In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new materials, partnerships, and business deals, and 3D printed terracotta cooler gives a modern yet traditional makeover to air-conditioning.

Read on for the most recent updates from Element Materials, Farsoon, Mechnano, Enable 3D, Renishaw, and more.

Materials news from Element Materials, and Farsoon

Starting off this week with materials update, global certification and testing company Element Materials has achieved a significant milestone by gaining approval from GKN Aerospace for its Antwerp laboratory. This recognition highlights Element’s investment in powder characterization expertise, solidifying its role in the industry and expanding its capabilities in additive manufacturing. Element’s commitment is evident through its Antwerp and Teesside labs, offering ISO/ASTM 52907-compliant metallic testing services. These labs, staffed by experienced experts and equipped with advanced technology, focus on essential aspects like composition, particle size, and contamination. This ensures the quality of 3D printed materials and adherence to specifications. As industrial use of additive manufacturing grows, Element’s labs assist in the transition to active production from research and development.

Industrial polymer and metal laser sintering systems provider Farsoon has endorsed Mechnano‘s PK ESD for use with its 252P Series and Flight 403P Series machines. PK ESD combines Jabil‘s engineered powder and Mechnano’s D’Func carbon nanotube coating, adding uniform electrostatic dissipative properties to laser-sintered parts. Retaining PK 5000’s eco-friendly, impact-resistant, and chemically resistant traits, PK ESD is suitable for functional testing and production. Enabled by D’Func, PK ESD parts achieve Nano-Uniform ESD at 107 ohms while maintaining mechanical performance and enhancing impact resistance and elongation. This advancement simplifies AM applications and opens new possibilities for end-use scenarios.

Partnership news from Desktop Health, Renishaw, Solukon, Enable 3D

Moving on to partnerships, Desktop Metal subsidiary Desktop Health, and Carbon have validated Flexcera Smile Ultra+ for Carbon’s platform, expanding access to the nanoceramic resin for dental labs globally. This collaboration marks the first time Desktop Health’s proprietary resin is available to another 3D hardware provider. Flexcera Smile Ultra+ redefines digital dentistry with strong, lifelike restorations like dentures, crowns, and veneers. The material leverages proprietary long-chain chemistry for optimal dental prosthetics. Desktop Metal’s CEO, Ric Fulop, expressed enthusiasm for the partnership, while Carbon’s CEO, Phil DeSimone, highlighted the industry’s shift towards digital dentures. Flexcera Smile Ultra+ is FDA 510(k) Class II cleared and available in the US, with EU availability forthcoming.

UK-based engineering firm Renishaw, in alliance with British Cycling and other partners, unveils the Hope-Lotus track bike, a cutting-edge creation set to be ridden by Great Britain’s track cyclists at the 2023 UCI Cycling World Championships in Glasgow and the 2024 Paris Olympic Games. The collaboration with Lotus Engineering and Hope Technology involved bespoke components like aerodynamic forks and handlebars. Renishaw’s additive manufacturing expertise rapidly produced plastic and metal prototypes for aerodynamic testing, with parts refined for strength and geometry. This alliance showcases how technology enhances bike performance, offering optimized design for individual athletes. The lightweight, advanced bike aims to secure valuable marginal gains in competitions, enhancing British athletes’ performance.

Reichenbacher and Solukon have collaborated to enhance the postprocessing of 3D printed metal parts by automating both unpacking and depowdering. This joint effort integrates the removal of unfused powder from complex structures. The process begins by loading the entire container with the part into the SFM-AT1000-S. The container is rotated and emptied of loose powder, which is then prepared externally. Following this, Solukon’s system employs SPR technology for cleaning using precise movements calculated from the part’s CAD file. The solution handles containers weighing up to 800 kg and employs high-frequency vibration to tackle challenging powder clumps within the part’s internal channels.

Hungarian designer Adam Miklosi has collaborated with Enable 3D for Uppgradera Collection 3, a series of IKEA hacks created through 3D printing. Miklosi draws inspiration from IKEA products to enhance designs and address issues. The collection offers free downloadable designs for home-based 3D printing, emphasizing consumer participation in creation. Enable 3D’s approach disrupts traditional value chains, promoting co-production and a circular economy with fully reusable mono-materials. The collaboration aims to amplify user experience and revolutionize consumption through innovative, consumer-driven designs.

