In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions across the additive manufacturing industry.

Today’s edition also features the Multimaterial Dryer from Kodak’s Smart International and Copper3D’s potential solution for bacterial infections when wearing 3D printed prostheses.

Read on for the latest 3D printing news announced by Thor3D, BEAMIT, JC Steele, Bassetti, BCN3D and more.

New 3D printing developments

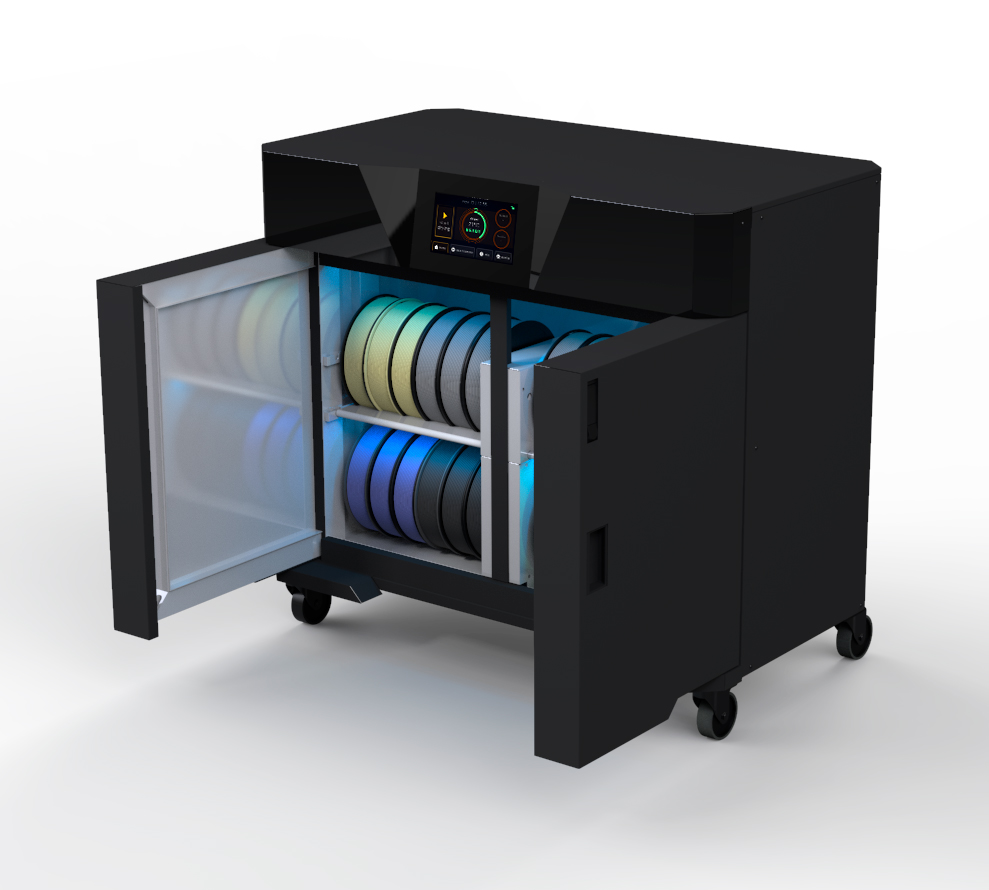

Smart International, the company bringing Kodak’s 3D printer to market, has launched the Smart3D Multimaterial Dryer to eliminate the problems of moisture and keep filaments dry. The USA-based company states, this product is the result of their customers’ requests, since humidity can cause degradation and fragility, and drying by heating can affect the physical and chemical characteristics of the materials.

To ensure consistency and repeatability in 3D printing, Smart International uses a hybrid drying technology, promising a speedy drying, allowing different materials, like PVA, Nylon, and TPU to be dried simultaneously.

Demian Gawanski, CCO of the company said, “With chemical giants strongly stepping onto our industry and broadening its range of applications, it hurts our eyes to see high-performance filament go to waste, bake in ovens or centrifugate in salad spinners. We feel this completes the most comprehensive professional ecosystem on the market and inaugurates our new year of exciting Industry 4.0 compliant releases targeted at exacting customers.”

Japanese multinational imaging and electronics company Ricoh has added an instant 3D print quote function to its website. For the quote, visitors to the website need to upload an STL file and choose the printing technology and materials. Model files can be uploaded in a range of standard CAD formats which are put through automated analysis, file repair and validation checks. The company also offers expert support and online guides for the AM process.

Chilean 3D printing materials company Copper3D observed dermic disorders in amputees and non-amputee patients who use 3D printed prostheses and orthoses. Copper3D explains the phenomenon of bacterial burden in 3D printed medical devices by the porous materials and complex geometries of the prosthetics and orthotics that make them difficult to clean properly.

