the R. Buckminster Fuller Dome Not-for-Profit in creating a sustainable future in harmony with Fuller’s masterful vision. The design of our parametric panels pays tribute to his groundbreaking work while showcasing the capabilities of 3D printing in construction. Together, we are advancing the cause of sustainable architecture combined with advanced construction technology.”

VDL ETG acquires metal 3D printer from Additive Industries

Mechatronic systems provider VDL ETG has acquired the MetalFABG2 3D metal printer from Additive Industries. This strategic move reflects VDL ETG’s commitment to innovation, precision, and efficiency. The MetalFABG2’s ability to create intricate shapes, primarily from stainless steel, enhances production versatility, reduces production time, and minimizes material waste. VDL ETG has swiftly embraced MetalFABG2’s capabilities, promising accelerated development and assembly of its products. This acquisition marks a significant step forward in the company’s technological capabilities.

Mark Massey, Chief Executive Officer at Additive Industries, said, “Partnering with VDL ETG and seeing them swiftly integrate the MetalFABG2 into their processes has been an affirmation of our shared vision for innovative manufacturing. We are excited about the transformative impact this will have in the mechatronics domain.”

CRP Technology introduces Windform TPU

CRP Technology has launched Windform TPU, a highly elastic thermoplastic polyurethane, that offers versatility in various sectors, including transport, robotics, design, and sports equipment. It is suitable for manufacturing automotive components, gimbal bellows, air cleaner covers, hoses, grips, connectors, joints, snap fits, sports protection gear, and running shoe outsoles due to its excellent abrasion resistance. Windform TPU can also be used for low-temperature applications and in contact with oils, greases, and solvents. This expands the Windform TOP-LINE 3D printing materials to eleven in total.

Wikifactory streamlines collaboration with Wikifactory for Teams

Wikifactory has introduced ‘Wikifactory for Teams,’ a private beta program tailored for industrial designers and engineering teams. This initiative enables teams to collaborate on optimizing their workflows for accelerated product development. Participants can offer feedback, collaborate on innovative solutions, and access support from Wikifactory’s product team. The inaugural release, ‘Wikifactory Desktop’ App, simplifies real-time collaboration with features like file synchronization and efficient design review. Wikifactory streamlines decision-making, provides an advanced 3D CAD viewer, and integrates task management, permissions, and annotations. It also offers online manufacturing services, emphasizes security, and provides tailored pricing options, including educational initiatives. Over 140,000 product developers and engineers across diverse industries use Wikifactory for collaborative product development.

JOEL introduces a new electron beam-powder bed fusion system

JEOL has introduced its JAM-5200EBM Electron Beam-Powder Bed Fusion system to Cumberland Additive at Pittsburgh International Airport’s Neighborhood 91. The system was operational within six days of arrival and produced an AMS 7032 compliant build within three weeks. It previously completed operational qualification per AMS 7032 specifications in Japan. The system will initially focus on Titanium alloy and can be adapted for Pure Copper and Nickel 718 alloy production. JEOL will host a webinar on November 1st to share insights on the system’s capabilities and results. The company will also participate in Formnext 2023.

Photopolymer Week event brings together industrial experts

Last month, the first Photopolymer Week event took place in Boulder, Colorado, bringing together experts from research labs, universities, and industry. The event featured a workshop presented by the Photopolymer Additive Manufacturing Alliance (PAMA), in alliance with the National Institutes of Standards and Technology (NIST), focusing on advancing photopolymer technology and its applications. The PAMA Workshop discussed various topics, including AI-driven materials, biomedical applications, sustainability, new use cases, and public-private partnerships. Following the workshop, the Photopolymerization Fundamentals conference addressed the latest research and developments in photopolymerization, with a strong focus on materials, 3D printing, and medical applications.

Voting has now started for the 3D Printing Industry Awards 2023. Cast your vote now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Kerala’s first 3D printed building. Photo via The Hindu.