Business deals and acquisitions from Cadpro, AML3D, and Phase3D

Diving into business deals and acquisitions, Cadpro has acquired Australian Cross Technology Group for enhancing CAD technology and services in the Australian design and engineering sectors. With expertise in Autodesk product consulting and training, Cross Technology enriches Cadpro’s offerings for an improved customer experience. Hans Grootegoed, MD of Cadpro, welcomes the addition, aiming to amplify capabilities across ANZ, driving digital transformation in architecture, engineering, construction, design, and manufacturing. Clients retain access to software and support, while new team members and broader expertise create exciting possibilities. Doing so, amplifies customer excellence and knowledge-sharing, strengthening both entities in the market.

Australian large-format 3D printer manufacturer AML3D has sold its ARCEMY ‘X-Edition 6700‘ Wire Arc Additive Manufacturing (WAAM) metal 3D printing system to the U.S. Navy’s Additive Manufacturing Center of Excellence (AM CoE) in Danville, Virginia. The AUD$1.1 million (US$771,686) order, facilitated by AML3D’s value-added reseller Philips Corporation, aims to enhance the U.S. Navy’s supply chain and industrial base resilience. The ARCEMY X system is set for installation by early 2024, reinforcing the Navy’s commitment to adopting advanced additive manufacturing technologies for innovative and competitive growth in defense and submarine sectors. This second ARCEMY X order showcases the Navy’s trust in AML3D’s capabilities.

Additionally, AML3D has secured a European patent for its WAM process, aligning with its Australian patent. This patent from the European Patent Office covers AML3D’s approach to crafting 3D metal parts, enhancing its intellectual property protection and reinforcing its standing in advanced metal 3D printing. Notably, AML3D stands as the sole additive manufacturing entity with a European process patent, solidifying its position as a Wire Additive Manufacturing technology leader on the continent, says the company. While concentrating on expanding ARCEMY system sales to U.S. Defense, Marine, and Aerospace sectors, AML3D intends to extend its influence to European industries, offering time and cost-efficient customized components to bolster supply chains.

“This is a significant milestone for our company and our technology journey. The granting of this patent is further validation of our proprietary technology and also secures our position as a global provider of a major industrial metal 3D Printing process. The market demand for advanced wire feedstock additive manufacturing, that can address supply chain risk, deliver time and cost savings and better ESG outcomes continues to accelerate. This additional international process patent protection will further strengthen our position in a significant and growing addressable market,” said AML3D Interim CEO Sean Ebert.

Chicago startup Phase3D has secured a $1.25 million, two-year contract from the Air Force Research Lab (AFRL) to develop an inspection system for cold spray additive manufacturing (CSAM). This technology, slated for installation at South Dakota’s Ellsworth Air Force Base, holds promise for efficient defense-related part production and repair. Presently, gathering objective data during CSAM poses challenges. Phase3D’s flagship Fringe in-situ inspection system will be adapted to ensure uniform material deposition, fostering broader CSAM adoption by providing repeatable, quantifiable data. Collaborating with VRC Metals, Phase3D aims to validate structured light measurements, offering real-time quality monitoring for CSAM’s applications.

3D printing applications updates from Mechnano, and Entreautre

Amid rising global temperatures, air conditioning has shifted from luxury to vital need, but environmental concerns persist. In response, designer Simon Pavy and global agency Entreautre teamed up for an eco-friendly solution: the low-tech terracotta cooler. This concept draws inspiration from ancient cooling practices seen in the Middle East, India, and Egypt. A 3D printed, porous terracotta vessel forms the core, utilizing nature’s evaporative cooling principles. Leveraging Grasshopper software and ceramic 3D printing, designers enhance functionality and aesthetics. The cooler’s potential to revolutionize cooling methods for sustainability and comfort highlights the harmonious blend of tradition and innovation. The low-tech terracotta cooler signifies hope for a greener, cooler world amid climate change challenges.

Arizona-based 3D printing company Mechnano introduces D’FuncTM, its trademarked proprietary process that enhances electrical and mechanical performance in groundbreaking additive manufacturing masterbatches and materials. With over 130 patents, D’Func addresses challenges caused by “dirty tubes” (clumped CNTs), improving AM material properties. It offers Nano-Uniform ESD protection, countering insulative pockets, lightning rod effects, and residual metals in ESD applications. The term “D’Func” originates from Mechnano’s R&D lab, reflecting its “commitment to innovative solutions.” D’Func assures consistency and reliability in Nano-Uniform ESD properties, emphasizing its importance in protecting sensitive electronics within AM materials.

