In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, acquisitions, and partnerships in the 3D printing sector.

Today’s edition includes a spate of new 3D printing partnerships, awards and certifications, software upgrades, 3D printing developments within space, automotive and medical, and some rather funky Egyptian Lotus flower-inspired 3D printed lamps.

Read on for the most recent updates from Additive Industries, Wagner Machine Company, ADDMAN Engineering, Wall Colmonoy, NUBURU, Shree Rapid Technologies, Gardner Business Media, FIT AG, pro-beam, Cincinnati Incorporated, Khawarizm Design Studio, LIBERTY Power Metals, and more.

New 3D printing partnerships from ExOne, VELO3D, Ohio State University, FIT AG, and Shree Rapid Technologies

Kicking off this week’s news, binder jet 3D printer manufacturer ExOne has announced the addition of four new sales channel partners to expand its distribution footprint throughout the US and Canada. Computer Aided Technology (CATI), TriMech Solutions, Javelin Technologies, and Purple Platypus will sell ExOne’s Innovent+ metal binder jetting systems alongside the Metal Designlab from Rapida, ancillary equipment, and consumables.

Alongside previous experience in selling metal 3D printing systems, the four companies also sell technology from the likes of 3D printer manufacturer Stratasys and SOLIDWORKS.

“We are delighted to welcome such knowledgeable and accomplished partners to the ExOne team,” said John Hartner, ExOne CEO. “As manufacturers in the US and Canada look to shorten supply chains and localize production of more products, our entry-level metal printing systems are a great way to get started with bound metal 3D printing technologies that deliver high-quality parts at an affordable price.”

Elsewhere, 3D printer manufacturer VELO3D has been busy securing 3D printing distribution partnerships with both precision machine shop Wagner Machine Company and additive manufacturing service provider ADDMAN Engineering Group.

Firstly, VELO3D delivered an aluminum F357-certified metal 3D printing system to Wagner Machine Company to enable the company to serve more customers in the aerospace and defense sectors requiring complex, high-value, and mission-critical parts. Optimized for printing with Aluminum F357, a foundry-grade, high-performance alloy certified for mission-critical applications, VELO3D’s additive manufacturing system provides real-time monitoring of the entire 3D printing process to ensure part consolidation, traceability, and performance.

The second of VELO3D’s partnerships involves ADDMAN Engineering, which has selected an artificial intelligence (AI)-powered “full-stack” laser powder bed fusion (LPBF) Sapphire 3D printing system from VELO3D for the production of parts for the aerospace, defense, and energy sectors. Combined with the company’s integrated Flow design software and Assure quality assurance, the 3D printing system facilitates simpler parts, previously impossible geometries, and shorter print times.

In addition to this, ADDMAN is currently holding two reservations for VELO3D’s new Sapphire XC large format metal additive manufacturing system, which will reportedly provide up to four times the productivity of its predecessor, positioning the firm in good stead to keep up with increasing demand for high-performance space and aerospace parts.

Meanwhile, machine tool manufacturer Cincinnati Incorporated (CI) has entered into a partnership with Ohio State University’s Center for Design and Manufacturing Excellence (CDME) to provide the center with one of its industrial-sized Medium Area Additive Manufacturing (MAAM) 3D printers.

University students and researchers will be able to make use of the machine’s material capabilities, CNC controls, and latest extruder technology to advance their research into polymer and composite 3D printing technologies and techniques.

“CI’s MAAM printer expands the diversity of printers we have to offer at CDME and further differentiates Ohio State as one of the global leaders in additive manufacturing,” said Nate Ames, CDME Executive Director. “The ability to 3D print ULTEM, PEEK, and PEKK at meter-scale opens a new world of manufacturing opportunities.”

Moving away from printers and onto technology partnerships, German 3D printing service bureau FIT AG has signed a development cooperation with electron beam technology specialist pro-beam to create new 3D printing technologies and processes using electron beams. The partnership will explore process, material, and equipment development for additive electron beam technology, as well as expanding its applications to accelerate market-readiness.

Rounding off this week’s partnership updates is the news that Indian 3D printing service bureau Shree Rapid Technologies (SRT) has teamed up with 3D measuring and testing specialist GOM to introduce the company’s scanning and reverse engineering technology to the Indian market.

