In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features a new wave of market expansions, landmark 3D printer installations, corporate takeovers, qualified jewelry materials and an upcoming additive manufacturing-enabled Russian ‘superjet.’

Read on for the most recent updates from GE Additive, Inkbit, Pyrogenesis, Tritone Technologies, Altair, Gen3D, Ai Build and more.

Acquisition, funding and financial updates

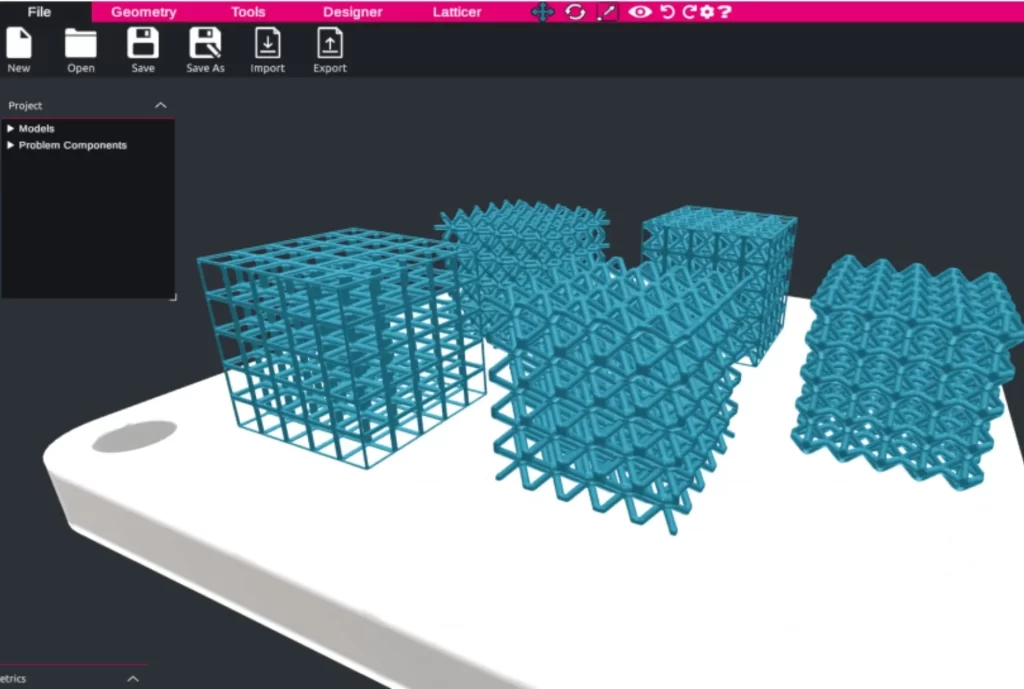

Kicking off this week’s round-up with a slice of business news, 3D design and simulation software developer Altair has announced the acquisition of Gen3D. Spun-out of the University of Bath, the start-up has developed a technology that uses implicit modeling techniques to enable the rapid creation of complex parts, which would otherwise be impractical to realize via traditional BREP modeling.

According to Altair Founder and CEO James R. Scapa, buying Gen3D is not only expected to enable this technology to be integrated into the Altair Inspire platform, but to see his firm inherit a team packed with “industry knowledge and experience,” in generative design, topology optimization and lattice structure generation.

Meanwhile, on the funding front, Ai Build has successfully raised $3.2 million via a seed investment led by ACT Venture Partners, and supported by long-term backer SuperSeed. Using the capital raised, the company reportedly intends to ramp-up its efforts to develop machine learning models that provide automated quality assurance, and widen the adoption of its software among 3D printer users.

“This is a time when manufacturers are looking to realize the potential that additive manufacturing offers, making their supply chains more flexible, resilient, cost-effective and sustainable,” said Mads Jensen, a Managing Partner at SuperSeed. “Ai Build enables its customers to rapidly achieve these strategic objectives through its groundbreaking 3D printing software.”

Lastly in this edition’s business update, wide-format inkjet printer manufacturer Mimaki has revealed that it achieved an increase in its market share in FY 2021. This was particularly the case in the firm’s Sign Graphics segment, where it even saw growth on the pre-COVID FY 2019, but its 3D printing division is also set to ‘take strides forward,’ thanks in part to launches like its new MH-110PCL material.

“2021 has been an exceptional year for Mimaki and we’re very proud to have been able to support our customers,” said Arjen Evertse, GM of EMEA Sales at Mimaki. “With numerous new additions to our portfolio, many of which were on show at FESPA, we aim to bring even further benefits and new opportunities to the markets we serve, and we are extremely excited to see what the rest of 2022 will bring.”

New wave of distributors revealed

Moving onto the latest distribution deals now, Israeli reseller SU-PAD has signed an exclusive distribution agreement with Tritone Technologies. In the aftermath of the deal being signed, Omer Sagi, VP of Products and Business Development at Tritone, revealed that his firm has chosen specifically to work with SU-PAD, due to its “experience, expertise and high-quality service level in the AM field.”

