The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Researchers at Santa Clara University have used 3D printing to build an upgraded version of the hydration sensing units deployed in agricultural irrigation systems.

By redesigning, 3D printing and iterating on parts of these sensors, the engineers have been able to improve their thermal detection capabilities, and shrink their overall size. In doing so, the team has also managed to reduce their cost, thus farmers could now feasibly use such sensors on a broader scale than before, to ensure that valuable vegetation or exotic herbs are watered sufficiently to flourish.

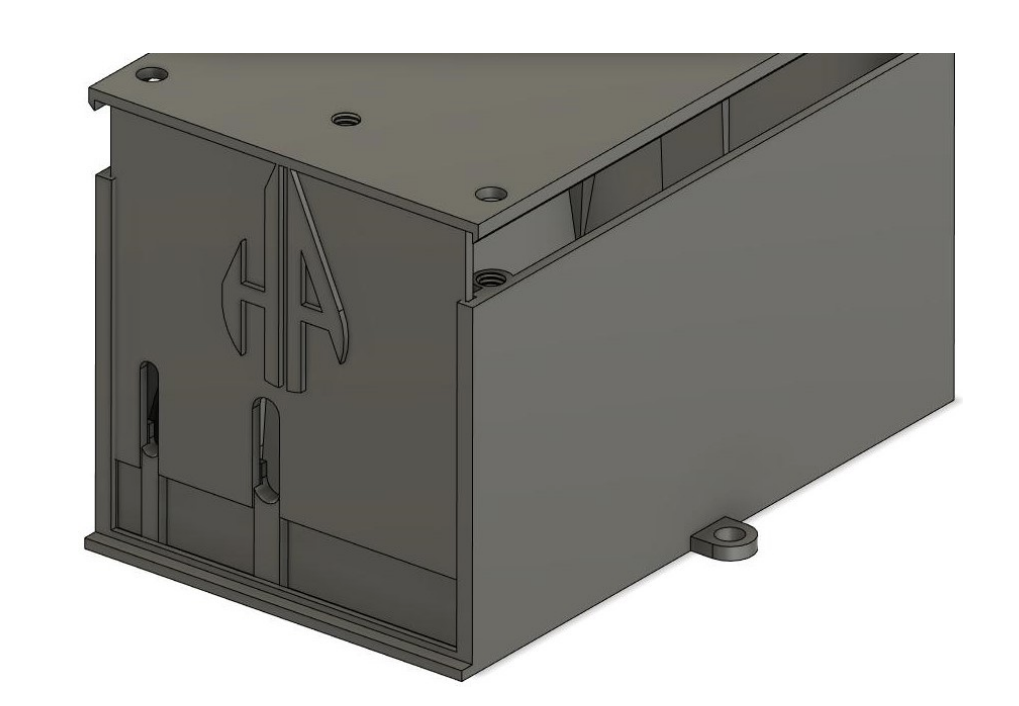

“By upgrading to more efficient components, creating a compact and modular design, and crafting a custom 3D printed shell, our Sensing Unit (SU) was upgraded into a much more powerful hardware system,” said the researchers in their paper. “Our hydration automation system has been adapted to be a much more capable and widely-applicable Internet of Things (IoT) solution.”

Exploring agricultural automation

When deployed in outdoor settings, so-called Internet of Things (IoT) systems such as agricultural automation technologies, effectively enable farmers to monitor their crops from afar. In practise though, such setups require the use of small-but-sensitive nodes, capable of detecting how much moisture a given plant needs, and relaying this information back to a controlling server.

During usage, these sensing units are often left exposed to direct sunlight, meaning that they’re subject to humidity and extreme temperature fluctuations, which can affect their performance. Back in 2019, the Santa Clara team attempted to overcome these potential issues by creating their ‘AB’ in-house routing protocol, which allowed units to interact with servers through a more robust subsystem.

However, the team found that their sensing device itself still “had room for improvement,” thus they’ve now turned to 3D printing as a means of realizing a more compact design, optimizing their unit’s detection capabilities and making it energy-efficient, as well as cheaper to manufacture and ultimately more scalable than existing alternatives.