In the first step to achieving its goal of becoming “India’s only complete digital manufacturing workflow supplier”, SRT will supply GOM’s ATOS Q Blue Light Scanner, Zeiss T-Scan Contact & Non-contact Scanner, Zeiss T-Scan Hawk Handheld Scanner, GOM Scan 1, and Zeiss Reverse Engineering software to the Indian market.

3D printing software releases from Sigma Labs and CoreTechnologie

Quality assurance software developer Sigma Labs has released Version 7.0 of its in-process quality assurance system for metal 3D printing, PrintRite3D. The new version features upgrades to the system’s existing features in addition to new temperature monitoring and calibration functions, recoater interaction detection and predictive models driven by machine learning, multi-laser quality metrics, production framework, and 3D visualization diagnostics.

“We believe the release of PrintRite3D version 7.0 marks a significant milestone in the evolution of in-process quality assurance,” said Mark Ruport, President and CEO of Sigma Labs. “Our commitment to radical collaboration and setting a high-quality standard in 3D metal printing will benefit not only Sigma Labs customers but we expect that it will also help accelerate the growth and prosperity of the entire additive manufacturing industry.”

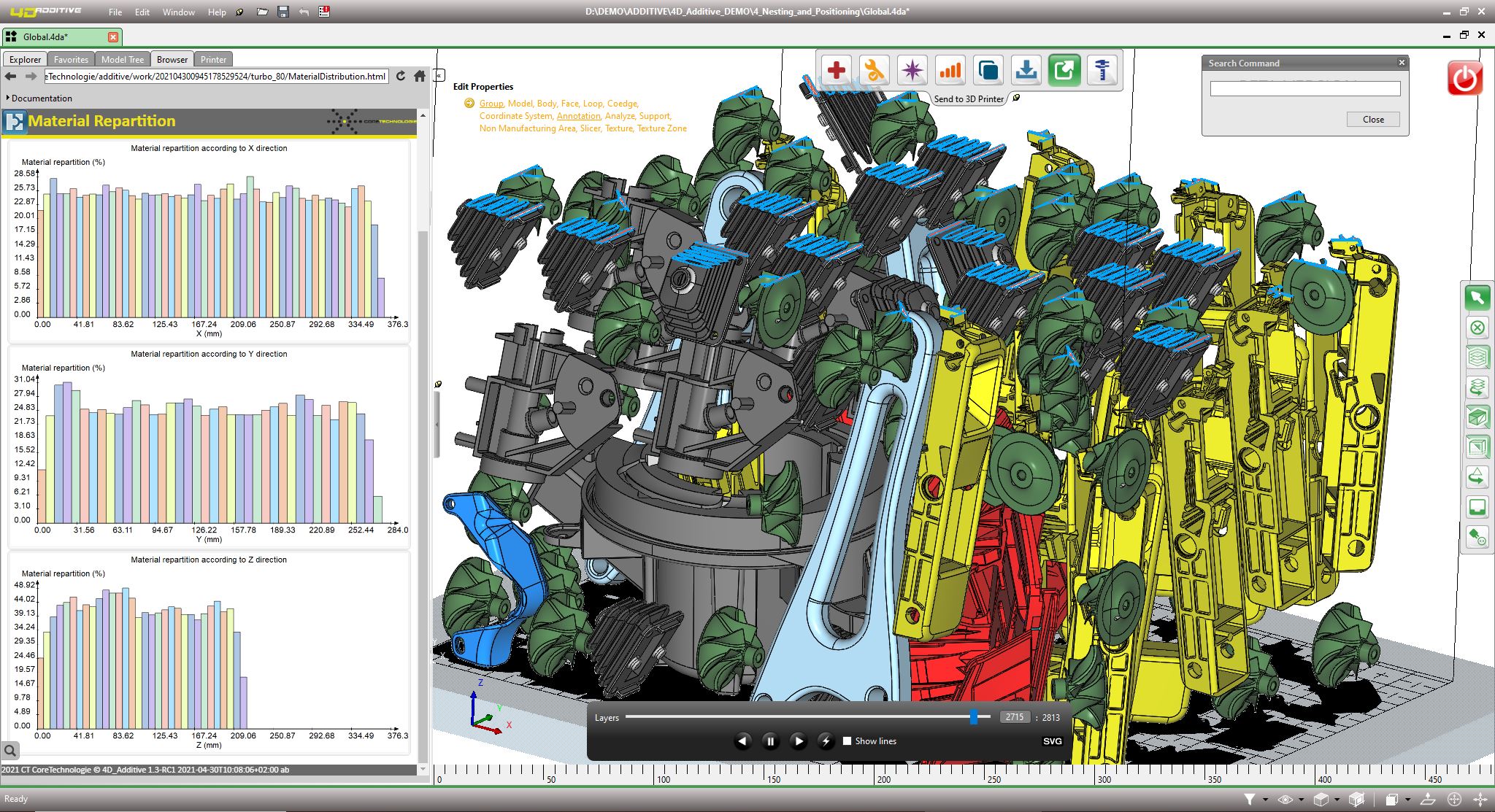

In other software-related news, engineering software developer CoreTechnologie has released the latest version of its 4D_Additive 3D printing software that features new functions to meet the increasing demands of small-batch production of 3D printed parts.

The new features of Version 1.3 include an application programming interface (API) for HP and Photocentric machines that aims to save time by sending slicing data generated on the computer directly to the printer, a revised texture module to enhance the surfaces of CAD models, and improved nesting functions for powder bed machines that optimize filling of the build space. Version 1.3 is also equipped with a new position correlation for SLS and SLM parts to avoid defects, in addition to a time-saving automatic repair function for scan data.

NUBURU awarded blue laser technology patent

High-powered blue laser specialist NUBURU has been awarded a new patent for its blue laser technology, specifically referring to the spatial, polarization and wavelength combination of blue laser diodes to make high power, high brightness blue laser diode systems. The patent adds to the company’s extensive intellectual property (IP) portfolio which has grown substantially throughout the beginning of 2021.

“Our new patent encompasses all methods of combining blue laser diodes for developing high power, high brightness blue lasers,” said Dr. Mark Zediker, Founder and Chairman of NUBURU.

“Winning this landmark patent is another strong testament to our technological leadership across 3D printing and material processing and the innovations we are bringing to the industry.”