Likewise, 3D printer manufacturer and service provider Prodways has sought to expand the reach of its business, via the agreement of a new distribution partnership with Dental Axess. Moving forwards, the company believes the deal will enable it to better address the dental sector’s big players, while reinforcing its presence in North America and Europe, and providing it with a foothold in the Australian market.

“Prodways’ printers offer customers a next level printing experience when it comes to scaling up digital manufacturing in the dental industry, especially in the clear aligner sector,” explained Per Claesson, CEO of Dental Axess. “The unique ability to print dozens of models within minutes, while achieving superior precision even for the most demanding applications, will allow us to serve our customer base who is experiencing strong growth and needs to move to larger systems.”

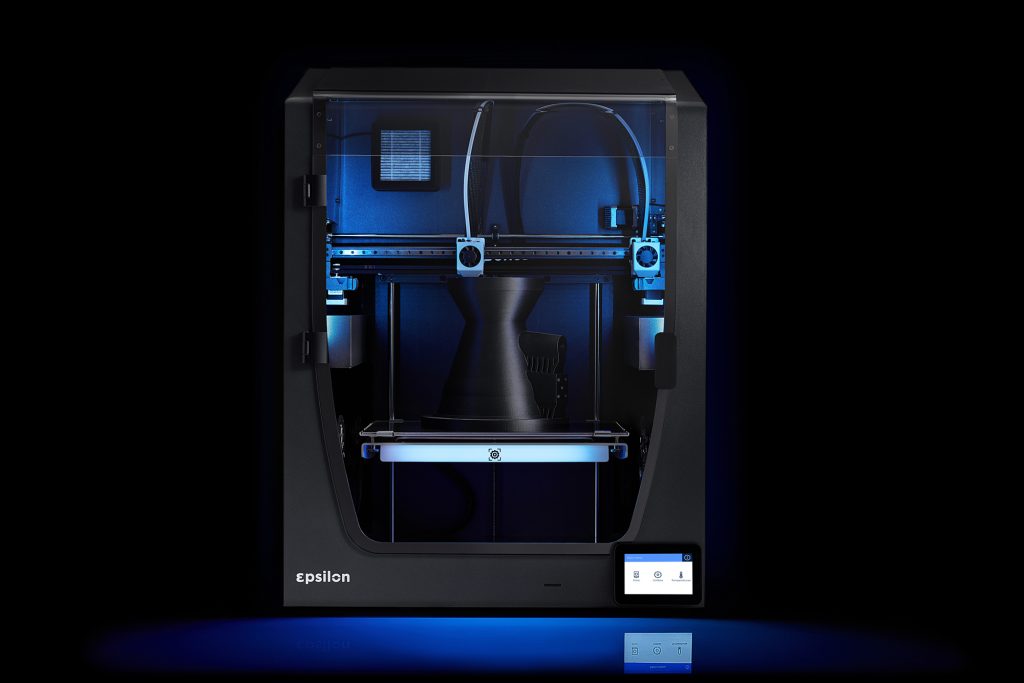

Spanish 3D printer manufacturer BCN3D has also announced a collaboration with 3Dwiser, that’ll see its portfolio, including its flagship Epsilon W50 3D printers, being offered to more customers in the Czech Republic. While 3Dwiser has hailed the “immediate and easy-to-use” nature of the products it can now offer clients, BCN3D CEO Xavier Martínez Faneca says the deal reflects his firm’s “rapid growth.”

“3Dwiser is an extremely experienced and well-respected distributor of 3D Printing equipment,” Faneca said of the partnership. “We are very excited to be partnering with them and I think that BCN3D customers in the Czech Republic, Slovakia, and Hungary will be well served by their knowledgeable team.”

Inkbit and Roboze in landmark shipments

In sales news, Massachusetts-based 3D printer manufacturer Inkbit has passed a significant landmark, by shipping its first-ever Vista Production system. Having now been installed at Saint-Gobain’s Research Cross-Business R&D Center, the machine will be used to develop processes and products for businesses across various different industries.

“We are pleased to announce that our first Vista platform system is operational at Saint-Gobain’s Research Center,” said Davide Marini, Co-founder and CEO of Inkbit. “This is an important milestone for Inkbit: an idea conceived in an academic laboratory at MIT is now a commercial manufacturing system operating outside our building.”

“We are thrilled to be working with Saint-Gobain at exploring novel applications of our technology.”

Elsewhere, in a similarly significant installation, Matsuura Machinery has fitted Roboze’s machines at its AMC in Leicestershire. The systems have been shipped there as part of a new deal between the firms, which will see Matsuura represent Roboze in the UK, with a view to expanding its market there.