Certifications news from Makers Empire, Axial3D, and MakerVerse

Australian EdTech company Makers Empire, achieved B Corporation (B Corp) certification, validating its commitment to positive impact. Known for creating leading EdTech products for schools, using 3D technology to engage students in STEM and design thinking, Makers Empire now joins over 560 B Corp businesses in Australia and NZ, and 7,000+ globally. B Lab’s rigorous assessment process evaluates social and environmental performance. This certification underscores adherence to high standards for impact, governance, accountability, and transparency. Makers Empire’s user-friendly 3D design software, used by 2.8+ million students across 50+ countries, enhances spatial reasoning, reduces STEM anxiety, and fosters creativity. It’s backed by research and partnerships for widespread STEM learning.

Medical segmentation and 3D solutions provider Axial3D has secured FDA clearance for an automated, AI-driven cloud-based platform for orthopedic trauma, maxillofacial, cardiovascular, and orthopedic applications. This marks Axial3D’s second FDA clearance for its INSIGHT segmentation platform, a breakthrough in healthcare’s adoption of AI and automation for personalized patient care. With its AWS cloud infrastructure and AI algorithms, INSIGHT converts 2D DICOM images into accurate 3D visualizations, mesh files, or 3D printed anatomical models. By streamlining image segmentation, Axial3D empowers healthcare providers and medical device firms, improving diagnostic accuracy, treatment planning, and surgical interventions, while enhancing patient-specific programs and accelerating the design of personalized devices.

Industrial parts sourcing platform MakerVerse has achieved ISO 27001:2017 certification for information security. This globally recognized standard validates its robust information security management system (ISMS) covering controls, data protection, and continual improvement. TÜV SÜD‘s rigorous audit assessed MakerVerse’s ISMS, including secure development practices, access controls, and cryptography. This achievement highlights MakerVerse’s commitment to top-tier data security and customer service, adding to its ISO 9001 certification for quality management.

Distribution deals updates from Meltio and AddUp

Metal 3D printer developer Meltio has officially appointed IRTI Robotics as its sales partner. The partnership will see IRTI Robotics take on a crucial role in integrating and supporting Meltio’s Engine Robot solution within the Indian market, particularly for Metal Additive Manufacturing. Meltio’s unique metal 3D printing approach employs welding wire as a feedstock. IRTI Robotics’ focus will be on seamless integration and business development, collaborating with academia, tooling machine companies, and industry players to enhance Meltio’s presence and offerings in India.

Industrial metal 3D printer manufacturer AddUp has integrated Constellium’s Aheadd CP1 aluminum alloy into its FormUp 350 machines, broadening its material selection for additive manufacturing. Aheadd CP1, developed for laser powder-bed fusion (L-PBF), offers improved productivity and heat dissipation compared to conventional aluminum alloys like AS7 and AS10. This alloy streamlines post-build processes, requiring a simple 400°C heat treatment. With mechanical properties akin to AS7 and enhanced thermal conductivity, Aheadd CP1 holds promise for aerospace applications, potentially expanding its utility beyond motorsports. The material’s success in motorsports hints at wider industrial applications, supported by the performance of AddUp’s FormUp 350 system.

Pennsylvania State University brings news for the medical sector

Pennsylvania State University (PSU) researchers spearheaded a project to develop advanced bioprinting technology capable of efficiently producing human tissues at a large scale. With a $2 million grant from the National Institute of Biomedical Imaging and Engineering at the National Institutes of Health, the team, led by Professor Ibrahim T. Ozbolat, aims to create the first-ever system for fabricating native tissues, including bones, tracheas, and organs. Building on previous work with cellular aggregates, the technology, named “high-throughput spheroid bioprinting,” will enable simultaneous printing of multiple cell clusters, boasting high accuracy and unprecedented speed. This interdisciplinary effort combines expertise in bioprinting, biomaterials, and tissue engineering.

“This technology, once fully developed, can be applied for the fabrication of a variety of human tissues,” said co-principal investigator Elias Rizk, a professor of neurosurgery at Penn State College of Medicine. “It could be cardiac tissue or lung tissue. It could be skin or even bone, which is tissue. This technology could repair bone in a rapid manner, even in sensitive places like the skull.”

PUNCH Torino uses Markforged’s simulation tool to improve 3D printing process

European R&D and engineering hub PUNCH Torino has enhanced its 3D printing process using Markforged‘s Simulation tool. The challenge was producing accurate prototype engines with precisely timed components. The team designed specialized camshaft locking tools made from reinforced Onyx with fiber to prevent camshaft movement during tightening, ensuring synchronization. Previously, this demanded numerous tool iterations and substantial time investment. With Markforged’s Simulation, PUNCH Torino has reduced the average iterations from eight to three, saving about 18 hours per jig, streamlining engineering modifications, and optimizing fiber arrangement. This tool shows potential for refining part design and improving deliveries for PUNCH Torino’s clientele.