3D printing awards and events announcements from Lab of the Year, QEPrize and Gardner Business Media

Moving onto the topic of awards, and the Science Foundation Ireland’s (SFI) Centre for Doctoral Training in Advanced Metallic Systems (AMSCDT) has won the Education Laboratory of the Year Award from the 2021 Irish Laboratory Awards. AMSCDT is formed out of a partnership between the University of Sheffield, University of Manchester, University College Dublin, and Dublin City University (DCU), which promotes research and industry engagement through its state-of-the-art metallurgy and laser processing facilities.

“The UK and Ireland has a critical shortage of doctoral level metallic materials specialists, which impacts on our competitive manufacturing capabilities,” said Professor Dermot Brabazon at DCU. “In the center, we deliver four-year doctoral projects with technical and leadership training for STEM graduates. The projects are designed specifically for and with industry, to support high-value manufacturing across the whole supply chain, from fundamental research through to industrial delivery.”

Elsewhere, the Queen Elizabeth Prize for Engineering (QEPrize) has opened up its public nominations window. The QEPrize is awarded to up to five engineers from around the world and across all sectors of engineering that are responsible for “groundbreaking engineering innovation of global benefit to humanity”.

“The global pandemic has demonstrated just how rapidly the work of engineers can have a widespread and demonstrable impact on our lives,” said Lord Browne of Madingley, Chairman of the QEPrize Foundation. “As the nature of engineering and society’s expectations of engineering continue to evolve, so too does the QEPrize. Our move to an annual award reflects this pace of change.

“It will enable us to celebrate the pinnacle of engineering achievement, and to honor more engineers whose work improves the lives of so many people around the world.”

Regarding events, Gardner Business Media and its media brands Plastics Technology, MoldMaking Technology, and Additive Manufacturing, are launching a new trade show for the North American plastics processing market next year, called The Plastics Technology Expo (PTXPO). The event will debut between March 29-31 2022 at the Donald E. Stephens Convention Center in Rosemont, and will run annually except during NPE years.

Dimension Inx awarded grant for regenerative medical products

Dimension Inx, a biofabrication firm from Chicago, has been awarded $240,000 funding from the US Department of Defense (DoD) to develop a regenerative medical device capable of repairing tracheal injuries. The project will leverage the company’s patented biomaterials platform to create implantable constructs that emulate the microenvironment of the trachea, and combine them with a novel hydrogel to support remodelling into normally functional tracheal tissue.

