A team of researchers at King’s College London (KCL) have discovered how to make house bricks capable of generating their own electricity. Completed by a 3D printed core, the blocks require no recharging and could generate power for an indefinite period of time.

The team behind the bricks believe they could have a significant impact on the construction of temporary and remote shelters – providing lighting at night and enough electricity to charge mobile phones.

Electric bricks

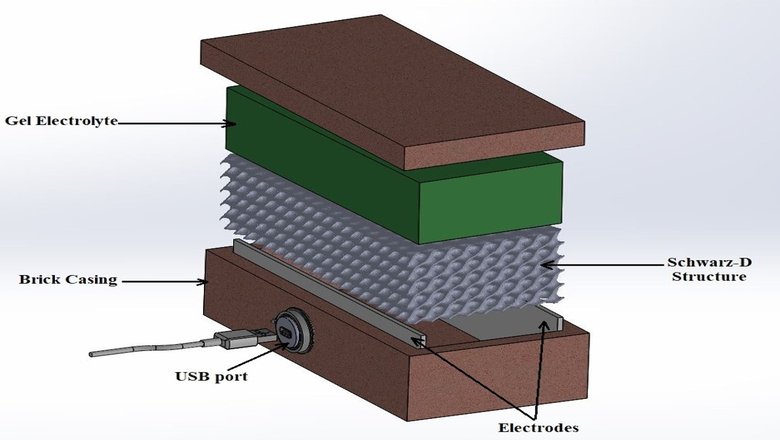

KCL’s bricks are a type of thermogalvanic cell and rely on an imbalance in temperature. When one face of the brick is colder than the other, electrons inside the brick attempt to reach equilibrium. Their movement in turn creates electricity which can then be extracted through the addition of a plug socket or USB port.

To enable this electrochemical process, and strengthen the would-be typical house brick, the structure is reinforced by a plastic Schwarz D gyroid structure and an electrolyte gel.

Dr. Leigh Aldous, senior lecturer in the Department of Chemistry at KCL, explains, “The idea is that these bricks could be 3D printed from recycled plastic, and be used to quickly and easily make something like a refugee shelter.”

“Crucially,” Dr. Aldous adds, “they do not require maintenance, recharging or refilling,”

“Unlike batteries, they store no energy themselves, which also removes risk of fire and transport restrictions.”

3D printed power

3D printing’s use is power/electricity generation is incredibly varied. Recently, at the Stevens Institute of Technology, New Jersey, scientists applied a kind of direct write 3D printing method enabling mushrooms to produce electricity. Furthermore, at ETH Zürich, researchers under the direction of Professor Kristina Shea developed a battery and fuel free submarine that operates using 4D printed mechanisms.

The KCL team developed its innovative brick structure in collaboration with PLuS Alliance partners Arizona State University and UNSW Sydney, and they have put a provisional patent in place for the device.

Could the KCL group be your Research Team of the Year? Make your nominations now in the 2019 3D Printing Industry Awards now.

For all the latest research updates subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit 3D Printing Jobs to get a head start.

Featured image shows structure of the KCL developed thermogalvanic brick. Image via KCL