Sometimes equations yield some surprising results. We like to think of 3D printing and crowd sourcing as potential alternatives to mass production, but what happens when something that you crowd sourced and 3D printed becomes so popular that your four 3D printers, working 24/7, cannot meet volume demand? After a well deserved celebration you might want to invest in injection moulding.

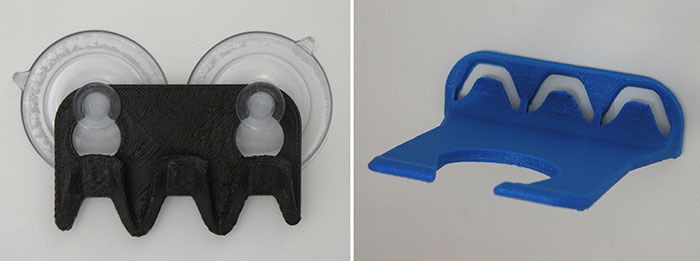

That’s what happened to Michal Aylesworth and his Wave Hooks. After two successful crowd sourcing campaigns allowed him to begin production and sale of his innovative suction cup (and/or 3M tape) holder, demand for it – especially the Wine Glass Holder model – became so high that he went ahead and set up a third – already successful – campaign (the second on Indiegogo) to get them injection moulded. The goal? A whopping $500 (tripled with 33 days left) but enough to ensure a few more runs and a few more happy Wave Hook owners.

Interestingly you can back the mass produced run by purchasing a 3D printed version of the Wave Hook that you will receive in June/July, or you can invest directly in the injection moulded versions (likely to have a smoother finish) and receive them in August. I guess it’s not about thinking of this as a defeat for 3D printing’s mass production potential as much as a great example of different technologies working together to give everyone what they want, when they want it.