“Our technology platform allows us to create unique, microstructurally-driven materials and structures that account for the complex multi-tissue environment of the trachea,” said Dr. Adam Jakus, Dimension Inx Chief Technology Officer. “This is critical for promoting healthy tissue regeneration and restoring the original tissue functions.”

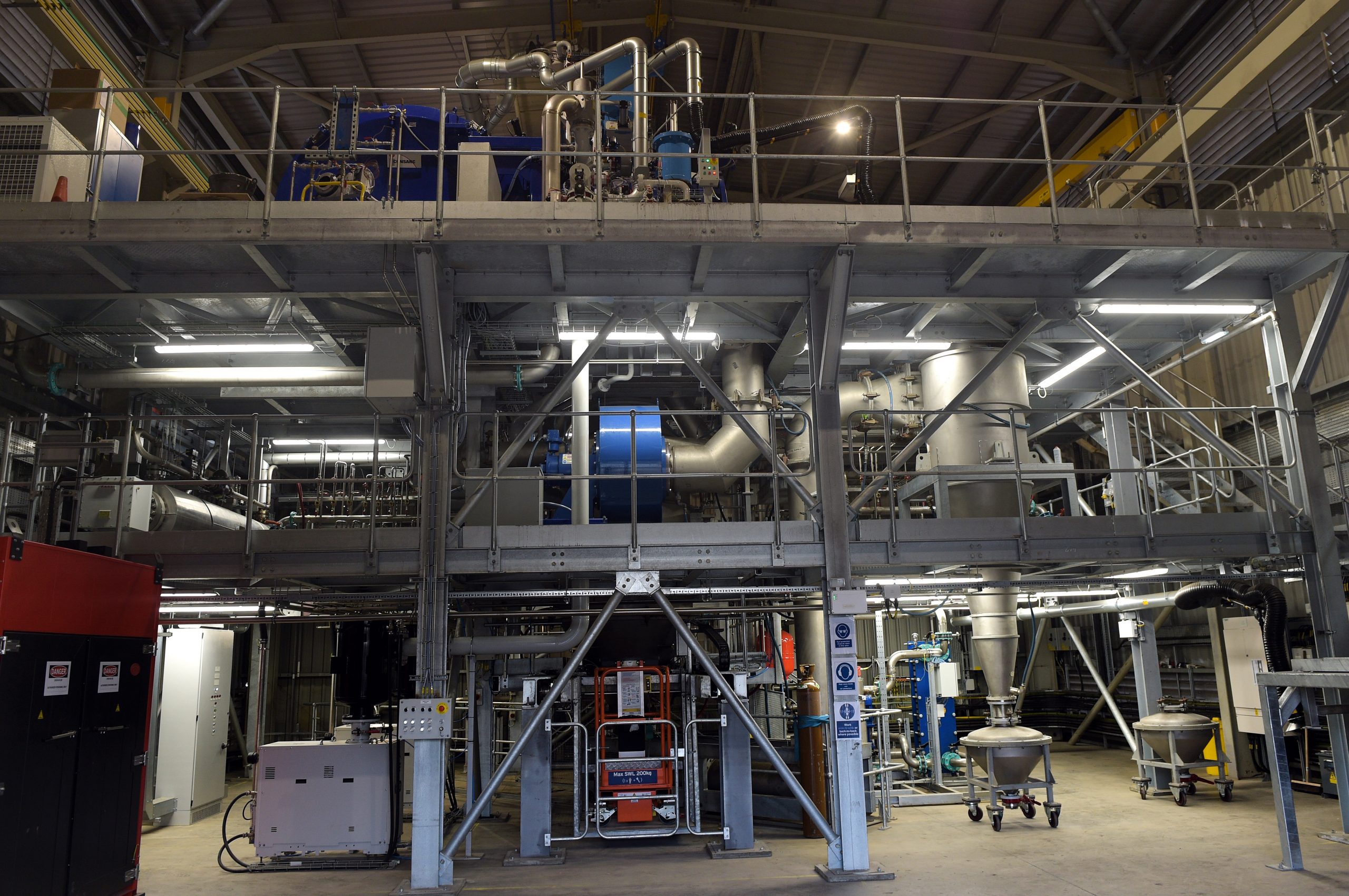

LIBERTY Powder Metals awarded two quality certifications

LIBERTY Powder Metals, owned by industrial metals company LIBERTY House Group, has received two quality certifications for the manufacture, processing, and testing of its metallic alloy powders for near net shape and additive manufacturing applications. The company’s quality management system (QMS) was awarded the EN 9100 internationally-recognized QMS certification for the aerospace industry, and the ISO 9001 equivalent certification for general industry.