Sensing a market opportunity?

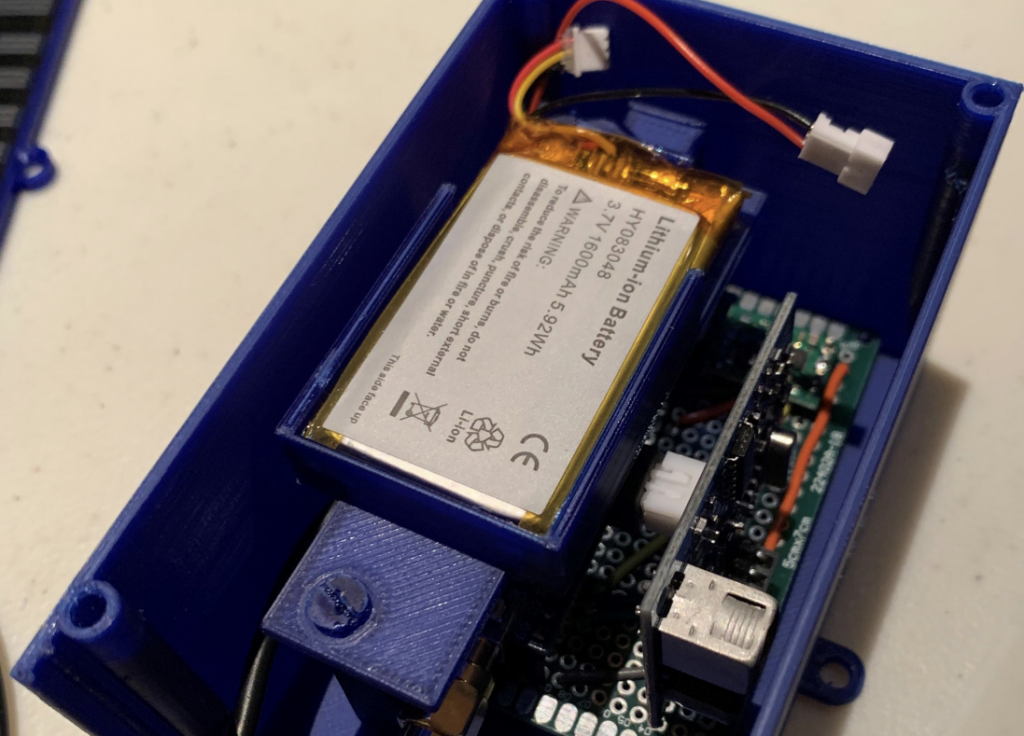

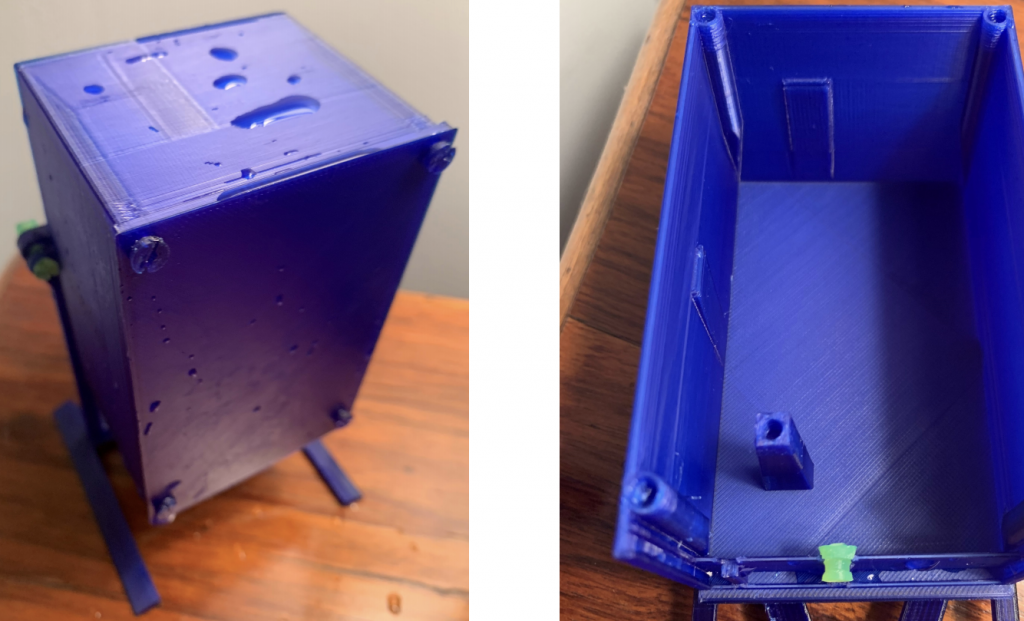

Nicknamed Sensing Unit 2.0 or ‘SU 2.0,’ the researchers’ upgraded device features a node board, communications module, ultrasonic sensor, thermal sensor, voltage regulator, battery and solar panel. Housed within a 3D printed capsule, the SU 2.0’s components are divided up by printed separators, which allow users to upgrade parts where desired, without risking damage to any surrounding compartments.

According to the team, their device’s voltage regulator has also become critical to the unit’s design, as is enables the unit’s battery to operate at 3.6v and its ultrasonic sensor to run at 5v, and through sheer rejigging ingenuity, the engineers have been able to make the SU 2.0 operate around 15% more energy-efficiently than the SU 1.0.

In terms of hardware additions, one of the biggest upgrades the researchers have made to their device is the introduction of a thermal module. Working in tandem with the SU’s algorithm, the sensor can now relay any weather or temperature-related information to a central server, where this can be analyzed and used to recommend potentially crop-saving actions to farmers.

Likewise, given that their SU is likely to be deployed outdoors (except when growing certain herbal remedies), the team 3D printed its casing from rain-resistant PETG. The sensors have also been designed to feature overhangs on its sides, as a means of closing the gaps required for the unit to slot together, while its internal cables are lifted inside, to prevent them from getting wet during heavy showers.

In order to put all these upgrades to the test, the team eventually subjected their device to power and waterproofing evaluations. Although initial results showed that no water was able to contact the capsule’s circuitry, it was able to run on stored power for over a week without sunlight, and it cost just $62 to build, the researchers have now identified further performance enhancements for their farming system.