Cooper3D added a patented additive based on copper nanoparticles, among other carrier and enhancer elements to transform the materials used in 3D printing into fully antimicrobial Nano-Composites. The company presents PLACTIVE, its PLA polymer with active properties in the elimination of a wide range of microorganisms and MDflex, a PETG antibacterial polymer.

Daniel Martínez, Co-Founder and CINO of Copper3D said, “It is surely the beginning of a new revolution in Biomedical 3D printing and the establishment of a new standard in the industry”. To expand in the European market, Copper3D announced its new distribution agreement with Dutch supplier FormFutura.

New and continuous partnerships in the 3D printing industry

After announcing two new bundles for its 3D scanning technology, Russian handheld 3D scanner developer Thor3D has now partnered with Cambridge-based KVS Ltd as well, agreeing on reselling KVS’s reverse engineering software, Quicksurface with the Russian company’s Calibry 3D scanner.

Anna Zevelyov, CEO at Thor3D said, “together with Quicksurface we offer a great solution for those, who just started their path in the 3D industry.” The software is compatible with Autodesk Inventor, Autodesk Fusion 360, SolidWorks, Solid Edge, and other major CAD programs. The model is also transferrable into SOLIDWORKS.

Elsewhere, maintaining the long-term relationship with SLM Solutions, Italian additive manufacturing service bureau, BEAMIT will buy 15 SLM machines within the next three years. The Italian company ordered devices including SLM®280, SLM®500 and SLM®800.

Mauro Antolotti, Chairman and Founder of BEAMIT said, “through the replacement of single laser products with SLM Solutions’ multi-laser technology we are able to increase our productivity and provide competitive pricing to our customers.”