“These certifications confirm the quality of our world-class manufacturing processes and demonstrate our commitment to high-quality working practices,” said Dermot Desmond, LIBERTY Powder Metals’ Commercial and Business Development Manager. “Achieving this against the backdrop of the Covid-19 pandemic is testament to the dedication of all our staff and partners, enabling the business to push forward and start operating at full capacity.”

New 3D printing developments in space and automotive

The Satellite Applications Catapult has added a MetalFAB1 3D printing system from the Netherlands-based 3D printing firm Additive Industries to its Disruptive Innovation for Space Centre (DISC). The system, which will be available for UK companies to use from July, will be used to showcase the potential of additive manufacturing for the space sector, with a particular focus on rocket engines.

The MetalFAB1 will be leveraged to deliver weight saving, novel geometries, low volume production requirements, and reduced part count offerings to businesses looking to manufacture aerospace parts. The machine will be available for firms to use on a pay-as-you-go basis and its installation aims to remove the barriers to growth for the UK’s space industry.

“The surge in the number of companies aspiring to build and support new launch vehicles and in-space propulsion continues to grow,” said Mike Curtis-Rouse, Head of Manufacturing for Space at the Satellite Applications Catapult. “This new capability will ensure that UK SMEs can access the latest in additive manufacturing technology to accelerate their businesses, prove new processes and learn first-hand the skills needed to fully exploit the phenomenal technology that the MetalFAB1 delivers.”