As well as fitting their units with Wi-Fi and magnetic connectors instead of screws, the researchers are also looking into the possibility of drawing on data trends and weather monitoring schedules to water crops more evenly. Overall though, they consider the SU 2.0 to be a marked improvement on their previous design, and thanks to its 3D printed casing, they say it may even have mass-market potential.

“SU 2.0 has improved upon many limitations of the previous iteration such as energy efficiency and size, while offering new features such as improved waterproofing,” concluded the team in their paper. “The SU improvements have enabled the mass-production, real world deployment, and utilization of small form factor and cost-effective-yet sustainable IoT SUs for hydration automation.”

3D printing climate sensors

Oddly, the Santa Clara team’s sensors don’t represent the first time that 3D printing has been used within farming, as agriculture start-up Dragontech has recently taken a similar approach. Using MakerBot machines, the firm now designs and prototypes parts for its drone data gathering platform, which helps farmers identify any potential issues in their fields.

Elsewhere, such 3D printed sensors have often found pollution-detection applications. In September 2020, for instance, the French National Research Institute for Development (IRD) used Formlabs’ technology to produce an ultra-low-cost device for underwater environmental detection, which allowed it to accurately survey the country’s water quality.

Similarly, Singapore-based Sensocore has previously announced a switch to additive manufacturing, as a means of streamlining the production of its Aquafarm Water Sensor Systems. The firm’s detection devices are designed to pick up temperature and acidity changes in water-based farms, before alerting farmers to anything that seems fishy.

The researchers’ findings are detailed in their paper titled “SU 2.0: A Marketable Low-Power Wireless Sensing Unit for Hydration Automation,” which was co-authored by Navid Shaghaghi, Nicholas Kniveton, Jesse Mayer, Will Tuttle, and Peter Ferguson.

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper-dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the contents of the researchers’ 3D printed hydration sensor casing. Photo via Santa Clara University.