AM automates design and production, mitigating manual labor needs

UK’s offshore energy industry, Offshore Energies UK (OEUK) published a report in December 2022 emphasizing a skills shortage across the industry. Additive manufacturing, however, offers a solution to the dearth of expertise by automating design and production, mitigating manual labor needs. Dave Moore, 3D print consultant at Tri-Tech 3D, a UK provider of Stratasys, One-Click Metal, and XJet 3D printing solutions, explains how AM can deskill oil and gas part production. With advanced materials and systems, AM extends to the production line, facilitating applications like investment casting, sand casting, and composite layup tools, alongside optimizing turbo machinery, rotors, and other components. This shift toward AM presents a promising path to address skills shortages in the offshore energy sector.

Bond3D introduces a novel solution to material shrinkage in 3D printing

Dutch 3D printing company Bond3D, collaborating with AniForm, has introduced a unique solution to a common 3D printing challenge – material shrinkage during cooling. Conventional materials like PEEK contract by 3.5% upon cooling, often leading to print inaccuracies. Bond3D’s innovation involves a custom software solution that calculates and compensates for local shrinkage and warping during the printing process. By adjusting the toolpaths in three dimensions – X, Y, and Z – the technology ensures that the final cooled product accurately aligns with the intended design. This advancement not only reduces the need for post-processing but also streamlines design iterations, curtails material waste, and notably shortens lead times.

Volkmann USA unveils vDryer, a Vacuum Dryer for metal powders

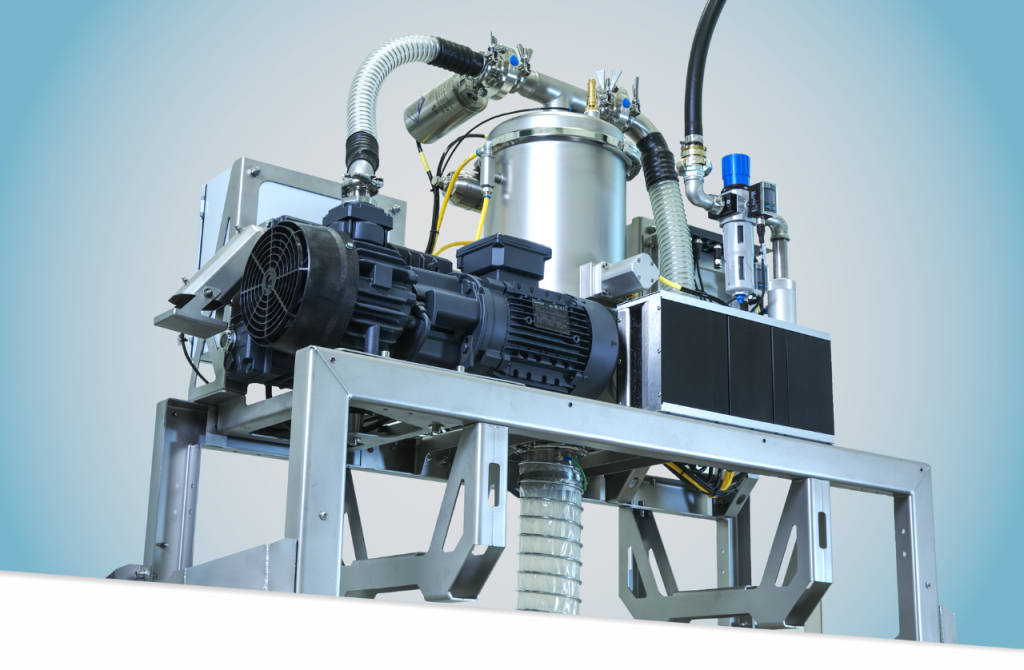

US-based 3D printing equipment manufacturer Volkmann USA has unveiled the vDryer vacuum dryer. Designed to enhance metal part production quality, the vDryer restores metal powders to the necessary moisture content level for build jobs. Using electric vacuum pump technology, it swiftly removes moisture without applying heat. Tested by BMW Group for better 3D-printed metal parts, the system can be placed upstream or downstream from printers, improving powder quality. It’s complemented by Volkmann’s pneumatic vacuum conveyors to seamlessly transfer dried powder for storage or printing.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed bike on the track. Image via Renishaw.