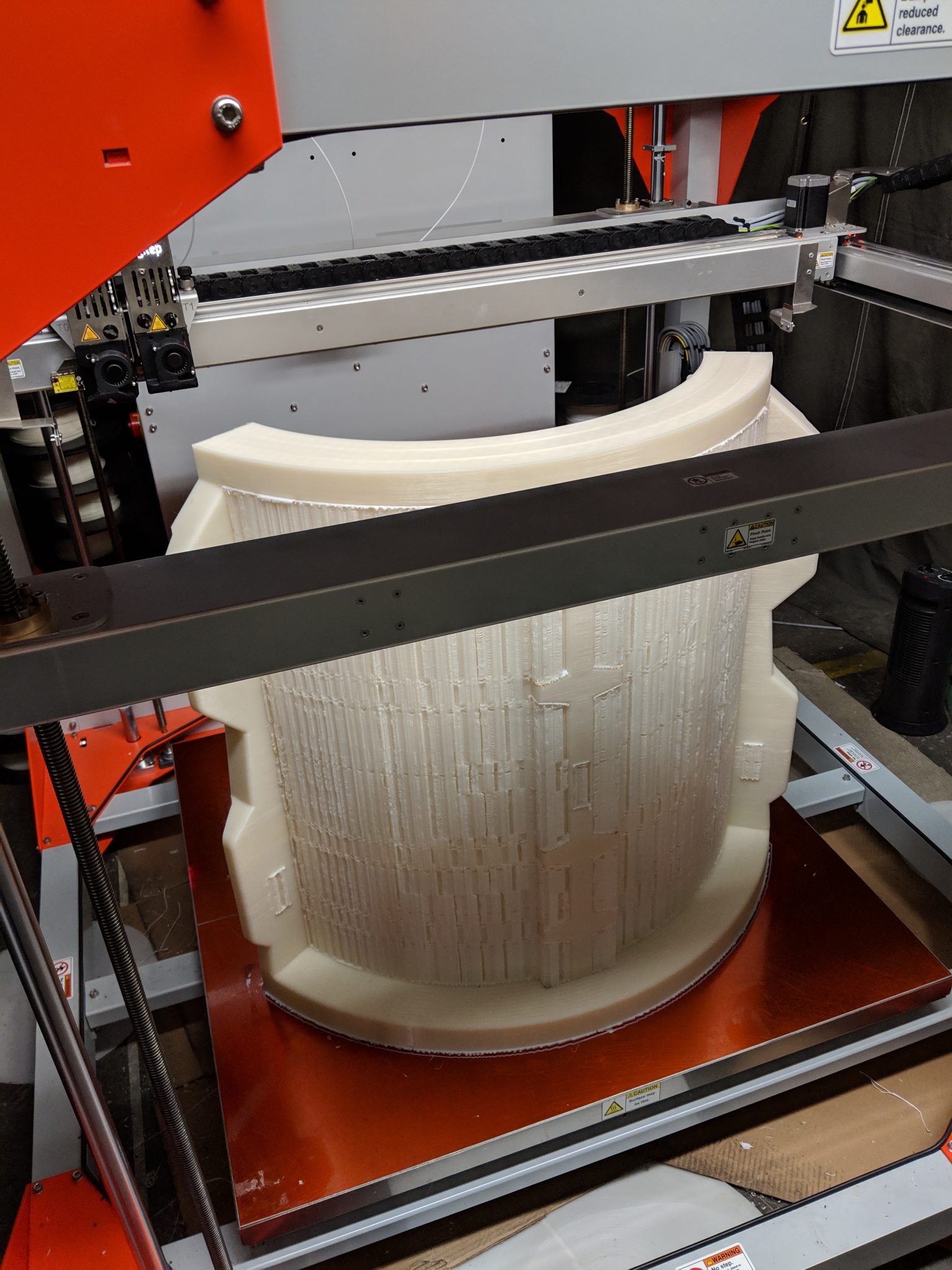

A new working relationship between stiff extrusion machinery company J.C. Steele & Sons Inc. and BigRep was announced. JC Steele is implementing additive manufacturing to develop, test and create the delicate patterns needed for sand casting molds. The company is using a large-format BigRep ONE 3D printer, which has already reduced its expenses by 75% increased annual production by over 50%.

With Berlin-based BigRep’s large-scale 3D printer, JC Steele can print multiple designs of complex parts that vary in crucial differences and also recreate some archive parts no longer available in the market. With the addition of 3D printing technology, the stiff extrusion machinery company has created 60 new patterns in one year.

JC Steele’s Pattern Shop Supervisor, Chris Watts said, “We have streamlined our workflow by eliminating those parts of the design process that are the longest, most fault-prone and expensive ones – the manual designing of a pattern, the interpretation of design drawings and the management of reductive waste.”

Warrington-based 3D printing manufacturer Croft Additive Manufacturing is the latest company, to secured funding through the Made Smarter program. The program supports local manufacturing SMEs and includes expert impartial advice and one-to-one support, digital road mapping workshops and leadership and management training programs to select the right approach for the businesses.

Donna Edwards, Programme Director for the Made Smarter North West pilot said, “We have found a great enthusiasm about the benefits of adopting new digital technology tempered by the uncertainty of how to go about it. It’s clear that the SMEs need the specialist advice and insight to help them select the right approach for their business, how much to invest and which technologies will bring the greatest benefits.”

As part of the North West pilot project, Croft AM is among the 62 small to medium-sized businesses now investing in a range of industrial digital technologies. Made Smarter was launched in November 2018, 300 North West SMEs have received a collective 1.6 million GBP in funding. The 20 million GBP pilot program will run until March 2021.

A new agreement has been executed between Grenoble-based software developer Bassetti and 3D printing database Senvol. Bassetti’s TEEXMA for Additive is an end-to-end solution supporting the complete AM product lifecycle, where from now on, Senvol Database is going to be available, as an integrated source of additive manufacturing data. Through the new partnership, Senvol adds the AM data, while TEEXMA for Additive allows companies to focus on the scheduling, management, and execution of their AM programs.

Bulgarian distributor PrintMe 3D is now selling the 3D printers SIGMA and SIGMAX from the Barcelona-based 3D printing company BCN3D. The Spanish 3D printer manufacturer company partnered with PrintMe 3D to grow in Bulgaria, Ukraine, and the Balkan countries.

Xavier Martínez Faneca, CEO of BCN3D said, “there is a high potential for the IDEX system and the distinctive duplication, mirror and multimaterial printing modes. Their considerable experience in additive manufacturing, combined with top-quality technical know-how makes PrintMe 3D the right fit to help us grow and serve Eastern customers in the best possible way.”

The Barcelona-based company recently reported total revenue of 4.1 million euros for 2019, 17% more than the previous year’s figure of 3.5 million. For 2020, Martínez hopes to improve further since starting to deliver their new 3D printer Epsilon, announced last November.

Voxeljet’s compliance plan approved

The New York Stock Exchange has approved German 3D printer manufacturer Voxeljet’s plan to regain compliance with its continued listing standards. The German company received a letter from NYSE in August 2019, stating that Voxeljet was below compliance with continued listing standards relating to market capitalization and shareholders’ equity.

To regain compliance, the 3D printer manufacturer company submitted its compliance plan in November 2019, recently approved by NYSE. Although, the Stock Exchange may initiate delisting proceedings as appropriate, if the company is not in compliance with the continued listing standards by February 23, 2021, or if it does not make progress consistent with the plan during the plan period.

If you would like to read more about additive manufacturing, subscribe to our 3D Printing Industry Newsletter. Also, keep up-to-date with the latest news by following us on Twitter and liking us on Facebook.

Looking for a job or willing to hire additive manufacturing experts? You can sign up and advertise for free on our 3D Printing Jobs board.

Featured image via J.C. Steele & Sons.