So far TCT 2017 has featured a number of 3D printing hardware and software releases from Ultimaker, Carbon and BCN3D.

With more announcements still to come throughout the week, we have a roundup of some the latest news and exhibits to be released on day one at the NEC in Birmingham.

Hardware previews

Polish 3D printing company ZMorph are exhibiting their new multitool desktop printer, the Z Morph VX.

Online electronics marketplace Monoprice is demonstrating the open source MP Select Mini V2 3D printer “suitable for in-school use and light manufacturing.”

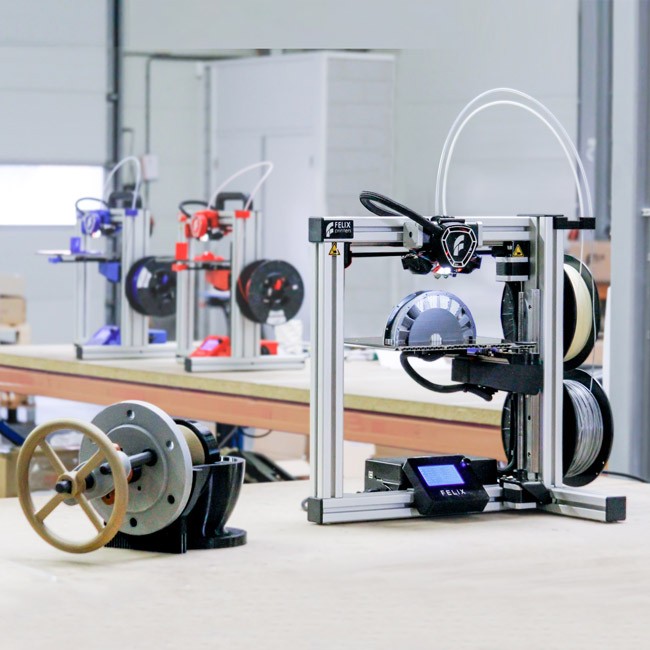

FELIXprinters, based near Utrecht in the Netherlands, has launched a new FFF 3D printer. The FELIX Tec 4 features an improved semi-automatic calibration process, a flexible build plate (to help remove the printed object), and compatibility with a number of filaments. The printer is available both in assembled form and as a DIY kit, where the upgraded and improved parts can be placed on to a Felix Tec 3 printer.

Guyson robotic post processing

Guyson, a family-owned manufacturer based in Skipton, North Yorkshire, has revealed its latest contribution to 3D printing – a robot controlled product finishing station. Known as the Guyson PRS, the system features a blasting function and a powder recovering system. The product is especially aimed at additive manufacturing in the aerospace, medical implant and automotive sectors.

HP’s distribution partnership and new research customers

HP have announced that it will be extending its partnership with German chemical and consumer goods company Henkel. Amended terms in the agreement make Henkel the first global reseller of HP’s Multi Jet Fusion (MJF) 3D printers.

The company has also announced a string of new high-profile customers across Europe, including Danfoss Group, ETH Zurich, Jaguar-Land Rover, KTM, and The Manufacturing Technology Center.

Stratasys corner eyewear market

Stratasys have developed a Veroflex Rapid Prototyping solution to reduce design to market time for spectacles and the process more cost-efficient. The Veroflex material, printed using a J750 polyjet 3D Printer aims to produce “precise, functional models” whilst maintaining a stiff yet flexible material.

Tackling the 3D printing trifecta

The materials #3DTalk panel hosted by Women in 3D Printing’s Nore Touré was a hit at the show’s Tech Stage. Speaking on the selection of this year’s topic Touré highlighted the “3D printing trifecta” commenting, “When talking about 3D printing and what advances the technology, a few things come to mind: use of the technology of course, but also, hardware, software and… materials.”

“We believe it is important to have a dedicated talk about why and how to market and advance new materials for 3D Printing […] We wanted to cover the question of materials on a large scale, not focusing on one 3DP process rather than [an]other.”

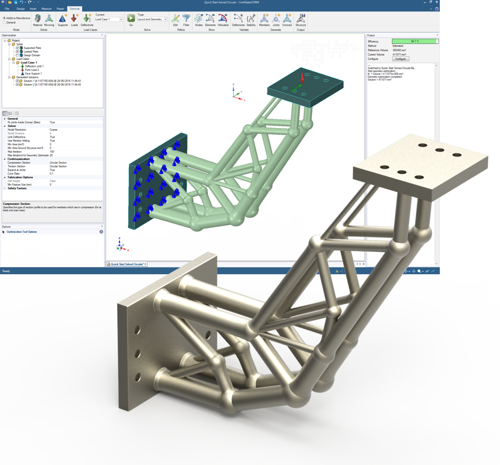

Industrial strength .stl fixing

LimitState, a developer of analysis and design software for engineers is exhibiting it’s recently released LimitState:FORM software for optimization of CAD files.The technology is based on research conducted at the University of Sheffield’s Centre for Advanced Additive Manufacturing. It is also exhibited alongside the firm’s “industrial strength STL file fixing tool” LimitState:FIX.

For updates on the latest from TCT 2017, subscribe to our free industry newsletter, like us on Facebook and follow us on Twitter.

Find more 3D printing events near you here.

Featured image shows Stratasys demonstrating 3D printing applications for McClaren at TCT 2017. Photo by Michael Petch for 3D Printing Industry