In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new 3D printing partnerships and business updates, new additive manufacturing materials, updates from the construction field, and 3D printed fire-fighting drones.

Read on for the most recent updates from Freemelt, Prototek, Hawk Ridge Systems, Axle Box Innovations, Rocket Lab, Boston Micro Fabrication, and more.

Business updates from Stratasys, Freemelt, Prototek, E3D, and Hawk Ridge Systems

Kicking off this week’s business news is 3D printer manufacturer Stratasys, which has introduced a new loyalty and discount program for its service bureau customers. The Stratasys Parts Provider Network (PPN) will provide access to volume discounts on the firm’s systems, materials, service contracts, and software, as well as wholesale pricing for on-demand parts printed through its Stratasys Direct Manufacturing arm.

“Stratasys recognizes the integral role service bureaus play in transforming global manufacturing, and our Parts Provider Network demonstrates our commitment to supporting their unique business needs,” said Pat Carey, Senior Vice President of Strategic Growth for Stratasys. “With five additive manufacturing technologies, we can provide PPN members with access to a robust portfolio of solutions to expand their offerings, increase their market share and provide their end customers with solutions to meet their additive manufacturing goals.”

Meanwhile, Swedish 3D printer manufacturer Freemelt has received an order for one of its Freemelt ONE systems for the University of Maribor in Slovenia. To be delivered in the third quarter of 2022, the system is the first to the Slovenian market and will be used for research on materials for orthopedic implants.

Elsewhere, 3D design and manufacturing reseller Hawk Ridge Systems opened the doors to its new additive manufacturing center in the Santa Clara Valley in a move to bolster its production capacities.

“We are excited about moving our Digital Manufacturing Lab to a more spacious and accommodating facility,” says Paul Rudin, VP of Digital Manufacturing for Hawk Ridge Systems. “Displaying our additive solutions is important in order to demonstrate their value, features and capabilities to our clients – and this space allows us to do just that.”

Onto acquisition news now, and on-demand manufacturing service provider Prototek has completed its purchase of Pennsylvania-based 3D printing service bureau ProtoCAM. The latter will merge into Midwest Prototyping, Prototek’s additive manufacturing arm acquired in July last year.

Through the deal, Prototek will gain access to ProtoCAM’s QuickCast technology, which enables the creation of rapid investment casting patterns for metal part production, while the merger will also increase the capacity of Midwest Prototyping’s core 3D printing technologies.