“Manufacturing companies, now more than ever, need the necessary tools to cope with the important global digital and green transitions taking place,” explains Giancarlo Scianatico, EMEA Business Development Director at Roboze. “Given Matsuura’s leading position in the UK manufacturing supply chain, we know that Roboze is in safe hands in the growing UK market for additive manufacturing technology.”

Material moves from Desktop Metal and Pyrogenesis

Plasma atomization specialist Pyrogenesis has announced a 100-kilo shipment of titanium powders, its second such delivery in as many weeks. Following what Massimo Dattilo, VP of PyroGenesis Additive, calls a “long and exacting journey,” he says the firm is now positioned to push the boundaries of its technology even further, and target the “production of powders by the tonne.”

In other material news, industrial 3D printer manufacturer Desktop Metal has successfully qualified 925 sterling silver on its Production System. In doing so, the company has made the popular precious metal, ideal for producing jewelry, watches, belt buckles and decorative pieces, a viable 3D printing material for P-1 and P-50 users.

The qualification, which builds on Desktop Metal and ETEC’s long history of working with jewelry producers like Cartier, Stuller, Shinola and Swarovski, is likely to be the first of many, with the former already working on 18K yellow gold and rose gold.

“The qualification of precious metals for direct 3D printing on high-speed binder jetting systems is a major milestone for the jewelry and luxury goods industry,” said Ric Fulop, Founder and CEO of Desktop Metal. “All the design freedom and customization of 3D printing can now be delivered directly at high volumes without all of the labor associated with traditional manufacturing processes.”

Advances in clinical and aerospace AM

Rounding-off this week’s update with application announcements, Russia’s United Engine Corporation has begun developing two experimental engines for the Sukhoi Superjet 100 aircraft. The engines, which are being designed to help truly realize the Kremlin’s ambitions of a ‘superjet,’ have a $1.83 billion budget, hence the firm is seeking to expand its adoption of 3D printing, to reduce their production cost.

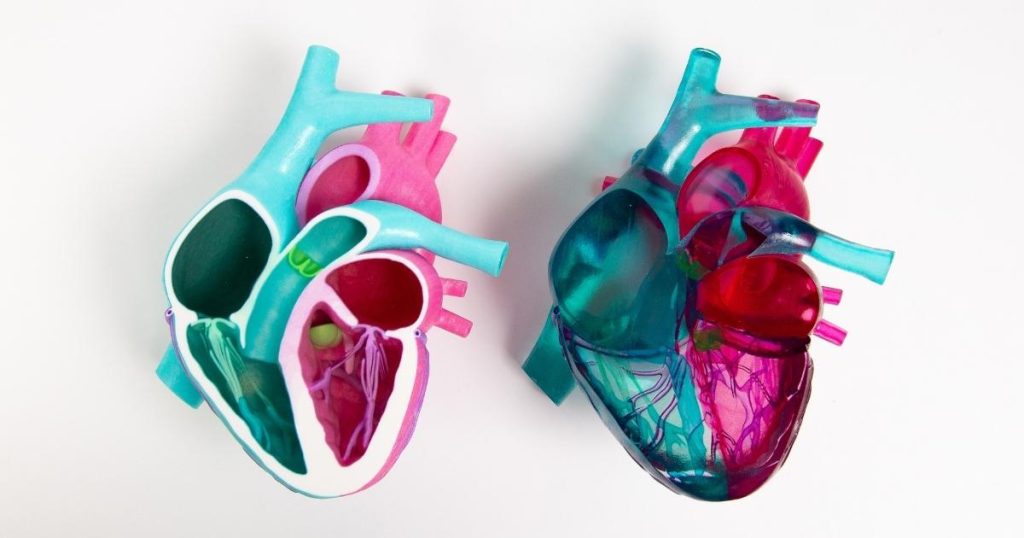

To drive additive manufacturing’s adoption in the medical industry, meanwhile, GE Additive has partnered with orthopedic implant specialist Orchid Orthopedic Solutions. As part of the companies’ collaboration, Orchid plans to invest in GE Additive’s Spectra L systems, AP&C powders and AddWorks consultancy services, with the units set to be fitted in 2022, and become ready for operation by 2024.

As well as installing these EBM technologies at Orchid’s facility, the firms have also committed to conduct ‘joint co-marketing activities,’ with the aim of driving greater awareness around their large orthopedic implant 3D printing capabilities.

“Together with our extensive knowledge of large joint orthopedic manufacturing, we will be able to serve customers like never before,” explained Nate Folkert, CEO of Orchid Orthopedic Solutions. “They will have the assurance that we are taking an extra level of care by partnering with GE Additive. I look forward to seeing Orchid drive continued additive manufacturing innovation as a result of this agreement.”

“We are thrilled to collaborate with GE Additive to bring additive manufacturing capabilities to our customers.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on the Sukhoi Superjet 100 aircraft. Photo via Russian Aviation Insider.