In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new 3D printing partnerships and business updates, new additive manufacturing materials, and a “world’s first” 3D printed cycling component.

Read on for the most recent updates from Nano Dimension, Nexeo Plastics, Oqton, Mimaki, Metron Additive Manufacturing, and more.

New 3D printing partnerships from Nexeo Plastics and Oqton

Beginning this edition of sliced is thermoplastic resin distributor Nexeo Plastics, which has signed an agreement with Highsun Engineering Plastics to distribute the firm’s 3D printing resins throughout the Americas.

Highsun’s resins are suited for mono and multilayer film applications that require thermoformability and chemical and puncture resistance, alongside an improved oxygen and aroma barrier. In particular, the resins are ideal for compounding, extrusion, and blow molding processes.

“Highsun and Nexeo Plastics’ synergistic competencies will create a valuable platform for our accelerated growth in the Americas,” said Stanly Tan, Business General Manager at Highsun Engineering Plastics.

“This partnership will see us harnessing the strength of Highsun’s world-leading polyamide polymerization capabilities and Nexeo Plastics’ integrated supply chain and its local network and relationships.”

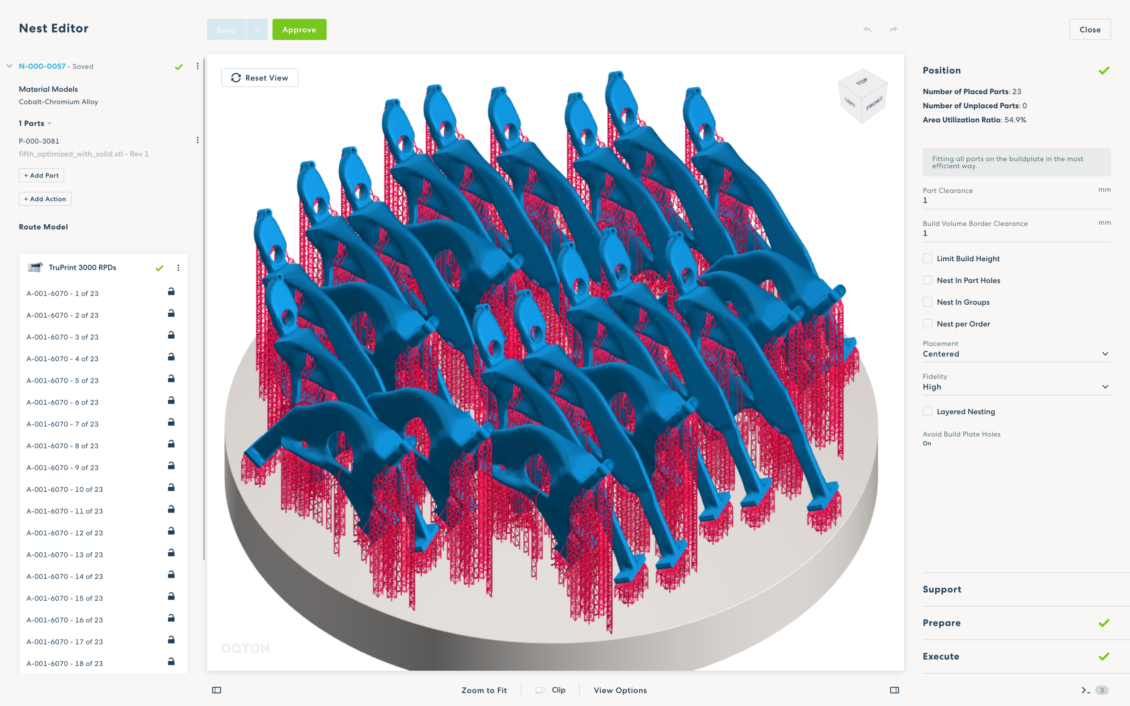

Meanwhile, artificial intelligence (AI) software firm Oqton has entered into a strategic partnership with 3D printer manufacturer Eplus3D to advance the adoption of dental 3D printing. Through the partnership, the companies are seeking to enable dental laboratory professionals to increase their productivity and provide a better service to their customers.

To this end, Oqton’s AI-powered manufacturing OS end-to-end platform will be made available to users of Eplus3D’s metal 3D printers in order to deliver full traceability and automation from initial design through to preparing files for production.

