A 3D printed violin could bring this classical instrument to the next generation if the 3Dvarius Kickstarter reaches its goal.

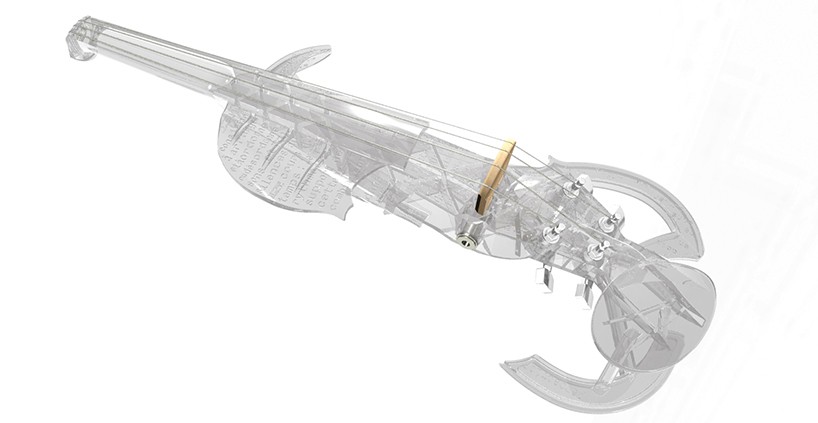

This electric violin is a futuristic work of art made from transparent resin and it looks amazing. Freed from the constraints of traditional acoustic design, musician Laurent Bernadac and his team have managed to create an ornate sculpture.

Is this a world first?

The company behind this stellar piece of art claim that it’s the first fully printed and playable electric violin. They also believe that by bringing modern technology together with age-old skills, they can create a better violin with a supreme natural balance that brings out the best in the musician.

It’s easy to see why. With an integrated rest and almost all of the superfluous material stripped away, the lightweight 3Dvarius gives the musician everything they need and nothing they don’t. This gives them the ideal instrument that just gets out of their way and allows them to produce a stunning piece of music, time after time.

The design isn’t just about the aesthetics and the weight, either. It has been optimised at every stage to ensure the best quality sound. It is also vital that the body of the violin can provide enough resistance to the strings.

3Dvarius is aiming at the elite

This is essential for a concert level violin and there is little doubt that 3Dvarius is aiming at the connoisseur. Of course each design can be unique and the company will certainly be able to enhance the basic shape according to each violinist’s particular requirements.

The first one has a vast amount of music-related text on the frame, for instance, which could easily be changed to something more meaningful for the individual or even a particular piece of music for a big event.

Kickstarter campaign goes live

The $50,000 Kickstarter campaign will help them perfect the stereolithography process and also to continue to perfect the material compound to get the right resonance. There will be no real mass production here, each piece will be painstakingly deburred and polished once the printer has worked its magic on the basic shape.

It will then be UV polymerised, polished once again with the finest grade sandpaper and only then will the strings and neck go on. Then it just needs a tune and it is ready to blow the roof off the concert hall.

There’s a very clear nod, in the name and the philosophy, to Stradivarius. These mythical violins often trade hands for more than $1 million and The Messiah Stradivarius is valued at $20 million. http://www.cmuse.org/12-most-expensive-violins/

In fact, as the instrument is made from a single piece, the sound could be even better. It is totally uniform, which is a major departure from traditional instruments that are made of a mass of separate parts. That allows for a smooth, optimised soundwave to flow through the instrument, which gives the musician a greater degree of control.

A huge market in the making?

There is a potentially huge market for 3D printed instruments and there’s a good reason for the technology to take over. Fewer parts means a more consistent tone, which the industry is crying out for. Musicians, especially those with string instruments, are forced to tune their equipment almost before every session. 3D printing gives a greater degree of consistency, a more rigid shape to the violin, guitar or cello and it should provide a more solid base.

The only sticking point might be the price. 3Dvarius has yet to reveal the sticker price on this stunning violin, but we suspect it won’t be cheap. Still, it’s a beautiful thing and we hope to see and hear it in action before too long.