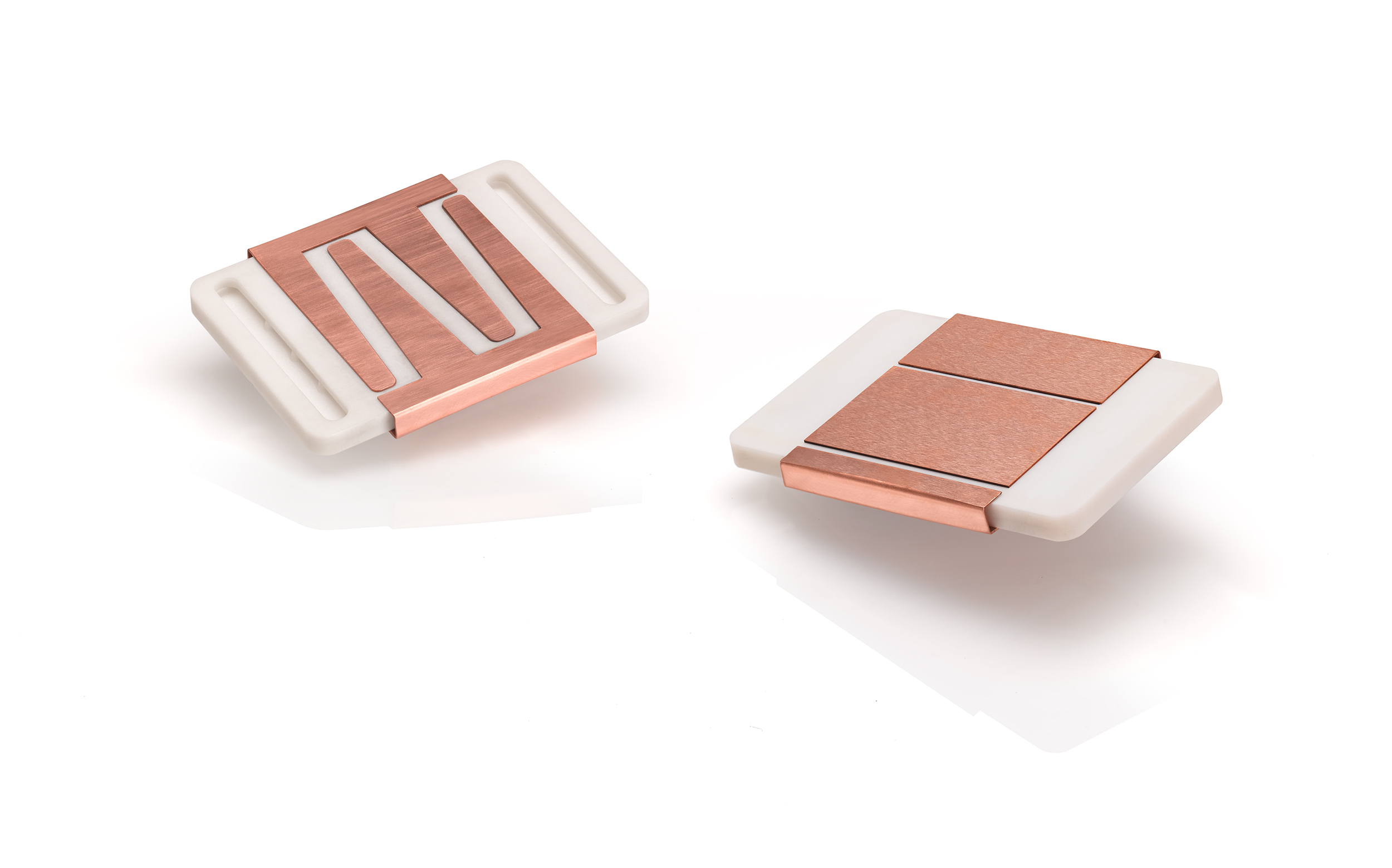

Crossing over to automotive and e-mobility, and ceramic specialist CeramTec has unveiled a new ceramic-based power semiconductor module designed to play an important role in cooling power electronics within powertrains.

The company has developed a ceramic cooler with applied metallization for the thermal management of drive inverters, which convert energy from the vehicle battery, allowing silicon carbide (SiC) semiconductor chips to be applied directly to the ceramic cooler, dubbed ‘chip-on-heatsink’. The power module ensures the efficient cooling of the SiC chip so that its surface area can be optimally utilized. The project was developed jointly with the Fraunhofer Institute for Integrated Systems and Device Technology (IISB).

Wall Colmonoy launches new Wallex powder range for dental

In other news, metal specialist Wall Colmonoy has released a new range of Wallex Cobalt Chromium Powders and Cast Discs suitable for applications in the dental sector. The powders are available in three main chemistries – CoCrMo, CoCrW, and CoCrMoW – and can be used in the 3D printing of dental implants, partial dentures, and prosthetics.

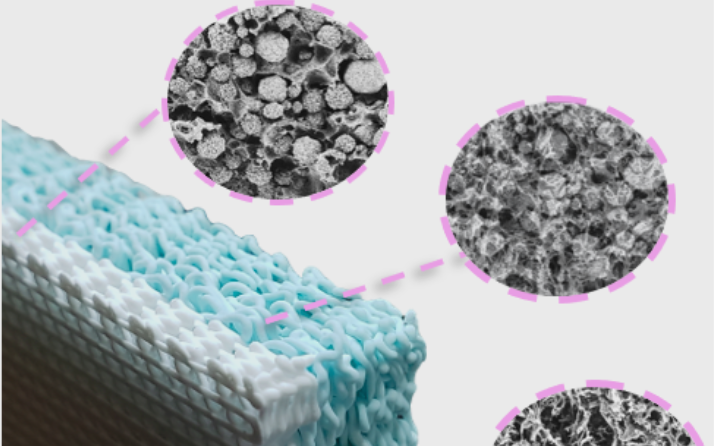

The CoCr powders are produced in the company’s dedicated alloy processing cell, are perfectly spherical, and are engineered to deliver excellent flowability. They offer high-particle density, are nickel-free, and have very low oxide content. Wall Colmonoy has also developed a powder/binder composite that can be used to produce ‘Soft-Block’ technology, which is a much softer form of disc that is pre-sintered before machining and then sintered again at full temperature.