Nano Dimension launches share repurchase plan

Elsewhere, additively manufactured electronics (AME) specialist Nano Dimension has initiated a one-year share repurchase plan allowing the company to invest up to $100 million to repurchase its American Depository Shares (ADSs).

The repurchase plan authorizes Nano Dimension’s management to repurchase ADSs from time to time in both open market and privately negotiated transactions, and can be terminated or suspended at any time.

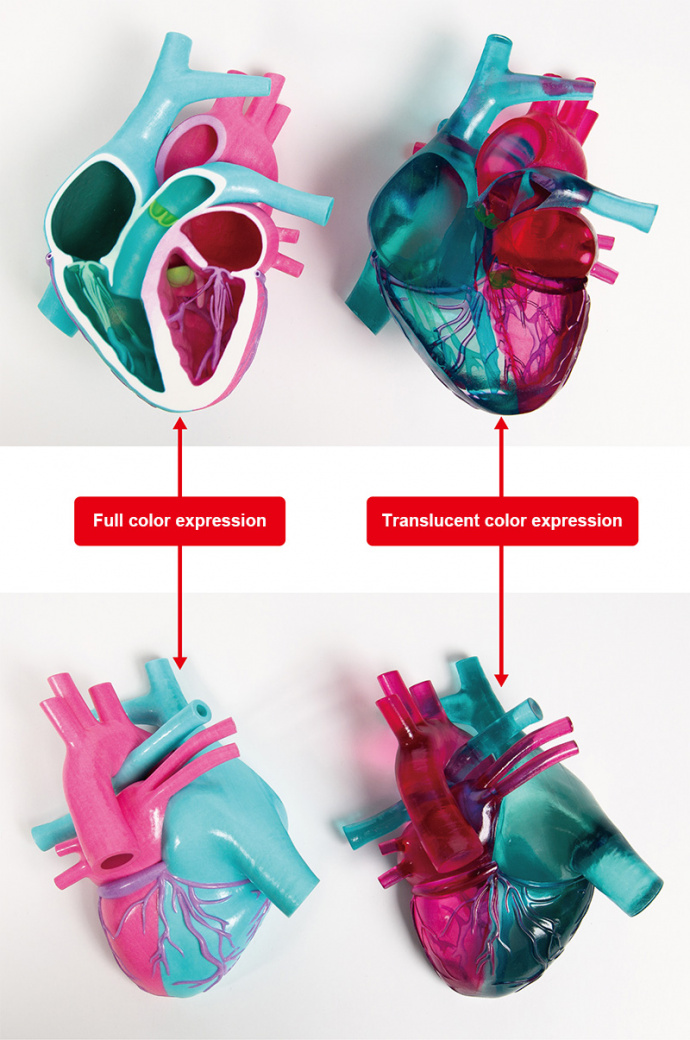

Mimaki unveils new pure clear ink for transparent modeling

Wide-format inkjet printer and cutter manufacturer Mimaki has released a new Pure Clear MH-110PCL ink intended for use with its 3DUJ-553 full-color 3D printer. The ink is designed to eliminate the yellowish tint evident in previous MH-100CL clear inks to enable more transparent modeling for applications such as home appliances, cosmetics, and medical and architectural models.

As well as its clear output, the Pure Clear MH-110PCL can also be combined with color inks to reproduce translucent color effects, particularly desirable within practical medical models. Pure Clear MH-110PCL is available in 4.8-liter capacity ink bottles from May 2022.

The “world’s first” 3D printed cycling stem

Rounding off this week’s news roundup is engineering consultancy Metron Additive Manufacturing, which has launched what it claims is the “world’s first” commercially-available 3D printed stem through its new cycling components wing, Mythos.

The Elix stem is designed to provide increased “usable stiffness”, with 3D printing enabling Mythos to engineer the component with a lattice-like design that reinforces specific areas of the component while decreasing weight in others. As a result, the company could eliminate areas of high stress with small local reinforcements and remove non-essential material from the stem.

The stem was 3D printed via selective laser melting (SLM) in Scalmalloy, a 3D printing-specific material made from scandium, aluminum, and magnesium and developed by engineers at Airbus. Set to become the first commercially available 3D printed bike stem for general public use, the Elix stem will be priced at a hefty £500 and pave the way for additional 3D printed components from Mythos in the future.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows the Mythos Elix stem with the Sliced logo.