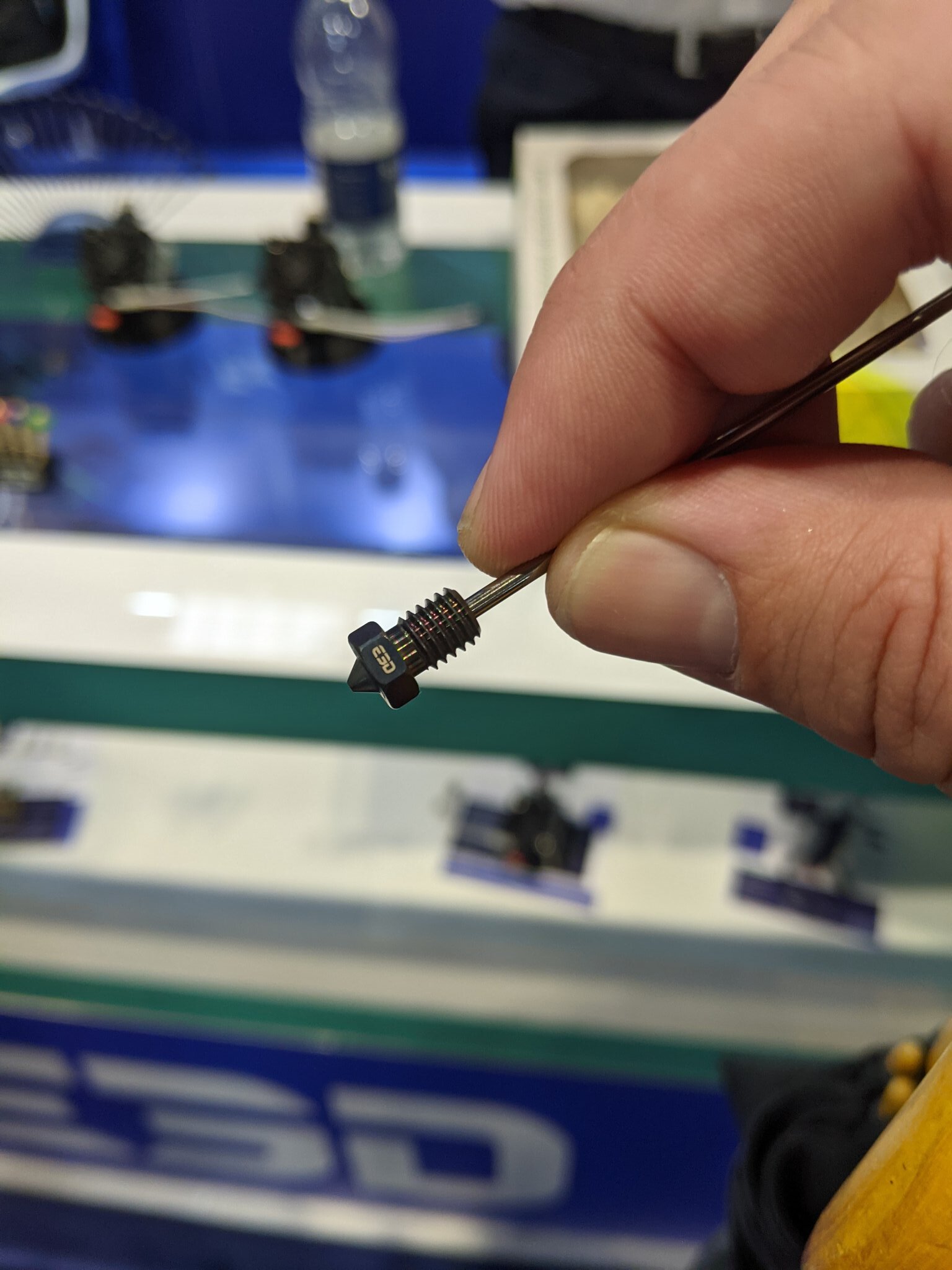

Additionally, 3D printing hardware manufacturer E3D has announced the acquisition of nozzle and aftermarket parts provider ZODIAC 3D. The deal will enable E3D to increase its supply chain stability for all product lines and the company plans to grow ZODIAC 3D’s current product lines of specialty nozzles and other accessories.

“I am personally thrilled to be introducing the ZODIAC product line to E3D customers, both current and new,” said Clare Difazio, Head of Product Strategy and Marketing at E3D. “Their high quality offering complements the E3D brand and means we have confidence to back the ZODIAC name. I look forward to bringing this brilliant range of aftermarket upgrades to an even wider range of printers than we supply for today.

“For us, it means we can be assured that great quality extrusion is more accessible than ever. The future of AM is exciting, and we’re here for it.”

New 3D printing partnerships from Rocket Lab, Boston Micro Fabrication, and COBOD

California-based aerospace firm Rocket Lab has entered into a partnership with NASA to manufacture the solar array panel that will power the latter’s GLIDE mission, which will study the area where the Earth’s atmosphere meets space.

To manufacture the solar array panels, Rocket Lab will leverage the technology of its recently acquired satellite solar array panel supplier SolAero to provide the Z4J quadruple junction solar cell designed specifically for space applications. Fully qualified for space, the Z4J is a high-efficiency, radiation-hardened solar cell laid on carbon composite facesheet panels.

Meanwhile, microscale 3D printing systems specialist Boston Micro Fabrication (BMF) has partnered with Australian reseller AXT to provide the Australian and New Zealand markets with access to its ultra-high resolution 3D printers.

“Our 3D printers have gained excellent acceptance around the world in areas such as medical devices, electronics, microfluidics and MEMS to name but a few,” said Chris Jianlin Zhou, General Manager of the Asian Pacific Business Unit of Boston Micro Fabrication.

“Expanding into Australia where technology is rapidly accepted was a natural progression for us and we are pleased to partner with AXT for this next stage in our growth.”

Elsewhere, construction 3D printing specialist COBOD has brought Australian firm Fortex on board as a distributor, meaning its construction additive manufacturing technology is now available in six continents. Through the deal, COBOD hopes to strengthen construction 3D printing in the Asia-Pacific region, with the first BOD2 machine arriving in Australia in Q4 2022.

“We are very proud to be partnering up with Fortex to bring our state-of-the-art 3D construction printing technology to Australia,” said Simon Klint Bergh, Head of Asia Pacific for COBOD. “This arrangement, together with our new distribution partners Siam Cement in Thailand and KA Bina in Malaysia, and our new regional office in Malaysia, will mean that we will penetrate the growing market in Asia-Pacific even further.”