First 3D printed smart lamp in the Middle East

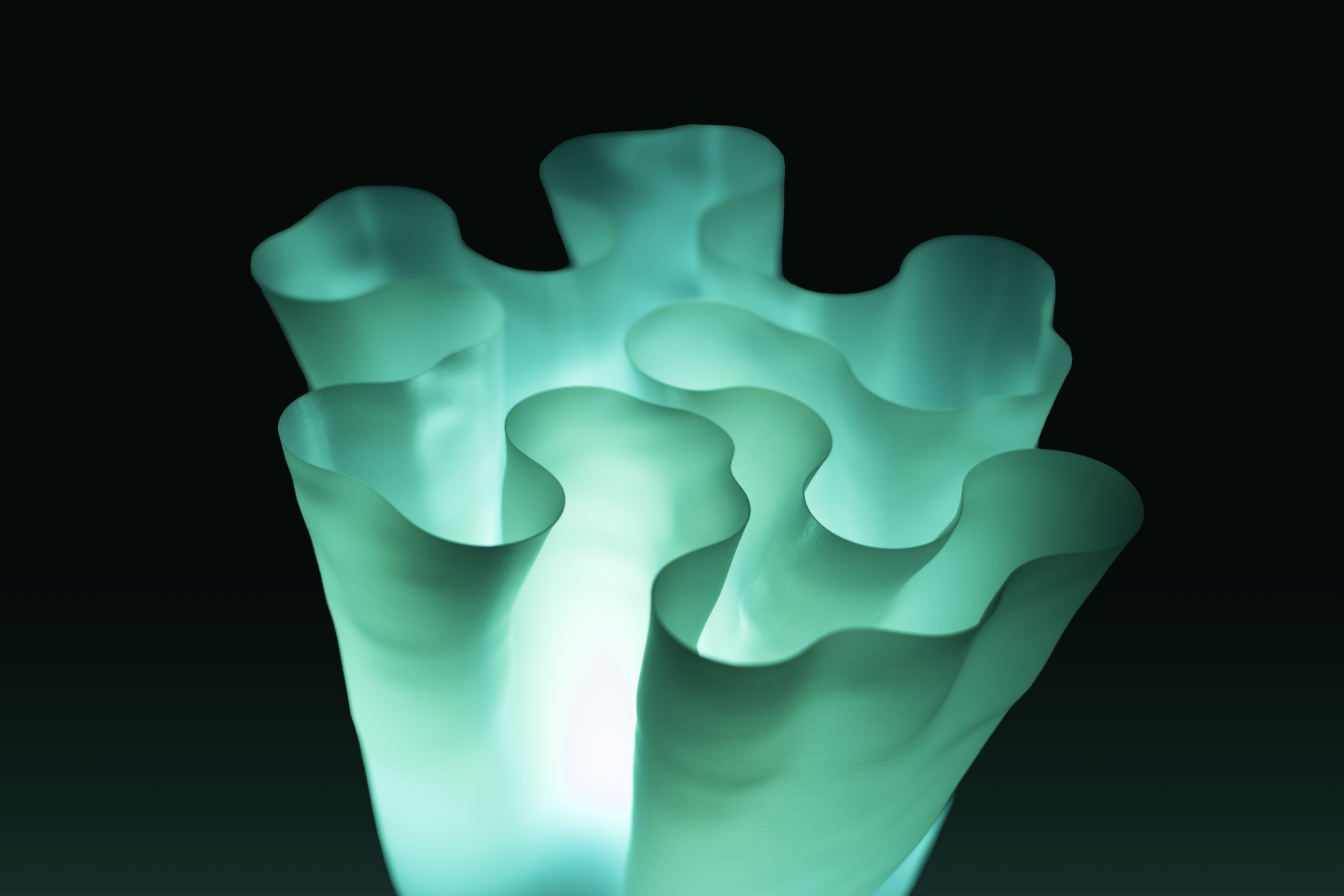

Rounding off this week’s roundup is a new collection of Egyptian Lotus flower-inspired 3D printed smart lamps, Ward, from Khawarizm Design Studio. Ward, the Arabic word for flowers, reflects the concept behind the collection’s design which uses the Lotus flower as a symbol of ‘purity, enlightenment and self-regeneration’.

The Khawarizm team used 3D printing and recycled PLA filaments to create the Ward collection of futuristic lighting fixtures, which are equipped with Internet of Things (IoT) technology and are compatible with common virtual home assistants, like Amazon’s Alexa. According to the team, the Ward collection represents the first 3D printed smart lamp in the Middle East, acting as a ‘perfect analogy for the human condition’.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed lamp from the Ward collection by Khawarizm Design Studio with the Sliced logo.