A research consortium set up to accelerate the certification and qualification of 3D printed metal parts is to be given a share of $2.7 million, provided by the U.S. Department of Defense Office of Economic Adjustment Funds. Of the fund, approximately $1.5 million will be shared between the Colorado School of Mines and the Alliance for the Development of Additive Processing Technologies, known as ADAPT.

Efficient and expansive deployment of additive manufacturing processes

ADAPT is a research and development organization, working in collaboration with the University of Utah, to develop technologies for industry wide and governmental classification of additive manufacturing. Aaron Stebner, ADAPT Technical Director, describes it as follows,

This program creates a new manufacturing platform to advance economic and workforce resilience in response to changes in defense spending. Enabling manufacturers to efficiently deploy additive manufacturing processes helps diversify their product offerings, expand into non-defense markets, and provide resilient employment and value to their communities and the economy independent of defense spending.

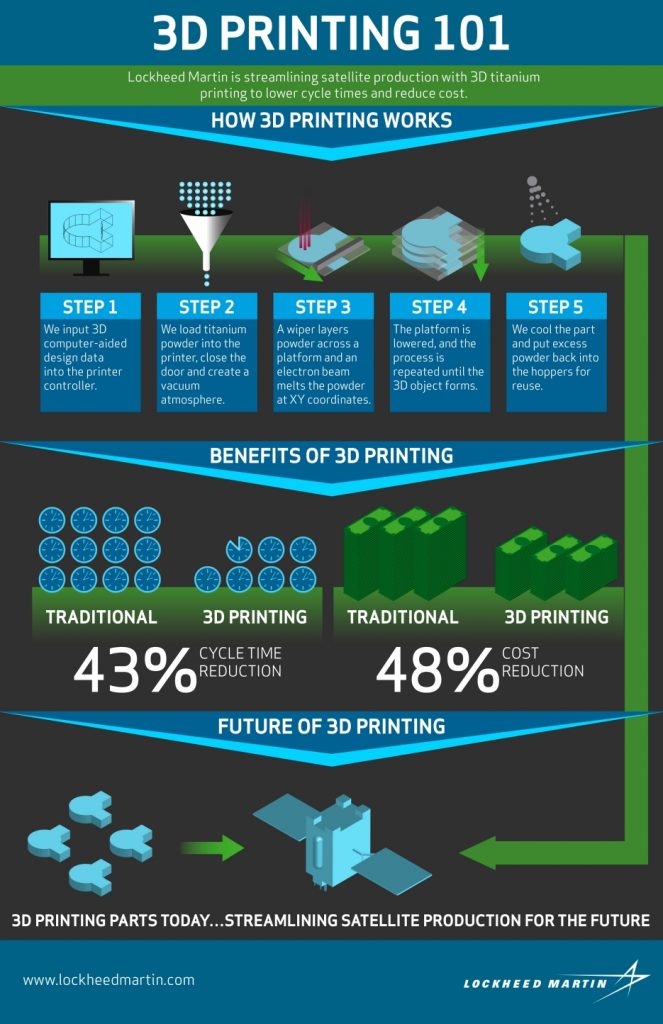

Founding members of the program from the manufacturing industry include Ball Aerospace & Technologies Corp., Faustson Tool, Citrine Informatics and Lockheed Martin, who shared their vision of the industry with us as part of the Future of 3D Printing series. Lockheed Martin, amongst 150 manufacturing, and additive manufacturing organizations, are also contributors of America’s additive manufacturing roadmap.

Additive infrastructure for advanced manufacturers

ADAPT have developed a data infrastructure for product and material changeovers for metals and processes in the industry. It is implemented in the Mountain West Advanced Manufacturers Network (MWAMN), as explained by ADAPT industry board chair Heidi Hostetter,

Additive manufacturing holds the promise of enabling manufacturers to quickly adapt to changing market needs compared to traditional manufacturing methods Today, building new parts or switching materials with this technology takes too long. MWAMN is focused on radically shortening that time, lowering costs, and reducing the negative economic impact on companies and communities when defense programs and spending changes.

The DoD are contributing the full $2.7 million fund to the MAWMN. Other members of the network include Manufacturing Extension Partnership organizations in Colorado and Utah from the National Institute of Standards and Technology (NIST), that itself has contributed $7.4 million in grants for additive manufacturing research.

For more of the latest additive manufacturing news sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.Don’t forget to vote in the first annual 3D Printing Industry Awards.

Limited tickets for the 3D Printing Industry Awards are also now available here.

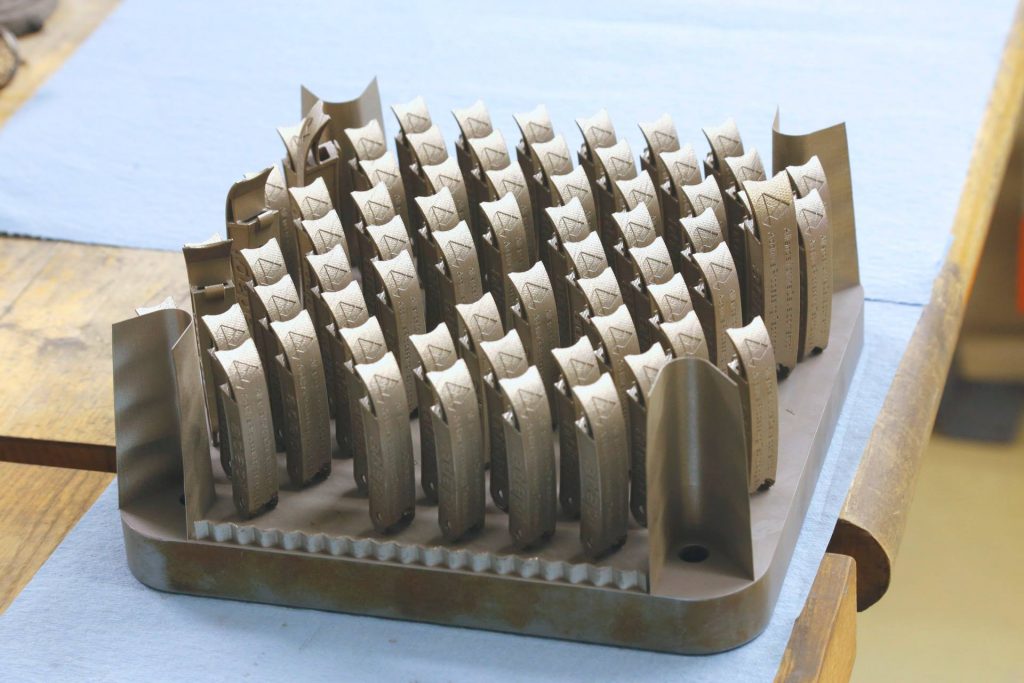

Featured image: Concept Laser LaserCUSING technology adopted by ADAPT as one method of metal 3D printing. Photo via Concept Laser