New materials from Microlight3D and Filaticum

Onto new materials now, and microscale 3D printer manufacturer Microlight3D has launched eight new resins developed for mechanical meta-materials and life sciences applications. Containing flexible, rigid, and biocompatible resins, the range will allow developers to explore 3D microprinting using different materials to reproduce complex, minuscule objects.

For the mechanical metamaterials field, the range includes two rigid resins, Rigid-A and Rigid-E, as well as a flexible resin, Flex-A, which are suitable for 4D printing and micromechanics applications like micro-grippers and screws. A fourth resin, OrmoRed, is designed for use with an infrared laser and can be enhanced with metallic or magnetic nanoparticles.

Of the other materials in the product line, OrmioBio and Green-A-Bio are biocompatible resins, while Green-Gel and UV-Gel are biocompatible and ductile hydrogels.

Elsewhere, a rather distinctive surface is now offered by Hungarian-based industrial filament manufacturer Filaticum’s new 3D printing material. The PLA-based Filaticum Fuzzy filament is designed to create objects with a fluffy, fuzzy surface, while maintaining high impact resistance and undergoing post-processing without hitch.

Construction news from Thinking Huts and DELTASYS E FORMING

The first of this week’s construction-related news comes from non-profit Thinking Huts, which has constructed the first in a planned series of 3D printed schools to solve Madagascar’s school shortage. The first of the 3D printed schools is located in Fianarantsoa in south-central Madagascar, and is built in a basic honeycomb shape measuring around 700 square feet.

Printing the walls of the school took about 18 hours, after which a wood roof, door, and windows were installed. In total, the project took three weeks to complete, and saw the involvement of 14Trees, a joint venture between LafargeHolcim and CDC Group, which built the world’s first 3D printed school in December 2020.

3D printer manufacturer DELTASYS E FORMING, meanwhile, has successfully delivered and installed a concrete 3D printer at the Indian Institute of Science (IISc) in Bengaluru. The printer will be used to research various sustainable materials for concrete 3D printing, and is the latest in a string of investments made by educational institutes in construction additive manufacturing.

New research studies oxide growth on 3D printed metals

A joint study by Southwest Research Institute and Sandia National Laboratories has investigated the differences in oxide film growth on 3D printed metals in a supercritical CO2 environment. The team exposed samples of both additively manufactured metals and traditional wrought stainless steels to a simulated supercritical CO2 power cycle environment, including a temperature of 450 degrees Celsius and pressure of 76 bar, for two weeks.

According to the researchers, both types of metals showed oxide growth, however while the oxide covered 72% of the wrought stainless steel, it only covered 54% of the 3D printed metal. Although the data suggests that 3D printing process should be optimized for these types of conditions going forwards, the researchers said their study doesn’t prove that one is more reliable than the other.

3D printed fire-fighting drones

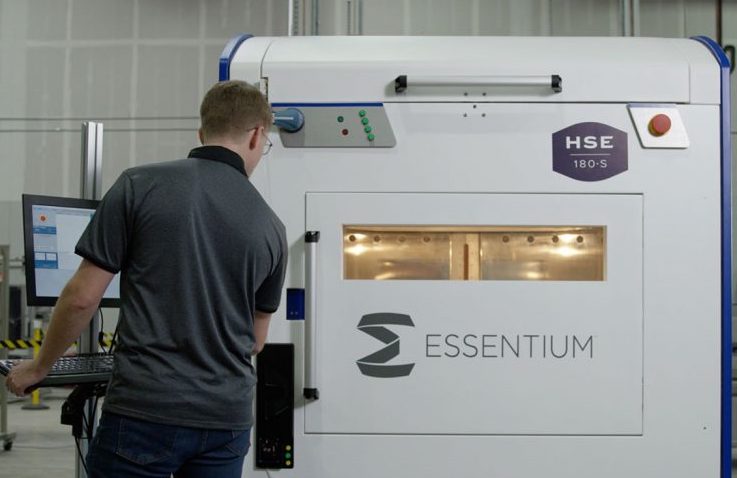

Technology from Essentium, the OEM behind High Speed Extrusion (HSE), is being leveraged by public safety technology developer Axle Box Innovations to develop 3D printed drones for fire management and protection. The firm is utilizing Essentium’s HSE 3D Printing Platform and high-performance materials to accelerate the development of lightweight and robust drone bodies capable of surviving the extreme heat profile of wildfires to support the efforts of emergency response teams.

Axle Box Innovations turned to 3D printing to overcome the strength, speed and cost obstacles of developing bespoke fire-safe drones. According to the company, the 3D printed drones exceeded expectations during demo flight testing regarding their high-speed impact and overall functionality.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows Filaticum Fuzzy 3D printed owl with the Sliced logo.